Plasma cleaning machine equipment principle:

1. Etching on the surface of the material - physical effect

A large number of active particles in the plasma, such as a large number of ions, excited molecules, and free radicals, act on the surface of the solid sample, which not only removes the original contaminants and impurities, but also produces an etching effect to roughen the surface of the sample and form many fine pits, which increases the specific surface of the sample,improves the wetting properties of solid surfaces.

2. activation bond energy, cross-linking

The energy of the particles in the plasma is between 0 and 20 eV, and most of the bond energy in the polymer are between 0 and 10 eV. Therefore, after the plasma acts on the solid surface, the original chemical bond on the solid surface can be broken. Free radicals in the plasma form a network of crosslinked structures with these bonds, greatly activating surface activity.

3. Formation of new functional groups - chemical action

If a reactive gas is introduced into the electric discharge gas, a complicated chemical reaction occurs on the surface of the activated material, and new functional groups such as hydrocarbonyl, amidogen, carboxyl group, and the like are introduced, and these functional groups are all active groups, which can significantly improve the surface activity of the material.

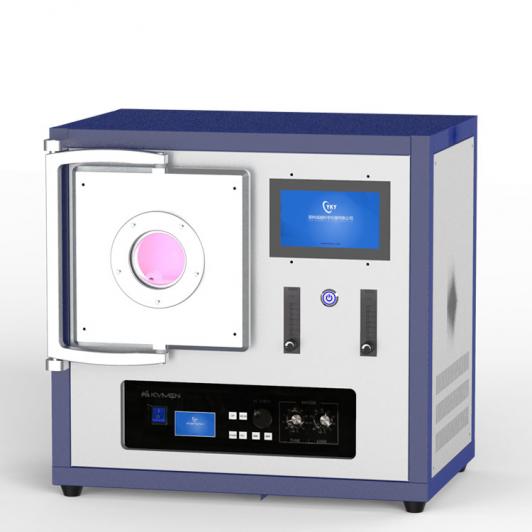

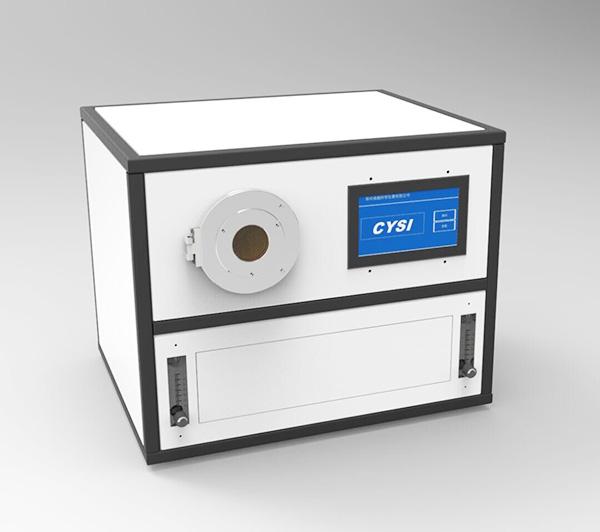

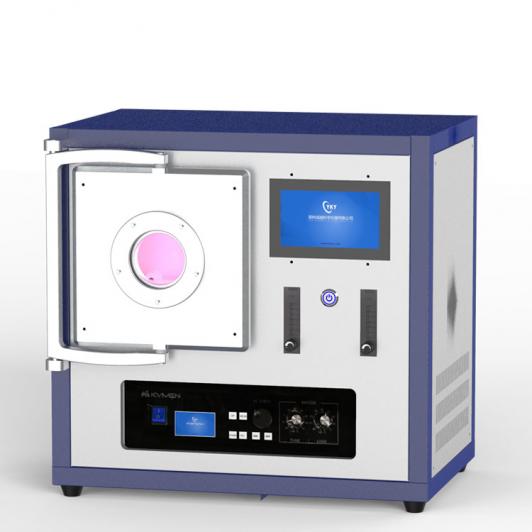

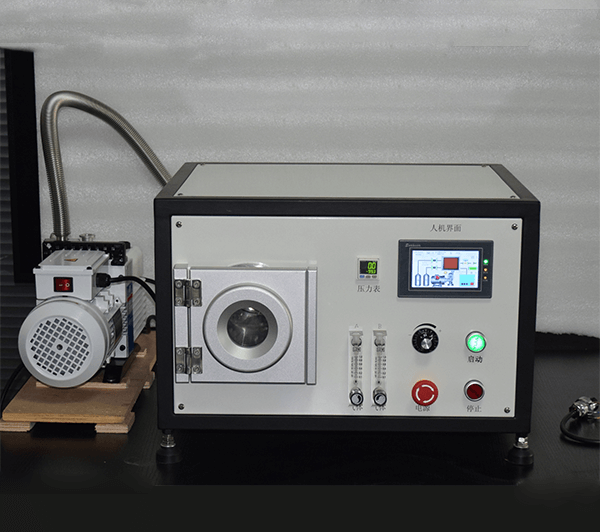

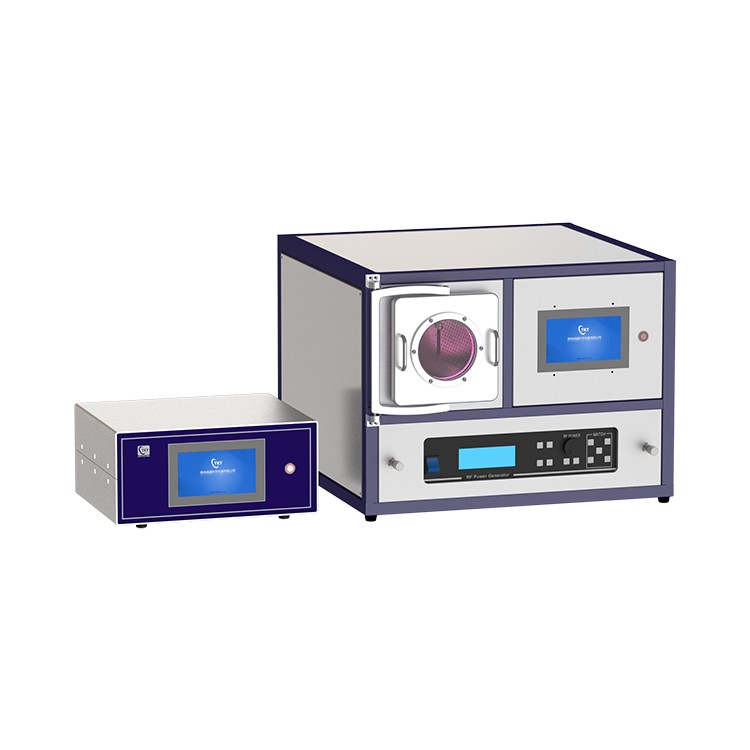

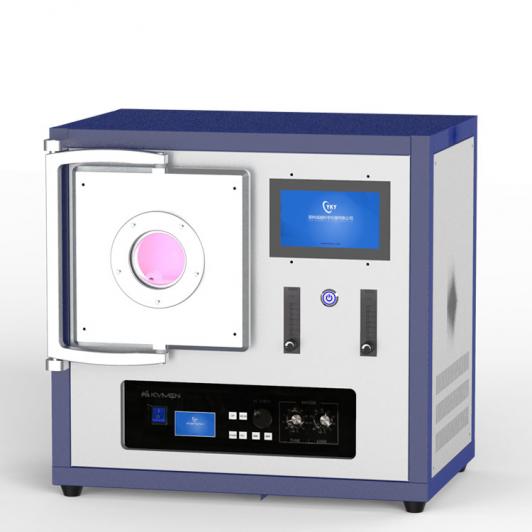

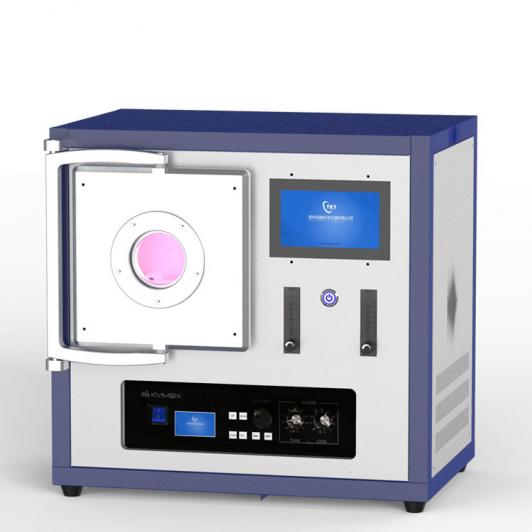

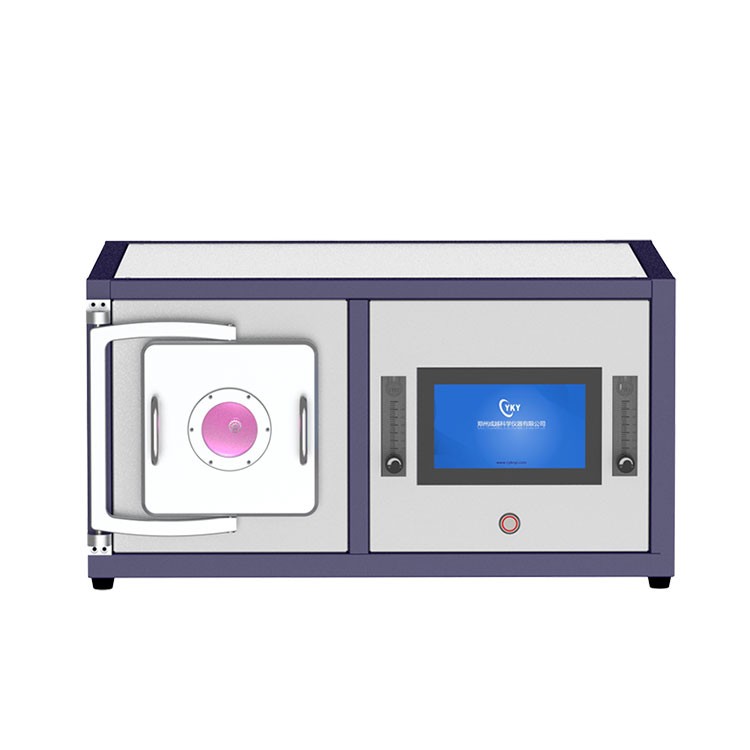

PCB board plasma cleaning machine technical parameters:

System standard accessories |

Equipment size | 1105W * 1488D * 1842Hmm (2158mm with signal light height) |

Horizontal plate | 8layer |

Electrode plate | 402W * 450Dmm |

Gas flow controller | 2 process gases ,0-300ml/min |

Vacuum measurement | Japanese ulvac vacuum gauge |

Human machine interface touch screen | SD independent research and development |

Electrode spacing | 48mm |

Signal indicator | 3 ibbon alert |

Vacuum pump | 90m3/h bipolar oil pump |

System Power & Machinery |

Power supply | AC380V, 50/60Hz ,Rated power 5000W |

System weight (device host / vacuum pump) | <600Kg |

Floor area: equipment host | 1805(W)×1988(D)×1842(H) mm |

RF power supply |

RF power frequency | 13.56MHz |

RF power supply | 1000W |

RF power matcher | Fully automatic matching, leading air capacitance technology |

Equipment prerequisites |

Power supply | AC380V, 50/60Hz, three-phase five-wire, 7.5KVA |

Compressed air requirements | Anhydrous oil-free CDA 60~90psig |

Exhaust system | ≥ 2 cubic / minute, the central exhaust gas treatment pipeline can be |

System ambient temperature requirements | ≤30℃(best room temperature) |

Process gas requirements | 15~20psig Purity 99.996% or above |

PCB board plasma cleaning machine application:

Plasma is used in a wide range of applications, from nuclear fusion to plasma TVs, from plasma film sputtering to industrial waste gas treatment, from plasma cutting to sterilization in biomedical applications.

What we are talking about now is the application of plasma surface modification, or plasma surface treatment. By using the high energy and unstable characteristics of the plasma. When the surface of the solid material contacts the plasma, the microstructure, chemical properties and energy of the surface will change.

Plasma surface modification (plasma surface treatment) is to use the characteristics of the plasma to clean, revitalite, and activate the surface of the solid material to be treated, thereby achieving the purpose of changing the surface microstructure, chemical properties, and energy.

The application of plasma cleaning has been very extensive, automotive manufacturing, mobile phone manufacturing, glass optics, materials science, electronic circuits, printing and paper, plastic film, packaging technology, medical and medical, textile industry, new energy technology, aerospace military, watch jewelry, etc.