| Working Voltage | 220V 50/60Hz, Single Phase (110V AC is available at extra cost) |

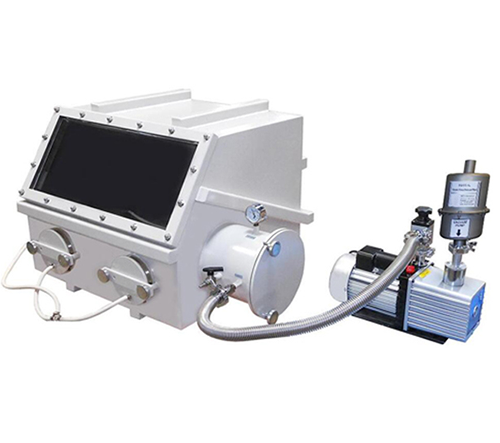

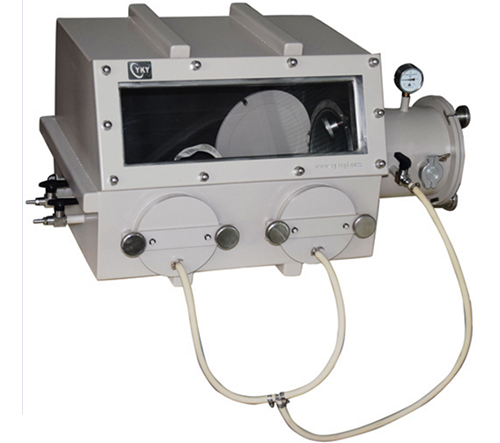

Glove Box Chamber

| Case Material: Made of 11 gauge (3mm thickness) 304 stainless steel sheet which provide heavy duty structure for vacuum

Dimensions: 1120mm(L) x 740mm(W) x 900mm(H)

Max. Positive Pressure: 810 Torr (1.1 atm)

Max. Vacuum Level: 0.5 Torr (by mechanical pump) |

| Air-lock Chamber with Air lift | Dimensions: 360mm(ID) x 435mm(L)

Max. Vacuum Level: 0.05 Torr |

| Transparent Front Panel | Dimension: 1040mm(L) x 405mm(W)

Removable for putting in devices |

Gloves

| Glove Port size: 190mm(Dia.)

8'' Butadyl® Gloves included (with increased stretching, bending ability and tear strength, and offer strong resistance to aromatics, hydrocarbons, solvents, fats, and acids)

Clamps and sealing flanges included |

| Vacuum Gauge and Valves | One vacuum gauge is installed on airlock chamber.

1 barbed needle valve and 1 KF-25 Vacuum port on the airlock chamber.

1 KF40 port and 2 1/2" barbed needle valves are built on the side of the main chamber.

2 KF25 ports on the back of glove box chamber.

3 KF40 ports on the back of glove box chamber for connecting to gas purification system. |

Purification System

| Automatic moisture removal <2 ppm, which is Dew Point < -71.7°C (<11 ppm H2 is usually needed for Li-Ion battery assembly) -- click to see Conversion of moisture/humidity

Precision Humidity Analyzer with KF25 Flange (0-999 ppm) is installed on the Purification System with accuracy +/-0.1ppm

Large capacity moisture filtration is built-in the bottom of the mobile cart, which can absorb H2 upto 1.5kg

Regeneration process control can automatically regenerate filter when it is saturated

Automatic pressure control system is able to maintain the pressure at a constant level

6" color PLC touch panel allow the user to set and read the humidity and pressure level easily.

The control panel is removable, which can be placed anywhere for easy operation. |

| Purification Pipeline | 304 stainless steel, KF40 port |

Vacuum pump

| Heavy duty vacuum pump with filter is included for initial pump down and purging if needed

Stainless steel vacuum bellow and valve are included |

| Gas Requirement | Working gasses: Atmospheric Gases, N2, Argon

Regeneration Gas: N2

One float meter built in bottom of mobile cart for accurate gas filling |

| Leakage Rate in Glove Box Chamber | < 3 Torr/hour |

| Power Extension | One extension socket (Max power 1500W) is installed in the glove box main chamber |

| Warranty | One-year limited warranty with lifetime support |