On the afternoon of May 10th, Turkish customers came to our company to conduct a test of the hot isostatic pressing furnace.

The Hot Isostatic Pressing (HIP) process is a method in which the inert gases such as nitrogen or argon is used as a pressure transmitting medium, and the product is placed in a closed container, Under the combined action of temperature of 900℃~2000℃and pressure of 100~200MPa, the same pressure is applied to the product, and the product is pressed and sintered. Under the combined action of high temperature and high pressure, components or parts are heated in an inert gas, generally argon, which applies "isostatic" pressure uniformly in all directions. Therefore, the processed product has high density, uniformity and excellent performance. At the same time, the technology has the characteristics of short production cycle, low process, low energy consumption and small material loss.

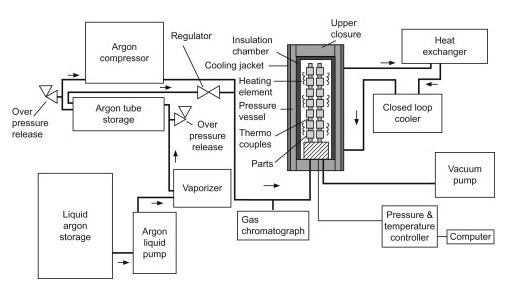

The hot isostatic pressing device consists of high pressure vessel, heating furnace, compressor, vacuum pump, gas storage tank, cooling system, and computer control system, wherein the high pressure vessel is a key device of the entire equipment. the schematic diagram of hot isostatic pressing is shown in Fig. 1.

FIG.1 Schematic diagram of hot isostatic pressing

Hot isostatic pressing technology is widely used in nuclear materials, aerospace materials, hard alloys, high-temperature alloys and ceramic materials. It is an advanced production process and means for developing and processing materials and improving material properties. A practical technology in the production of high-performance materials is also a new technology indispensable for the development of new materials.

Our company's hot isostatic pressing furnace can be customized according to customer requirements, fully satisfying the needs of customers. The hot isostatic pressing furnace chamber is made of SS304 stainless steel, and a safety valve is installed on the chamber. When the pressure of the chamber exceeds the maximum value, the safety valve will automatically release pressure; the stainless steel chamber is equipped with an explosion-proof box; the device is equipped with a moving wheel to move easily; the molybdenum wire is used as the heating element, and molybdenum reflection plate is installed outside the device, and the maximum temperature can reach 1300℃. Through the testing of the hot isostatic pressing furnace, the Turkish customers expressed their affirmation to our company's customized hot isostatic pressing furnace.

FIG.2 Equipment test

Copyright © Zhengzhou CY Scientific Instrument Co., Ltd. All Rights Reserved Update cookies preferences

| Sitemap | Technical Support: