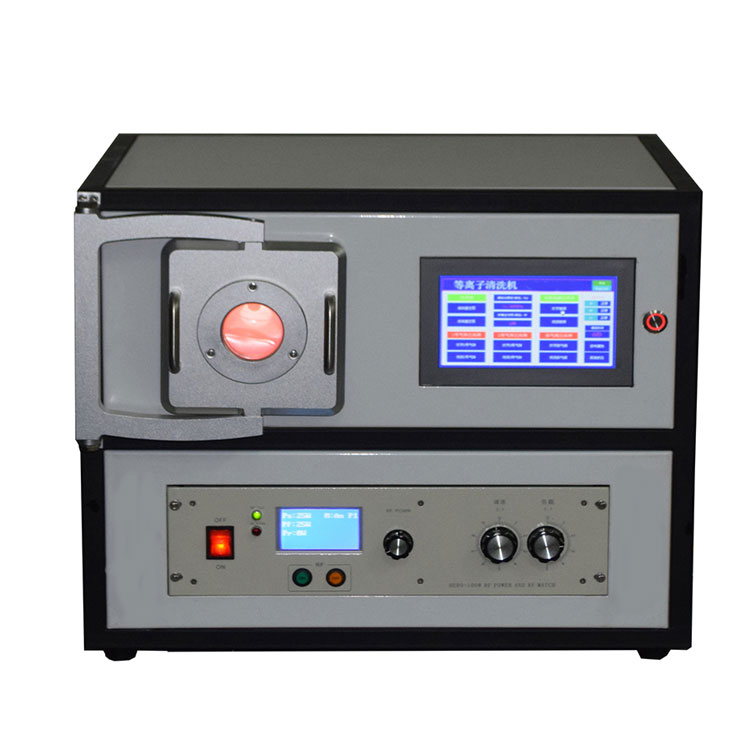

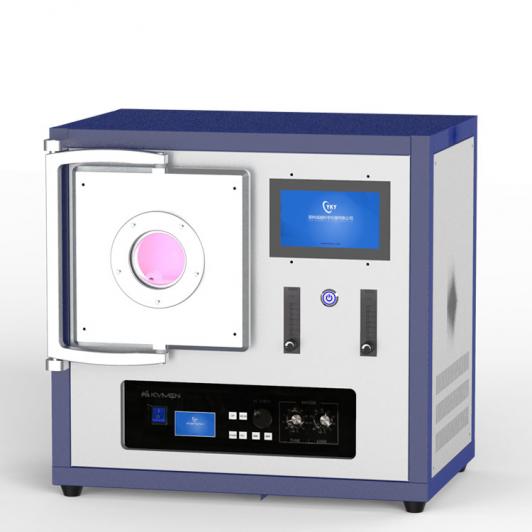

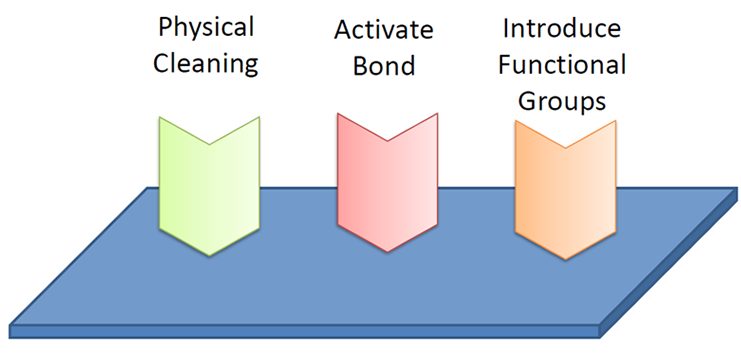

Vacuum plasma cleaner action principle:

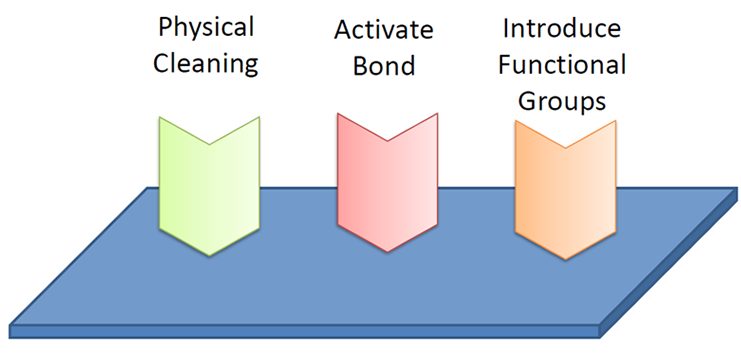

1.Etching on the surface of the material - physical effect

A large number of active particles in the plasma, such as a large number of ions, excited molecules, and free radicals, act on the surface of the solid sample, which not only removes the original contaminants and impurities, but also produces an etching effect to roughen the surface of the sample and form many fine pits, which increases the specific surface of the sample,improves the wetting properties of solid surfaces.

