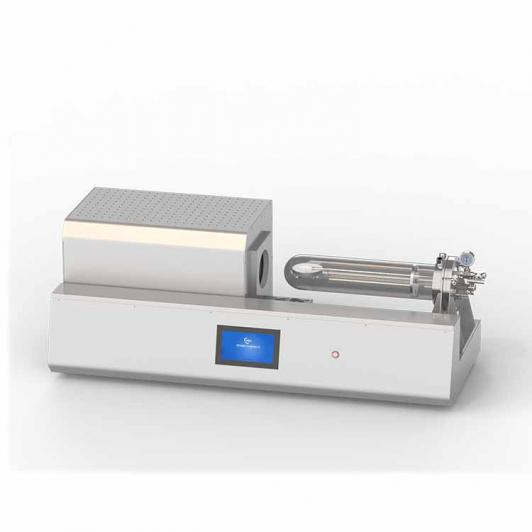

purification furnace is a fire refining method that deeply purifies metals, metal compounds or changes the distribution of impurities in metal ingots. Its essence is to form a narrow melting zone (melting zone) by locally heating a long and narrow metal ingot. And make it move slowly along the ingot in a certain direction,

and use the difference in the equilibrium concentration of impurities between the solid phase and the liquid phase to segregate the impurities into the solid phase or the liquid phase. Repeated operations can redistribute the impurities to one end of the ingot or Both ends. By removing the part with high impurity content, high purity metal can be obtained. At present, 1/3 of the elements and hundreds of inorganic and organic compounds can be purified to very high purity by means of zone smelting. Because the impurity diffusion rate is usually slow, the speed of the melting zone must be very slow each time during the completion of the zone smelting purification process, generally in the order of tens of millimeters/hour, and the purification operation needs to be repeated many times to achieve the specified The purity. The key to improving zone smelting efficiency lies in the control of the melting zone, including the width of the melting zone, the stirring of the melt, and the speed and stability of the movement of the melting zone. In addition, it is necessary to consider the pollution of metals such as oxygen, nitrogen, carbon and other elements in the air during the smelting process, and it is necessary to control the vacuum or inert atmosphere in the regional smelting device.

purification furnaceThe work process:

