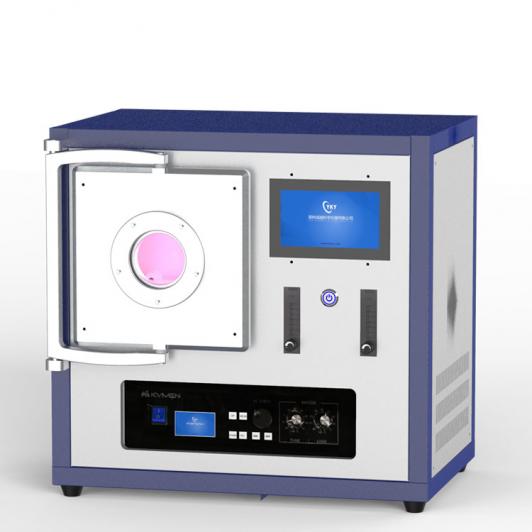

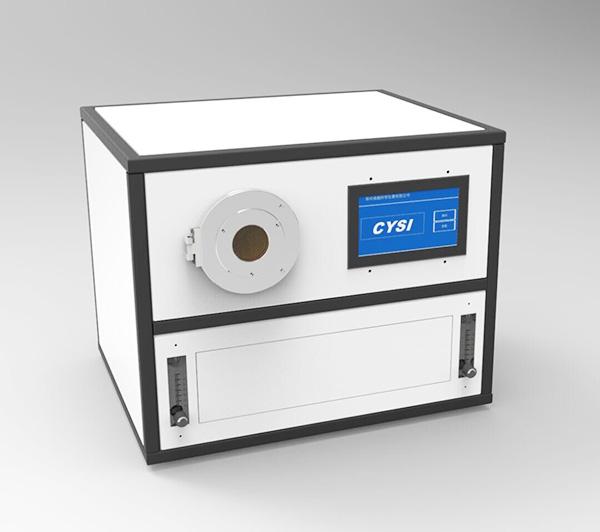

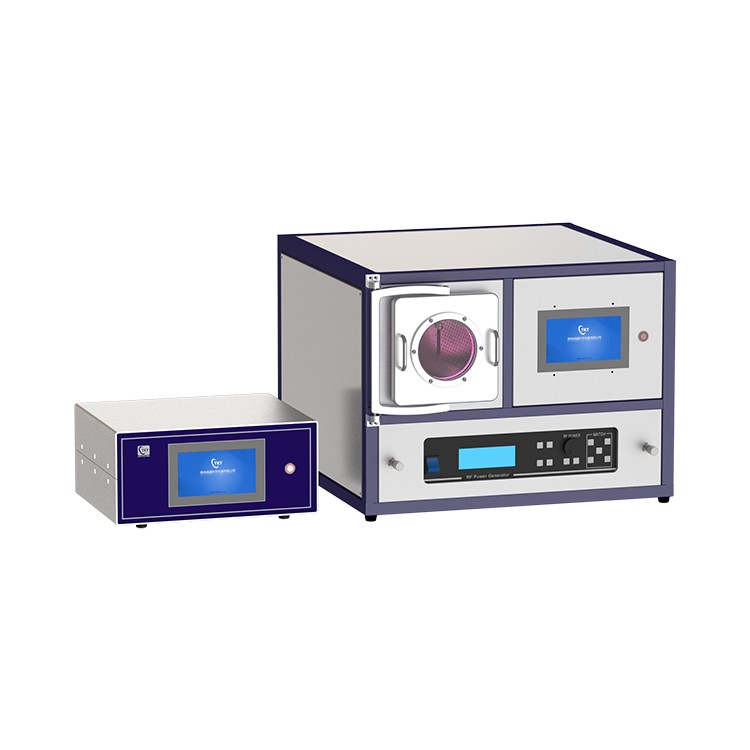

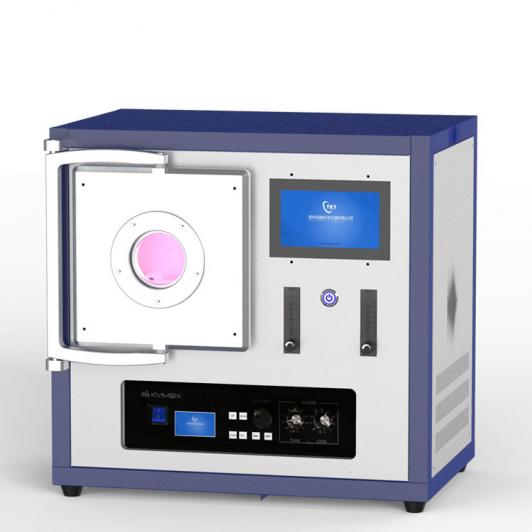

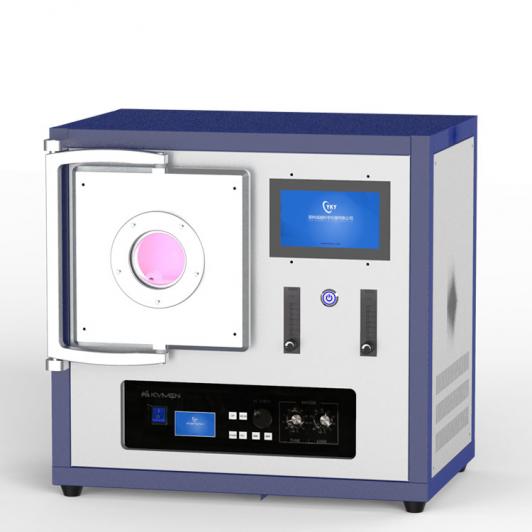

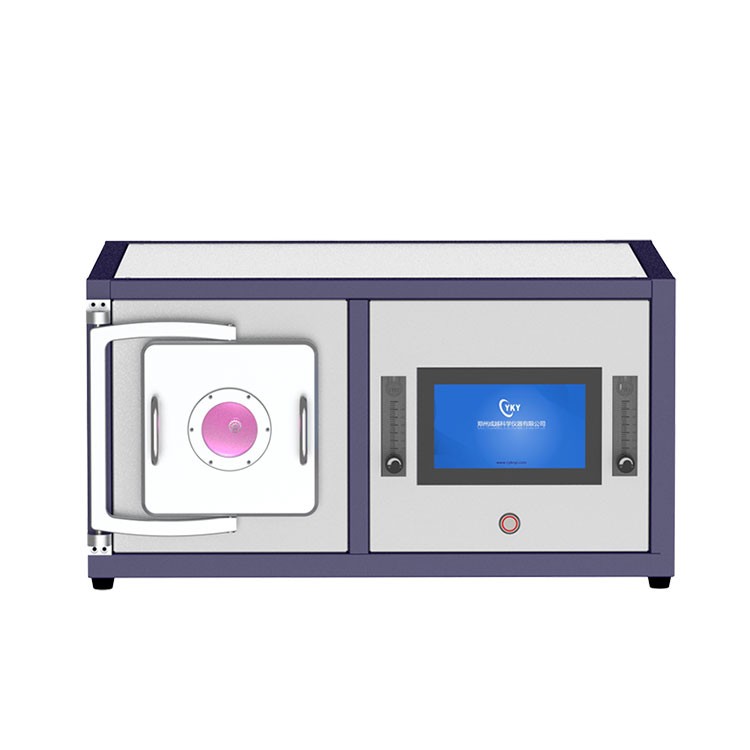

Plasma cleaner, also known as plasma surface treatment device, is a new high-tech technology that uses plasma to achieve the results that conventional cleaning methods cannot achieve. Plasma is a state of matter, also called the fourth state of matter, and does not belong to the common three-state of solid-liquid-gas. Applying enough energy to the gas to ionize it becomes a plasma state. The "active" components of the plasma include: ions, electrons, atoms, active groups, excited states of nuclides (metastasis), photons, and the like. Plasma cleaner is to treat the surface of the sample by utilizing the properties of these active components, thereby achieving the purpose of cleaning, coating, etc., improving the surface adhesion of the product, and facilitating the bonding, spraying, printing and sealing of the product.

70mm rotary spray gun plasma cleaner advantages:

(1) Low processing temperature

The processing temperature can be as low as 80℃ and below 50 ℃. Low processing temperatures ensure no thermal effects on the sample surface.

(2) No pollution during the whole process

The plasma cleaner itself is a very environmentally friendly device that does not cause any pollution and does not cause any pollution during the treatment process. It can be combined with the original production line to achieve fully automatic online production, saving labor costs.

(3) Stable treatment effect