2.Activation bond energy, cross-linking

The energy of the particles in the plasma is between 0 and 20 eV, and most of the bond energy in the polymer are between 0 and 10 eV. Therefore, after the plasma acts on the solid surface, the original chemical bond on the solid surface can be broken. Free radicals in the plasma form a network of crosslinked structures with these bonds, greatly activating surface activity.

3.Formation of new functional groups - chemical action

If a reactive gas is introduced into the electric discharge gas, a complicated chemical reaction occurs on the surface of the activated material, and new functional groups such as hydrocarbonyl, amidogen, carboxyl group, and the like are introduced, and these functional groups are all active groups, which can significantly improve the surface activity of the material.

Vacuum plasma cleaner advantages:

(1) low processing temperature

The processing temperature can be as low as 80℃ and below 50 ℃. Low processing temperatures ensure no thermal effects on the sample surface.

(2) no pollution during the whole process

The plasma cleaner itself is a very environmentally friendly device that does not cause any pollution and does not cause any pollution during the treatment process.

(3) stable treatment effect

The treatment effect of plasma cleaning is very uniform and stable, and the conventional sample maintains good effect for a long time after treatment.

(4) It can handle samples of various shapes

For complex figurate samples, plasma cleaning can find the right solution.Vacuum plasma cleaning can clean the internal position of the solid sample.

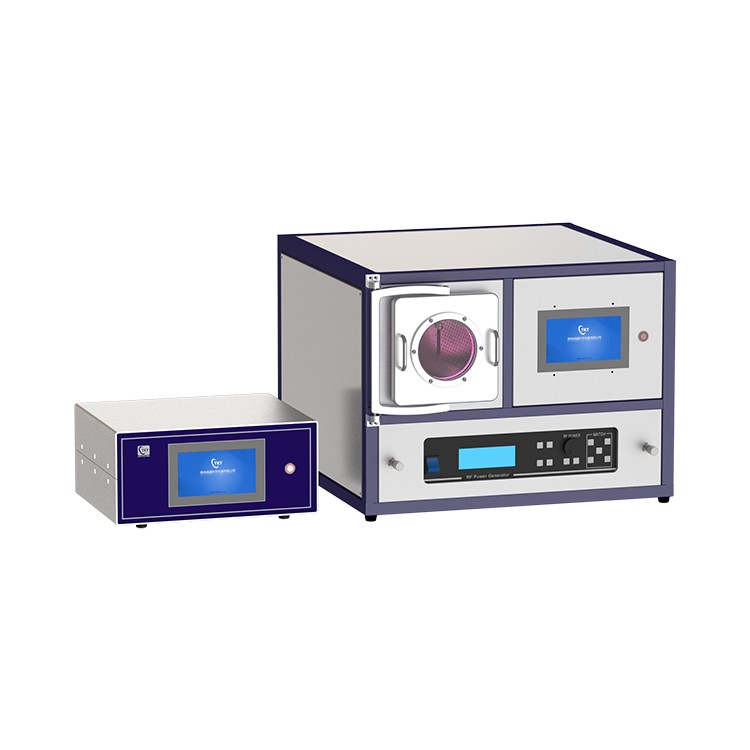

Vacuum plasma cleaner technical specifications:

System standard accessories |

Equipment size | 1105W * 1488D * 1842Hmm (2158mm with signal light height) |

Horizontal plate | 8layer |

battery lead plate | 402W * 450Dmm |

Gas flow controller | 2-circuit process gases, 0-300ml/min |

Vacuum measurement | Japanese ulvac vacuum gauge |

Human machine interface touch screen | SD independent research and development |

Electrode spacing | 48mm |

Signal indicator | 3 ribbon alert |

Vacuum pump | 90m3/h bipolar oil pump |

System Power & Machinery |

Power supply | AC380V, 50/60Hz . Rated power 5000W |

System weight (device host / vacuum pump) | <600Kg |

Equipment host size | 1805(W)×1988(D)×1842(H) mm |

RF power supply |

RF power frequency | 13.56MHz |

RF power supply | 1000W |

RF power matcher | Fully automatic matching, leading air capacitance technology |

Equipment necessary conditions |

Power supply | AC380V, 50/60Hz, three-phase five-wire , 7.5KVA |

Compressed air requirements | Anhydrous oil-free CDA 60~90psig |

Air draft system | ≥ 2 cubic / minute, the central exhaust gas treatment pipeline can be |

System ambient temperature requirements | ≤30℃(best room temperature) |

Process gas requirements | 15~20psig Purity 99.996% or above |