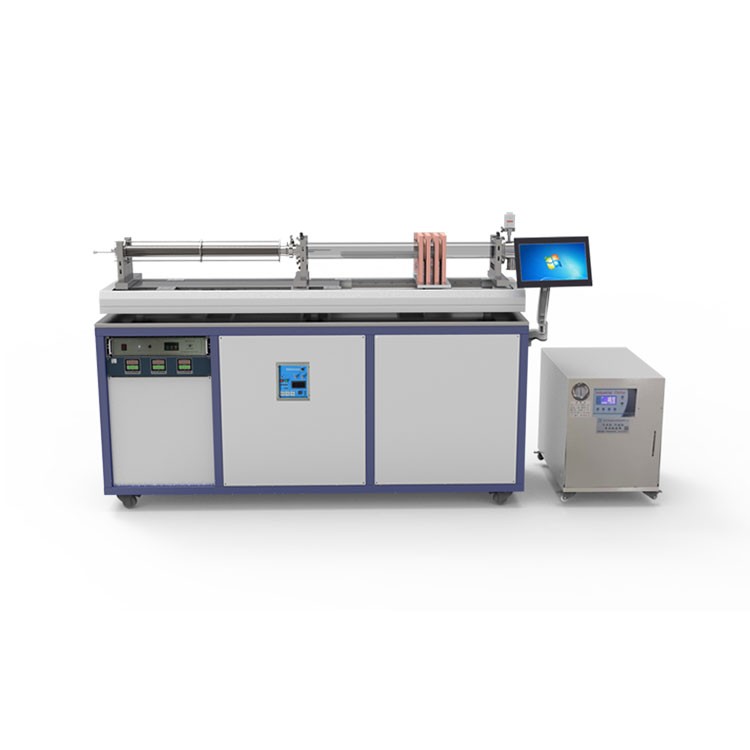

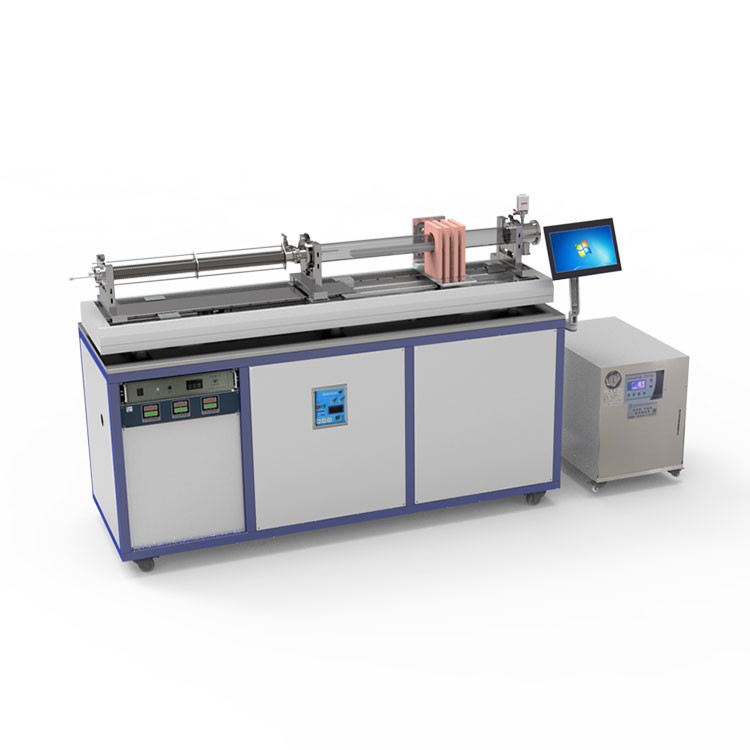

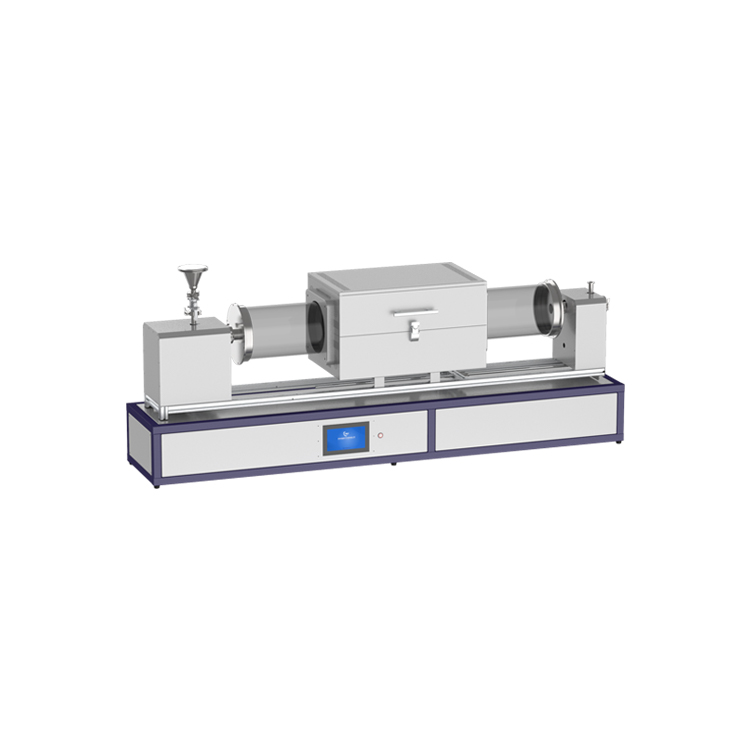

1) After smelting indium, tin, bismuth, lead or zinc with a purity of 4N (99.99%) or higher, cast them into metal rods and place them in a quartz boat with a length of 500 mm and a clean surface.

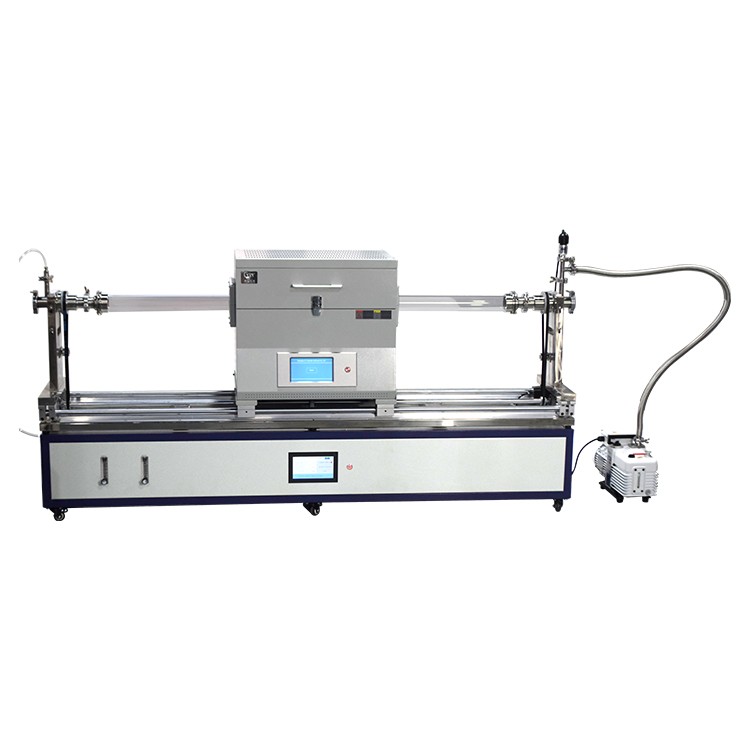

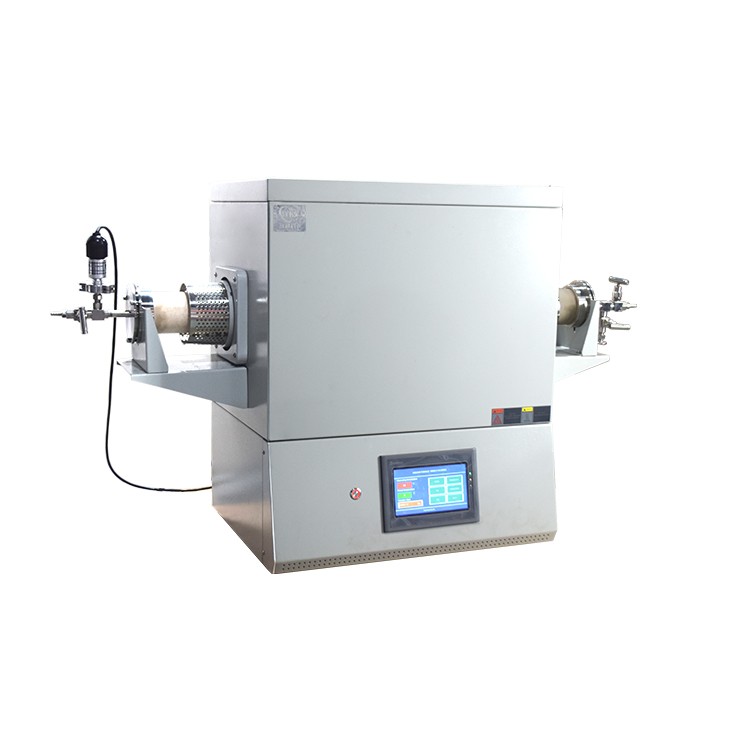

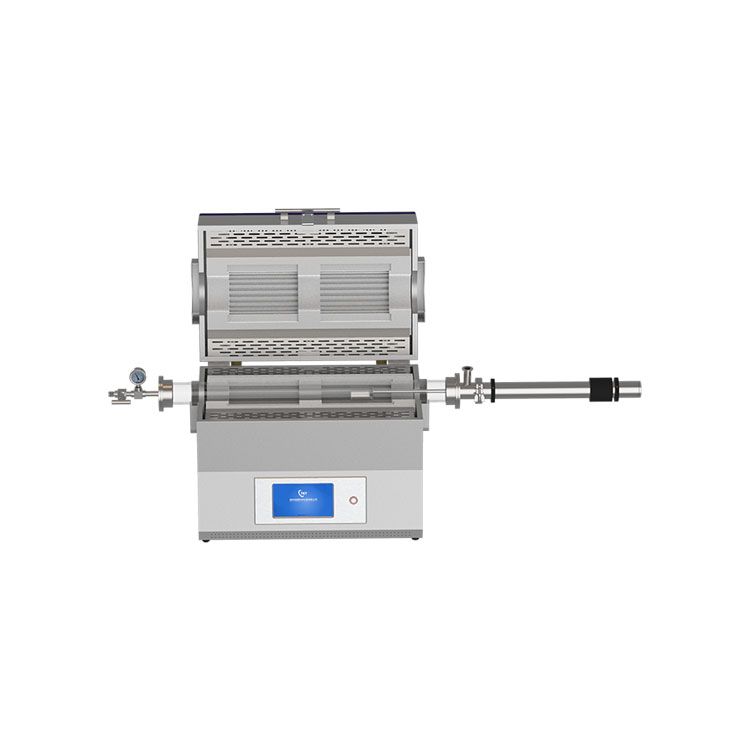

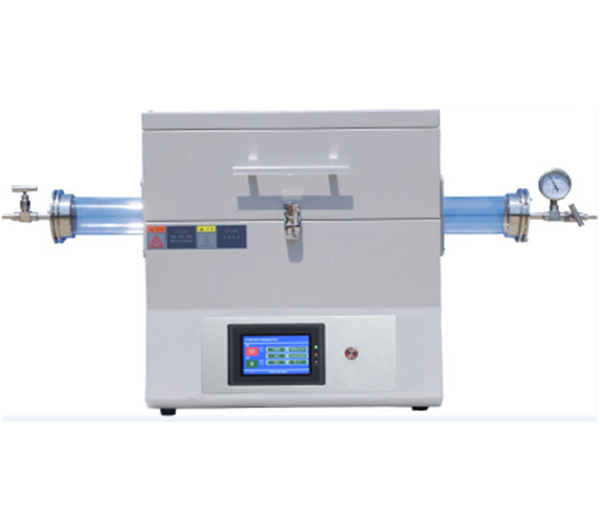

2) Place the quartz boat in a quartz furnace tube with a length of 1000mm and a diameter of 60mm. The two ends of the quartz tube are sealed with a vacuum flange to form an airtight structure; one end of the flange is connected to a vacuum pump, and the other end is connected to a high-purity argon purifier.

3) Install the electromagnetic shielding baffle and ceramic bracket on both sides of the induction heating coil, keeping the distance between 10~40mm;

4) Open the three-way valve on the seal at the right end of the quartz furnace tube to communicate with air; then open the argon cylinder and start the high-purity argon generator, and at the same time open the high-purity argon control valve on the seal at the left end of the quartz furnace tube to pass in the high-purity argon Pure argon (>99.9995%) for 5-10 minutes; turn the three-way valve at the right end to turn on the vacuum pump, then close the high-purity argon control valve at the left end, and then start the vacuum pump to pump the vacuum in the quartz furnace tube to 10-3Pa Close the three-way valve at, to complete the first gas exchange operation; then open the high-purity argon control valve on the left end seal to pass in high-purity (>99.9995%) argon, and close the high-purity argon control when the pressure is 1atm And turn the three-way valve at the right end to turn on the vacuum pump to pump the vacuum in the quartz furnace tube to about 10-3; repeat this two more times to finally complete the ventilation operation to ensure that the air in the vacuum tube is completely filled with high-purity argon After that, in the process of regional smelting, always close the three-way valve, open the high-purity argon control valve, and keep the high-purity argon pressure at 1atm.

5) Pass the induction heating coil made of red copper tube and the quartz spiral cooling tube with cooling water; then start the high-frequency power supply, set the output voltage to 40-70V, the output current to 10-30A; the frequency is 1-30KHz; observe the melting zone After it is normal, start the stepping motor numerical control table, and under the control of the controller, drive the quartz furnace tube to move at a constant speed from left to right at a speed of 5-30mm/hour to the metal indium, tin, bismuth, lead or zinc in the quartz boat Smelt all once and stop.

6) Turn off the high-frequency power supply, and then retract the stepping motor numerical control table to the initial position; then restart the high-frequency power supply and the stepping motor numerical control table, restart the purification operation, and repeat this 10-16 times.

7) Turn off the high-frequency power supply and the stepping motor numerical control table, and at the same time turn off the circulating water, but keep the pressure of the high-purity argon at 1atm; After the purified high-purity metal indium, tin, bismuth, lead or zinc is cooled to room temperature, turn on the right With the side sealing head, take out the quartz boat and put it into a glove box protected by an argon atmosphere.