The treatment effect of plasma cleaning is very uniform and stable, and the conventional sample maintains good effect for a long time after treatment.

70mm rotary spray gun plasma cleaner product principle:

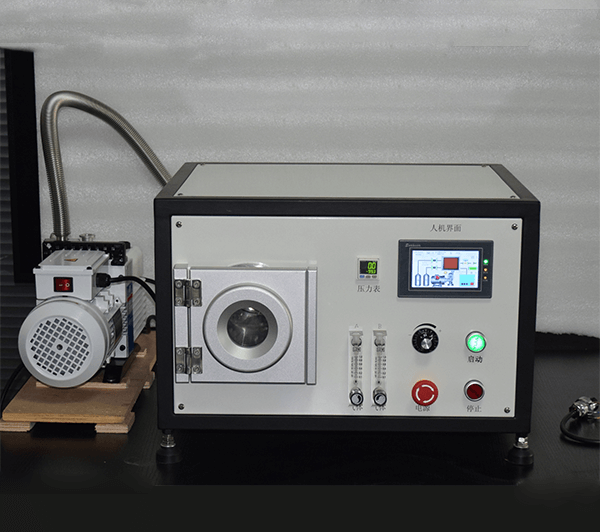

The structure of the plasma cleaner is mainly divided into three major components, namely high-voltage excitation power supply, plasma generator spray gun, and control system.

(A) High-voltage excitation power supply:

The generation of plasma requires high-voltage excitation, and the atmospheric low-temperature plasma is excited by an intermediate frequency power supply at a frequency of 10-40 kHz. The high voltage is at 4-10KV. The parameters can be adjusted according to the actual conditions of the sample, and the optimal modification effect has been achieved.

(B) Plasma generator spray gun:

The atmospheric low-temperature plasma generator spray gun can be divided into two types: jet flow direct injection and rotary direct injection, the difference is that the treatment area is different.

(C) Control system:

The control system functions is to control the operation of the entire atmospheric low temperature plasma cleaning equipment and the protection of the overall system.

70mm rotary spray gun plasma cleaner technical specifications:

System standard accessories |

Equipment size | 160W * 500D * 400Hmm |

weight | 20KG |

Input power | 220V,50/60Hz |

power | 1000W adjustable |

High voltage frequency | 10-40KHz |

Protection | Overload protection, short circuit protection, open circuit protection, temperature protection |

remote control | Local control and remote control are available |

Spray gun selection |

Direct spray gun | 2mm, 5mm |

Magnetic suspension rotary motor spray gun | 50mm, 70mm |