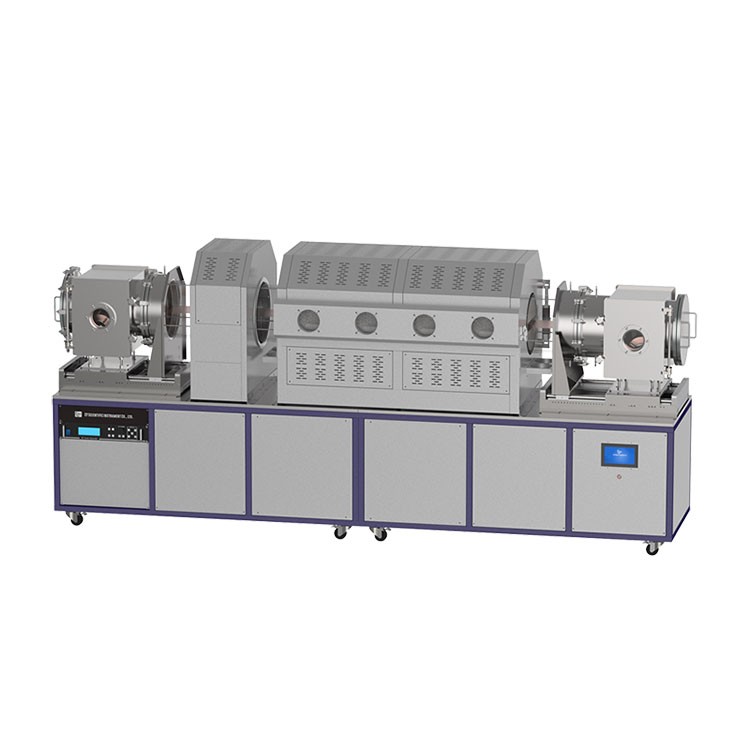

1500℃ single heating zone high vacuum CVD system consists of a 1500℃ single temperature zone tube furnace, a three-channel float flowmeter and a high vacuum molecular pump set. The tube furnace is controlled by the precision temperature control instrument for PID temperature control. It can edit the 30-segment temperature rise and fall program and has the function of overheating and short circuit protection. The flanges on both sides of the furnace tube are equipped with a digital vacuum gauge and a mechanical pressure gauge, which can be used to control the atmosphere in the furnace tube. At the same time, the tube furnace is operated by high-definition true color touch screen, which is easy to use. Even non-professionals can master the use of the instrument after simple training, which can greatly improve your experiment efficiency.

The furnace tube is made of high-purity alumina, and the furnace body adopts integrated design. The unique design can ensure the system is stable and safe at 1500℃. The heating element is made of high-quality silicon carbon rod, which can reach 1500℃ high temperature. If the customer has the need, the silicon molybdenum rod heating element can be customized to achieve a higher temperature of 1700℃.

The system is also equipped with a precision molecular pump set, which can achieve a vacuum of 1.0E-3pa level, which can provide users with a purer and more stringent experimental environment than ordinary mechanical pumps.

1500℃ single heating zone high vacuum CVD system applications:

It is suitable for high-temperature sintering, metal annealing, quality inspection, etc. in universities, research institutes, industrial and mining enterprises, especially for CVD experiments that require a variety of gas mixing atmospheres.

1500℃ single heating zone high vacuum CVD system technical parameters:

Vacuum tube furnace | Model | CY-O1500-60IT |

Tube material | High purity alumina |

Tube diameter | 60mm (optional 50mm, 80mm, 100mm) |

Tube length | 1000mm |

Furnace chamber length | 400mm |

Heating zone length | 300mm |

Constant temperature zone | 150mm |

Operating temperature | ≤1450℃ |

Temperature control accuracy | ±1℃ |

Temperature control mode | 30 or 50 segment program temperature control |

Display mode | LCD |

Sealing method | 304 stainless steel vacuum flange |

Flange interface | 1/4" ferrule connector, KF16/25/40 joint |

Vacuum | 4.4E-3Pa |

Power supply | AC:220V 50/60Hz |

Gas supply system | Model | CY-3Z |

Gas channel | 3-channel |

Measuring unit | Gas mass flow meter |

Measuring range | A channel: 0~100SCCM H2 gas | Remarks: If you need other ranges or gas types, you need to specify when ordering. According to the customer's specific requirements, the flow meter of the corresponding gas type and range can be selected. |

B channel: 0~300SCCM N2 gas |

C channel: 0~500SCCM Ar gas |

measurement accuracy | ±1.0%F.S |

Pipe pressure resistance | 0.03MPa |

Working pressure difference | 50~300KPa |

Connecting pipe | 304 stainless steel |

Gas channel | 304 stainless steel needle valve |

Interface specification | 1/4" ferrule connector for gas inlet and outlet |

Exhaust system | Model | CY-GZK103-A |

Molecular pump | CY-600 |

Backing pump | Rotary vane pump |

Pumping rate | Molecular pump: 600L/S | Comprehensive gas pumping performance: 30 minutes vacuum can reach: 1.0E-3Pa |

Rotary vane pump: 1.1L/S |

Pumping interface | KF40 |

Exhaust interface | KF16 |

Vacuum measurement | Compound vacuum gauge: Resistance gauge + ionization gauge |

Ultimate vacuum | 1.0E-5Pa |

Power supply | AC:220V 50/60Hz |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.