The halogen lamp RTP annealing furnace is a 6-inch wafer rapid annealing furnace. It adopts innovative heating technology to realize real substrate temperature measurement. It does not need the temperature compensation of traditional rapid annealing furnaces. The temperature control is accurate and the temperature is highly repeatable. Customers include many international semiconductor companies and well-known scientific research teams. It is an ideal choice for semiconductor annealing process.

Technical features:

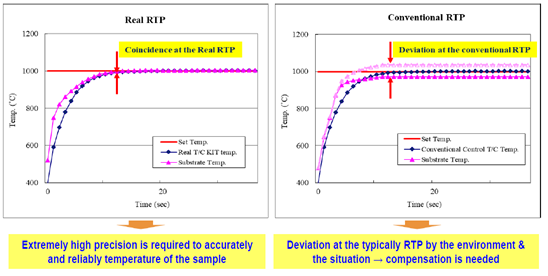

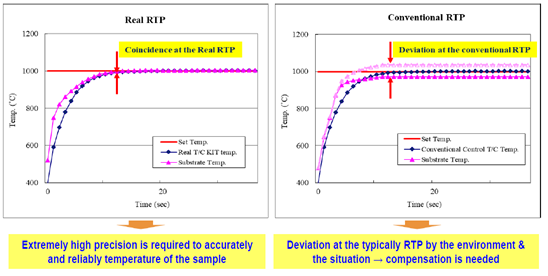

Real substrate temperature measurement without traditional temperature compensation

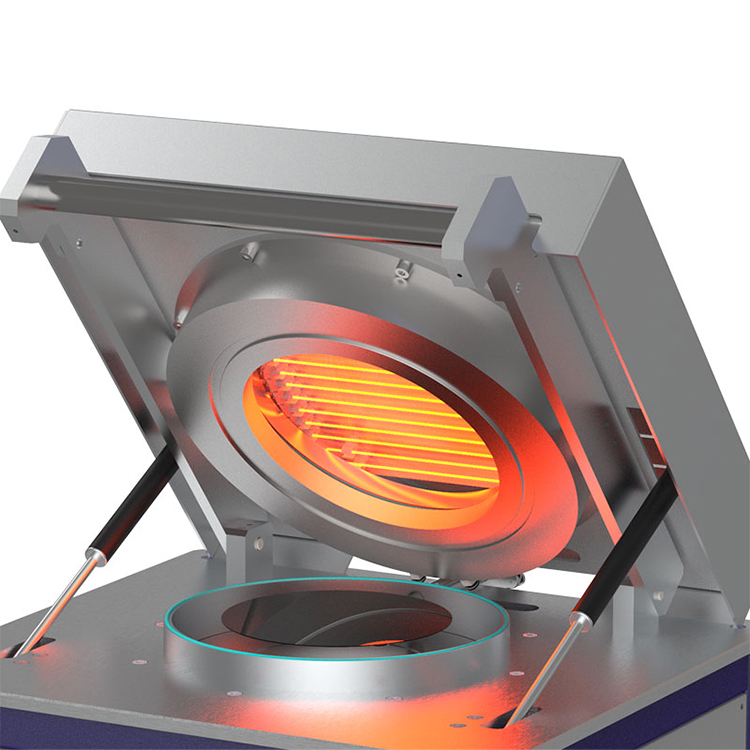

Infrared halogen tube lamp heating

Extremely excellent heating temperature accuracy and uniformity

Fast digital PID temperature control

Stainless steel cold wall vacuum chamber

Good system stability

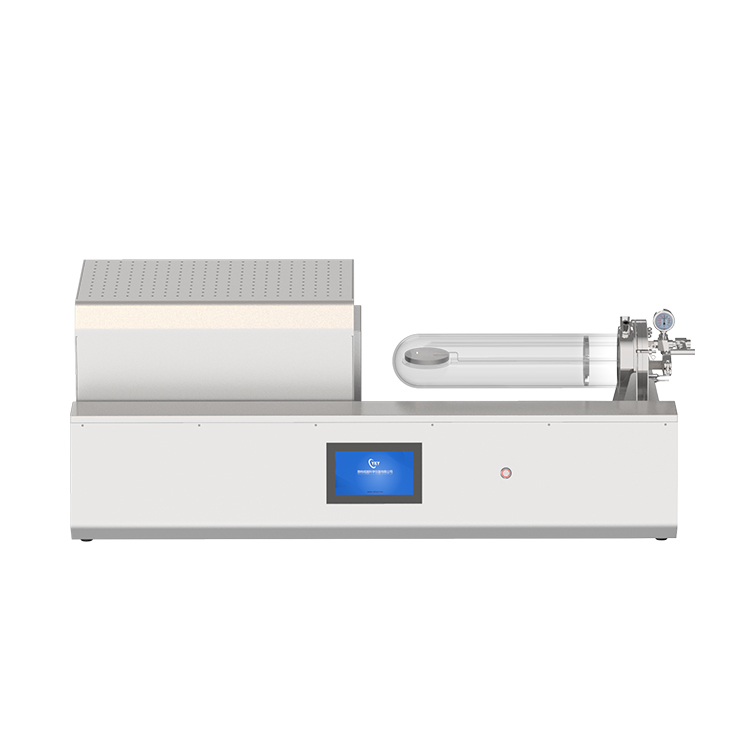

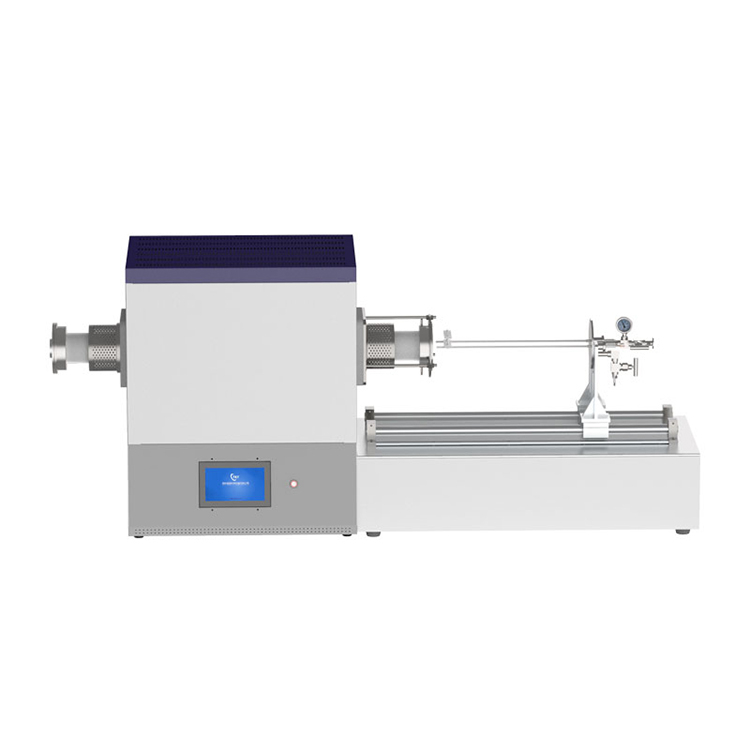

Compact structure, small desktop system

PC control with touch screen

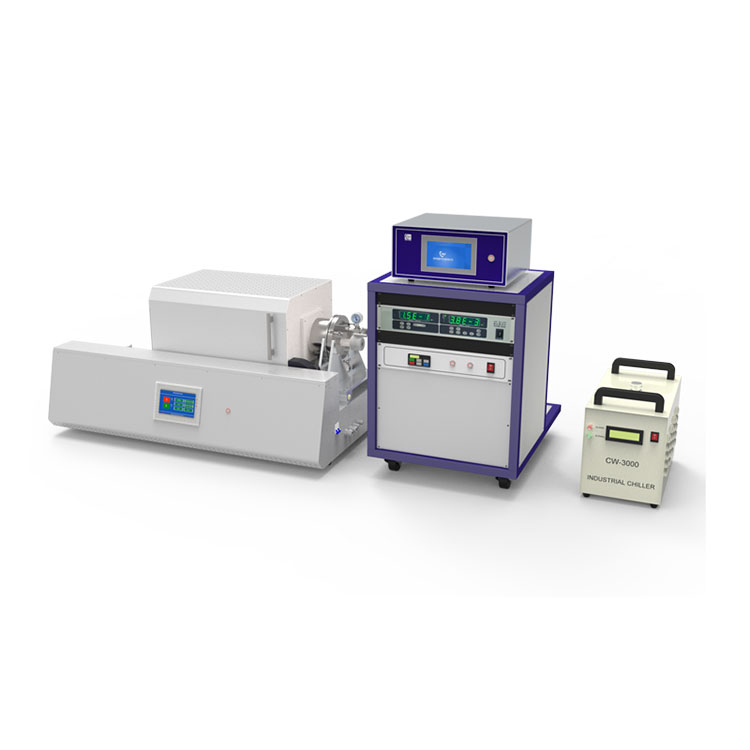

Compatible with normal pressure and vacuum environment, the standard value of vacuum degree is 5×10-3 Torr, and the vacuum degree is as low as 5×10-6 Torr using two-stage molecular pump

Up to 3-channel gases (MFC control)

No cross contamination, no metal contamination.