8)Sampling and analyzing the distribution of impurities in high-purity metals, cut off the parts with higher impurity content, and seal the remaining high-purity (above 6N) metal indium, tin, bismuth, lead or zinc with plastic packaging

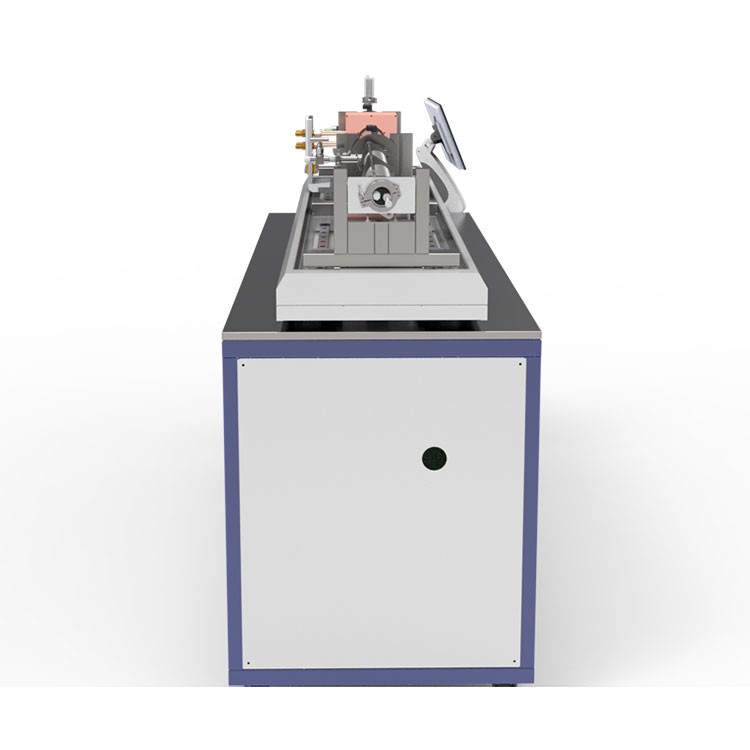

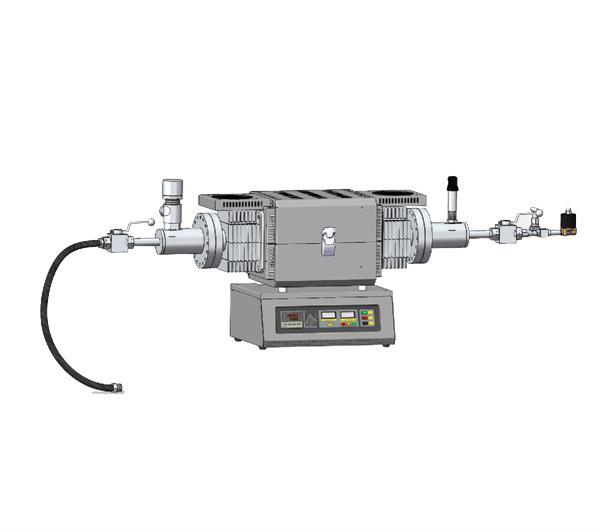

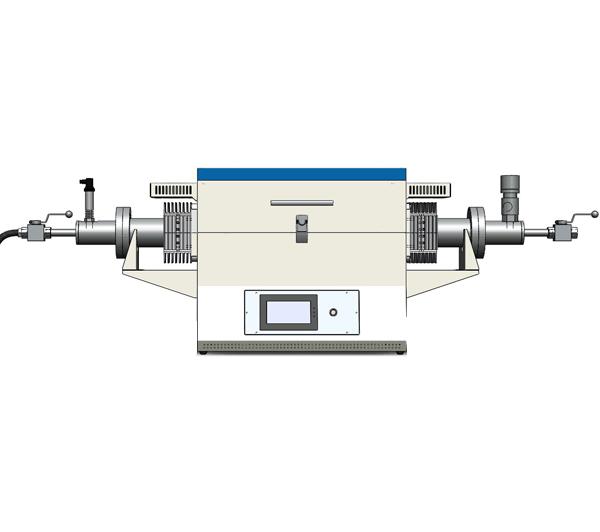

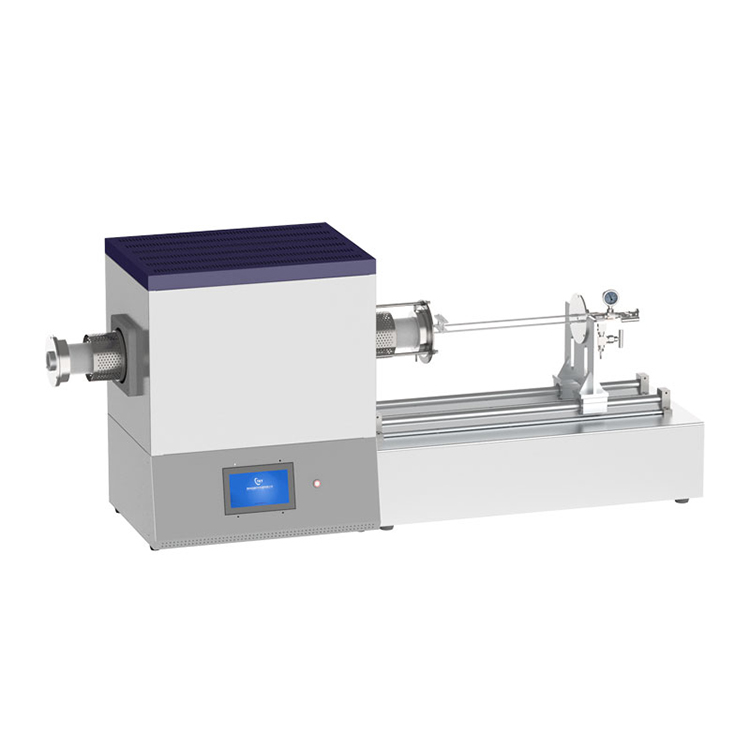

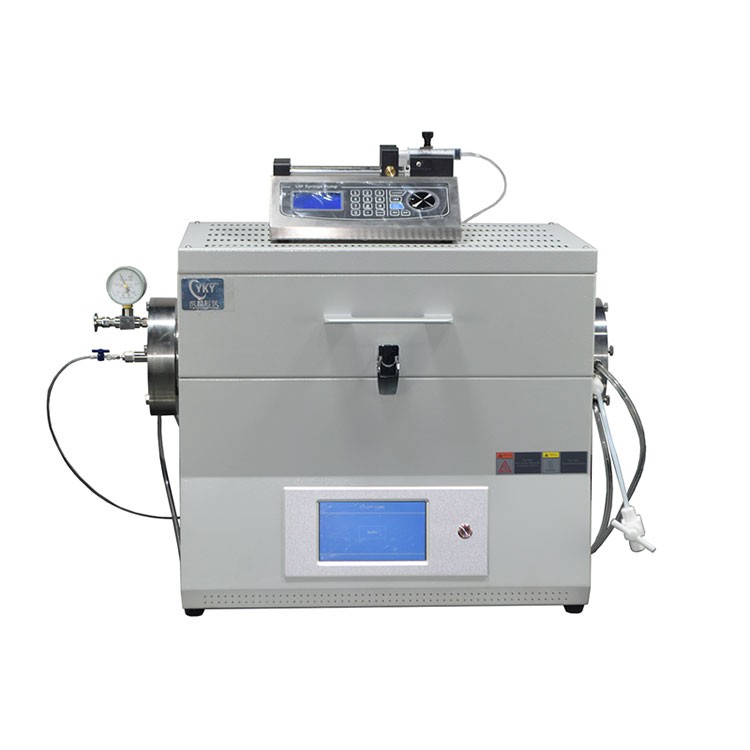

The main technical parameters of purification furnace:

product name: | Induction type electromagnetic shielding area purification furnace (CY-TPF800-I60) |

Power supply: | AC220V 50/60Hz |

Power: | 25KW |

Diameter of furnace tube: | 60mm |

Furnace tube length: | 1000mm (5 melting zones, temperature gradient can be set and maintained) |

Quartz boat size: | Length 500mm |

Gas control: | Mass flow controller |

Flow range: | 0~500SCCM |

Working gas: | High purity argon |

Vacuum acquisition: | Molecular pump set |

Cooling mode: | Water cooling unit |

Heating mode: | Induction heating |

Operating temperature: | Room temperature~1000℃ |

Temperature measurement: | K-type thermocouple |

Temperature control accuracy: | ±5℃ |

System vacuum: | 4.4×10-3Pa |

Vacuum measurement: | Compound vacuum gauge |

Pumping speed of molecular pump: | 600L/S |

Fore pump: | VRD-4 |

Pumping speed of backing pump: | 1.1L/S |