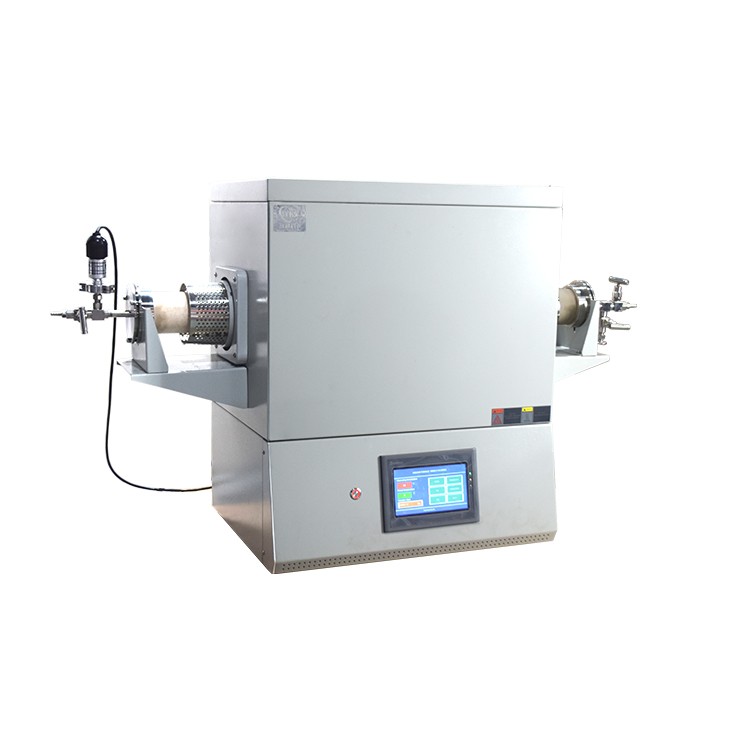

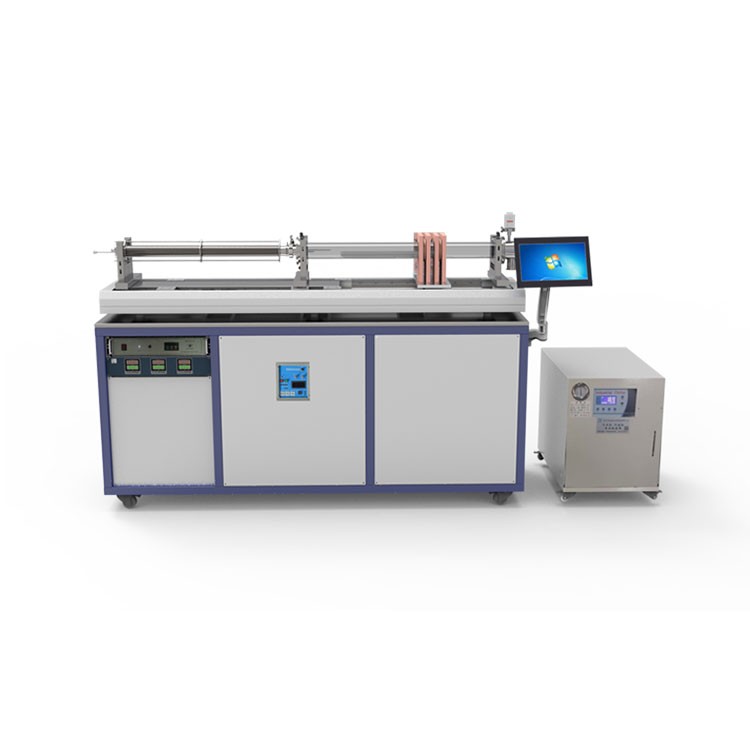

Furnace Structure | Using one of tube furnace and modifying into vertical Temperature range is optional from 1200 ℃ to 1700 ℃ |

Max. Temperature | 1200 ℃ - 1600 ℃ selectable |

Tube Size and Materials | |

Force Sensor | Force Sensor output data will connect to PLC or PC to show weight change curve with temperature |

Crucibles | One 25Dx25H (mm) alumina crucible is included. Please click Pic. 1 to order more You may click Pic. 2 to choose ZrO2, BN, or Y2O3 crucible based on your application The customized crucible is available upon request

|

Temperature Controllers | Programmable temperature controller ( Europe there for precise control of heating rate, cooling rate and dwell time. Built-in PID Auto-Tune function with overheating & broken thermocouple broken protection. Over-temperature protection and alarm allow for operation without attendant(s). +/- 0.1 ºC temperature accuracy. One K-type thermocouple. RS485 Communications Port.

PC control software and interface module are included |

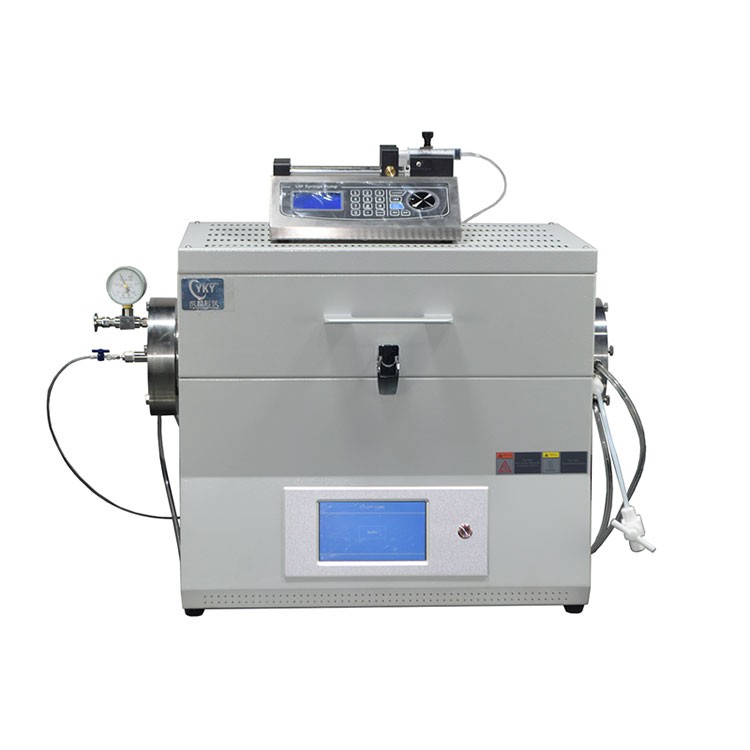

Vacuum | A KF25 vacuum port is built-in to connect a vacuum pump Achievable vacuum level depends on the selected vacuum pump Click the Picture below to order a vacuum pump separately

|

Gas Delivery (optional) | You may connect the TGA furnace with MTI multi-channel gas delivery system for mixing gas operation, or oxygen or a gas analyzer to the gas outlet port |