Introduction of real substrate temperature measurement technology:

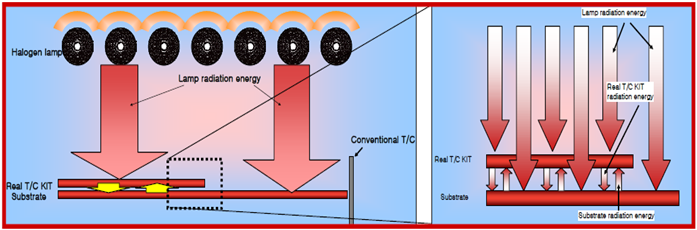

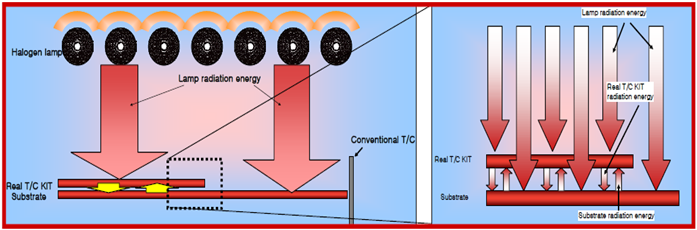

As shown in the figure above, the heat radiated by the array halogen lamp reaches the surface of the sample through the quartz window, and the sample is heated. The traditional rapid annealing furnace uses a thermocouple to measure the substrate temperature. Because the thermocouple is at a certain distance from the substrate, the measurement is not the substrate. The real temperature of the chip must be temperature compensated.

The halogen lamp RTP annealing furnace uses a dedicated flake-like Real T/C KIT for temperature measurement, as shown in the figure above, the contact thermometer is connected to the flake-like Real T/C KIT. The flake-like Real T/C KIT is located very close to the sample above when working, the array halogen lamp radiates heat to the sample surface through the quartz window, the sample is heated, and the flake-like Real T/C KIT is heated at the same time. Because the substrate is very close to the Real T/C KIT, there will be heat transfer between them, and the thermal equilibrium will be quickly reached, so the temperature measured by the flake-like Real T/C KIT is infinitely close to the real temperature of the substrate, thus realizing the real measurement of the substrate temperature.

Technical parameters:

Substrate size | 6 inches |

Substrate base | Quartz needle (optional SiC coated graphite base) |

Temperature range | 150-1250℃ |

Heating rate | 10-150℃/S |

Temperature uniformity | ≤±1.5% (@800℃, Silicon wafer) ≤±1.0% (@800℃, Substrate on SiC coated graphite susceptor) |

Temperature control accuracy | ≤ ±3℃ |

Temperature repeatability | ≤ ±3℃ |

Vacuum | 5.0E-3 Torr / 5.0E-6 Torr |

Gas supply | Standard 1 channel N2 purge and cooling gas circuit, controlled by MFC (up to 3 channels can be selected) |

Annealing duration | ≥35min@1250℃ |

Temperature control | Fast digital PID control |

Dimensions | 870mm*650mm*620mm |

Substrate type:

• Silicon wafers

• Compound semiconductor wafers

• GaN/Sapphire wafers for LEDs

• Silicon carbide wafers

• Poly silicon wafers for solar cells

• Glass substrates

• Metals

• Polymers

• Graphite and silicon carbide susceptors

Application areas:

Ion implantation/contact annealing, rapid thermal processing (RTP), rapid annealing (RTA), rapid thermal oxidation (RTO), rapid thermal nitridation (RTN), can be used in different environments such as vacuum, inert atmosphere, oxygen, hydrogen, mixed gas, etc. SiAu, SiAl, SiMo alloying, low dielectric materials, crystallization, densification, solar cell bonding, etc.