The method of preparing ZnO:Eu thin film with ultrasonic atomization pyrolysis spraying machine: respectively configure the concentration of 0.4mol/L zinc acetate (Zn(CH3COO)2) aqueous solution and 0.4mol/L (Zn(CH3COO)2), Europium chloride (EuCl3) mixed aqueous solution. The transparent conductive ITO substrate was cleaned by ultrasonic cleaning with acetone and ethanol for 10 minutes. Pour the prepared precursor solution into an ultrasonic atomizer to prepare ZnO and ZnO: Eu thin films. Adjust the nozzle height to 1.5cm, preheat the substrate for 5min, and set the spray time to 30min. The aqueous solution is ultrasonically atomized, transported by carrier gas, and sprayed on the ITO substrate that has been heated to a certain temperature. The atomized droplets undergo thermal decomposition reaction on the surface of the substrate. After spraying, the film is naturally cooled to room temperature.

The fuel cell proton exchange membrane PEMFC was prepared with an ultrasonic atomization pyrolysis sprayer: the proton exchange membrane Na-fion212 was pretreated with 3% H2O2 solution, 0.5mol•L sulfuric acid solution and deionized water to remove impurities. The binder used in the electrode is Nafion solution produced by DuPont. The catalyst uses a catalyst with a platinum content of 40% (mass fraction) from Johnson Matthey. The carbon microporous layer (MPL) and the catalytic layer (CL) were prepared by using ultrasonic spraying equipment (USI, USA). Among them, the platinum loading of the cathode catalyst layer is 0.55 mg•cm~, and the platinum loading of the anode catalyst layer is 0.05, 0.10, and 0.30 mg•cm~. The carbon paper (cathode, anode) sprayed with the catalytic layer and the microporous layer and the proton exchange membrane are combined by hot pressing to successfully prepare the membrane electrode.

Preparation of MgO film by ultrasonic atomization pyrolysis spraying machine:Dissolve an appropriate amount of MgO (99.9%) powder in nitric acid (HNO3) with a concentration of 30% (wt, mass fraction, the same below) to prepare a precursor solution with a concentration of 0.5 mol/L, and set the growth chamber (Composed of a large quartz test tube and a small quartz tube nozzle, the distance between the two is about 5 cm, and the nozzle diameter is 10 mm)temperature to 550 , 600, 650 and 700°C. The atomized precursor liquid is sprayed out through a small quartz tube nozzle in the growth chamber, when it encounters a substrate that is placed obliquely [Single crystal Si substrate with single-sided polished substrate (20mm×20mm×1mm)],after a series of processes such as the thermal decomposition reaction of the solute, the MgO film is prepared.

AZO film is prepared by ultrasonic atomization pyrolysis sprayer: AZO film is deposited on a single crystal silicon substrate, the precursor solution is zinc acetate (Zn (CH3COO) 2.2H2O) and aluminum nitrate (Al (NO3) 3•9H2O) The atomic ratios of Zn and Al in the solution are 1:0.02, 1:0.03, 1:0.04, 1:0.05 and 1:0.06, respectively. The precursor solution is ultrasonically atomized and then transported to the nozzle under the action of O2 carrier gas to reach the heated silicon substrate to complete the atomization pyrolysis process. The parameters in the experiment are as follows: the carrier gas flow rate is 1.2L/min, the distance between the nozzle and the substrate is 4cm, the spray time is 5min, and the substrate temperature is 470℃. After the reaction is completed, the heater is turned off to allow the substrate to cool naturally before taking out the sample.

The CuInS2 film was prepared by an ultrasonic atomization pyrolysis sprayer: a glass substrate with a size of 25mm×25mm×1mm was used, and the substrate was ultrasonically cleaned in acetone, ethanol and deionized water before the film was deposited. The preparation of the precursor solution is as follows: deionized water is used as the solvent, copper chloride (CuCI:), indium chloride (InCl) and thiourea (sc(NH:)) are used as the raw materials of cu, In, and S, respectively. A certain concentration is prepared into a 100mL solution, and the In" concentration is 30mmol/L. The corresponding Cu:In:S atomic ratio in the solution is 1.25:1:6. Put the prepared solution into the 402 medical ultrasonic atomizer. The precursor liquid is atomized by the mechanical vibration of the piezoelectric atomizer. The droplets are sprayed on the substrate to form a film under the action of the transport gas. The air flow is about 2L /Min.

The ultrasonic atomization pyrolysis method is to dissolve the precursor in a suitable solvent to form a source solution. The source solution is ultrasonically atomized to produce fine droplets. The droplets are transported by the carrier gas to the reaction zone, and undergo evaporation, decomposition, homogenization or heterogeneous reaction to prepare the required film samples. The precursor solution is a mixed ethanol solution of zinc acetylacetonate (Zn(C;H,O2)2) and magnesium acetylacetonate (Mg(C;H,O2)2) with different substance ratios. A small amount of water is added to the solution as a source of oxygen in the film, and the addition of glacial acetic acid helps to dissolve zinc acetylacetonate and magnesium acetylacetonate in the ethanol solution. The atomization rate is controlled to be about 3mL/min by adjusting the carrier gas flow and atomization power. Using air as the carrier gas, the Mg.Zn1-xO film was successfully prepared by depositing on a quartz glass substrate at 300°C for 10 minutes.

