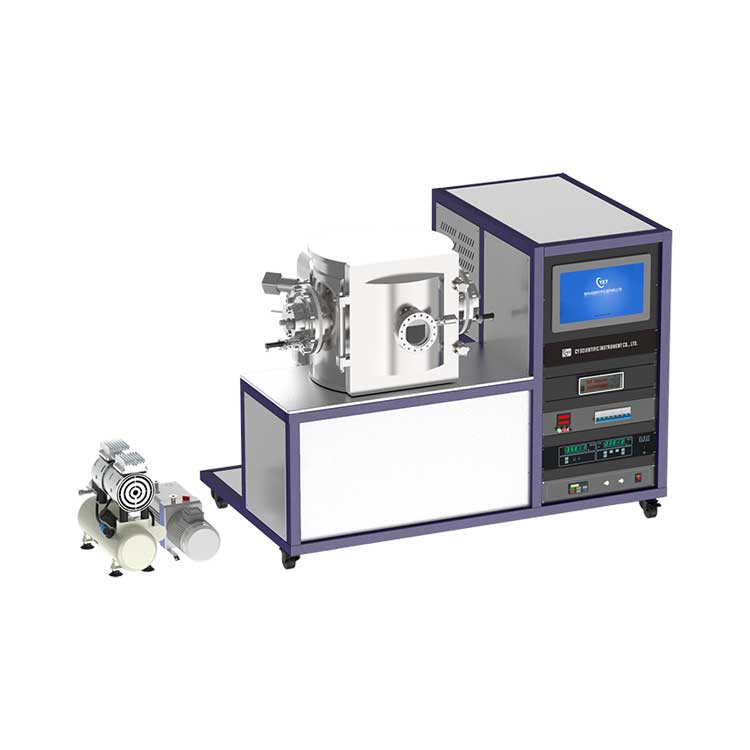

The electron beam evaporation coating equipment is mainly used to prepare various conductive films, semiconductor films, ferroelectric films, optical films, micro-nano device micro-processing, electron microscope sample pretreatment, etc. It is especially suitable for vapor deposition of various refractory metal materials. It can be used not only for hard substrates such as glass and silicon wafers, but also for coating on flexible substrates such as PDMS, PTFE, and PI.

Technical parameters:

Operating conditions | Ambient temperature | 5℃~40℃ |

Power supply | 380V |

Power | ≤20KW |

Water pressure | ≤2.5bar |

Vacuum chamber size | Evaporation chamber size | φ500×H500(mm) |

transition warehouse | φ280×H300(mm) |

Electron gun | 1 set of new electron gun, 6-hole crucible |

Ion source | 1 set of Kaufman ion source K08 |

Sample turntable | Sample size: ≤φ150mm, the sample can be rotated, and the distance between the sample and the electron gun can be adjusted up and down (the shape of the sample holder is designed according to user requirements), the heating temperature is ≤500℃ |

System vacuum | Ultimate vacuum | after 12-24 hours of baking, continuous pumping gas≤5x10-5Pa |

Ultimate vacuum | Pumping rate: Vacuum degree≤5x10-4Pa within 40 minutes from atmospheric pressure |

Leakage rate of the system | Leakage rate of the system: the leakage rate of the whole machine is less than or equal to1×10-8Pa.L/s, After stopping the pump for 12 hours, measuring the vacuum degree of the vacuum chamber less than or equal to 10Pa. |

Vacuum pumping system | TM160 film thickness meter is used for monitoring. |

Coating monitoring | TM160 film thickness meter is used for monitoring |

The unevenness of the coating thickness | ≤3% |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.