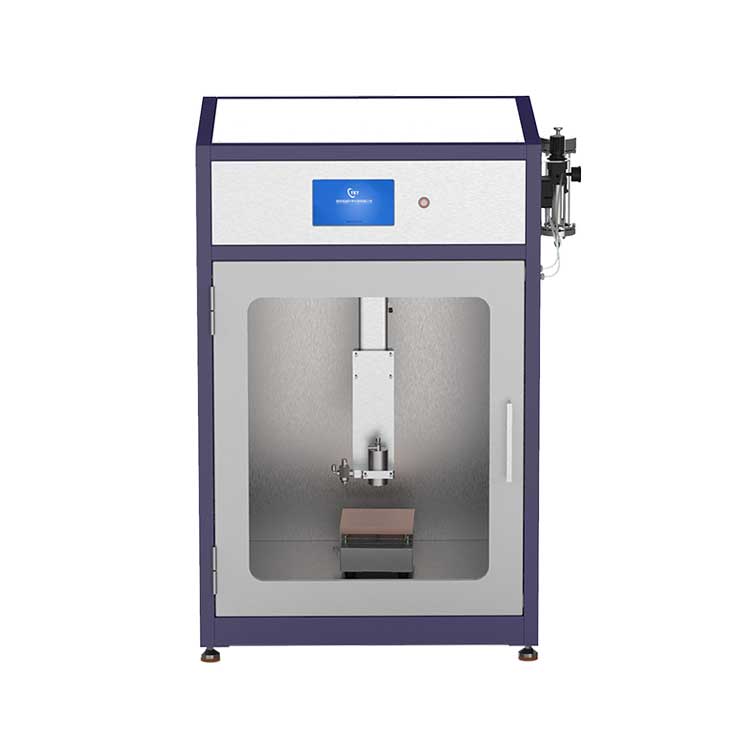

Prepare ATO film with ultrasonic atomization pyrolysis sprayer: prepare mother liquor, weigh pure Sn particles and Sb2O3 according to the molar ratio of Sn to Sb of 99:1, 96:4, 93:7, and 90:10, and then place it in concentrated hydrochloric acid and stir magnetically until the solution is transparent and clear. Adding an appropriate amount of absolute ethanol during the experiment can increase the amount of atomization; the preparation of the film In this experiment, a 30mm diameter quartz glass is used as the substrate(Quartz substrate can prevent the Na+ and K+ ions in ordinary glass from diffusing into the film at high temperature and affecting the photoelectric properties of the film). Before use, the substrate is ultrasonically oscillated with acetone for 20 minutes to remove oil, then cleaned with absolute ethanol, and dried for later use. The principle of the ultrasonic spray thermal decomposition method is shown in Figure 1. During the experiment, the mother liquor is placed in the container 1. Due to the high frequency ultrasonic oscillation of the container 2, the mother liquor is atomized into small droplets. Using argon as a carrier gas, small mist droplets are carried on the heated substrate to decompose and deposit, forming a uniform thin film. The exhaust gas produced by the reaction is discharged by the exhaust fan. In the experiment, the flow rate of the carrier gas, the ultrasonic frequency, and the distance between the spray port and the substrate have a great influence on the quality of the film. After experimental optimization, the carrier gas is argon, the volume flow is 500 mL/min, the ultrasonic oscillation frequency is 2000 kHz, and the distance between the spray port and the substrate is 5 mm.

Preparation of WO3 film with ultrasonic atomization pyrolysis sprayer: The preparation method of the film preparation precursor is to weigh 0.125g H2WO4 and place it in a beaker, add different amounts of 30% H2O2 solution and 100mL deionized water, in a water bath at 93°C Under the conditions of reaction for 1h, stir with a magnetic stirrer during the reaction to obtain a transparent and slightly blue liquid. Because the water evaporates during the reaction, the obtained liquid is added with deionized water to 200mL to obtain a concentration of 0.1005mol/L precursor fluid. Using a self-made ultrasonic spray thermal decomposition coating equipment [8], using high-purity nitrogen as the carrier gas, diluting the prepared precursor solution to different concentrations, and coating at a substrate temperature of 250 ℃, using ITO glass (7 Ω/ □, WL STNS12220, Shenzhen CSG), deposited in air atmosphere, spraying time is 20 ~ 80min. All samples studied in this paper (except the samples with different heat treatment temperatures) were heat-treated in air at 550℃ for 1h. After heat treatment, the film changed from white translucent to light yellow translucent. The sample name and its H2O2 addition amount and precursor concentration are shown in Table 1.

Copyright © Zhengzhou CY Scientific Instrument Co., Ltd. All Rights Reserved Update cookies preferences

| Sitemap | Technical Support: