Plasma -enhanced chemical vapor deposition (PECVD) is a type of chemical vapor deposition characterized by the use of plasma activation at low temperatures to enhance the chemical vapor deposition reaction. The advantages of this method are that the deposition temperature is low, the deposition rate is fast, and the film produced has excellent electrical properties, good substrate adhesion and excellent step coverage.

PECVD vapor deposition application areas:

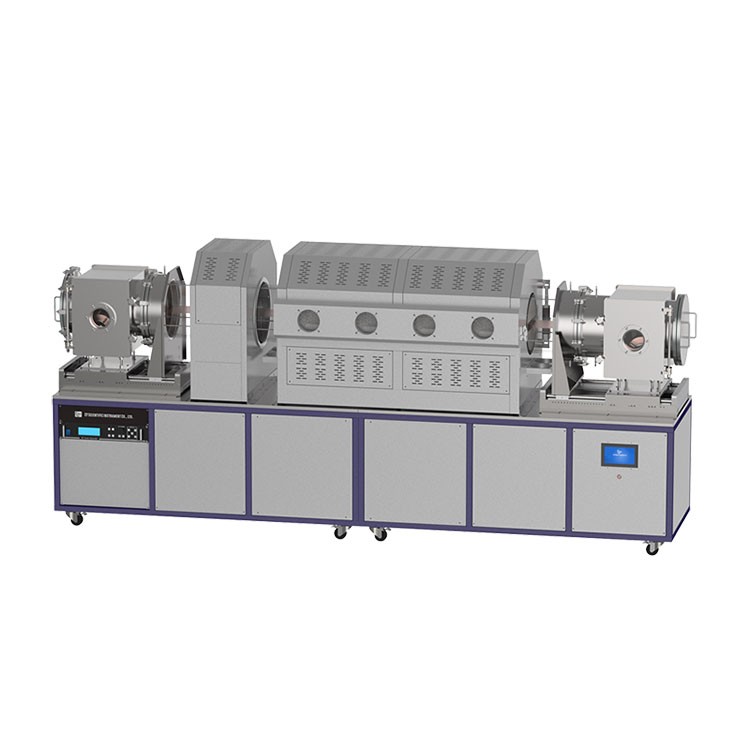

Plasma enhanced CVD systems can be used in: graphene preparation, sulfide preparation, nanomaterials preparation and other test sites. A variety of films such as SiOx, SiNx, amorphous silicon, microcrystalline silicon, nano -silicon, SiC, diamond-like, etc. can be deposited on the surface of flake or similar shape samples, and P -type and N-type doped films can be deposited. The deposited film has good uniformity, compactness, adhesion and insulation. Widely used in cutting tools, high-precision molds, hard coatings, high-end decoration and other fields, PECVD vapor deposition has a wide range of applications in ultra -large scale integrated circuits, optoelectronic devices, MEMS and other fields.

Technical parameters:

| Model number | CY-PECVD-200SST |

| Cavity size | Phi 500 - |

| Warm zone length | 200 |

| Rf power supply | 500W- |

| Temperature | 1000 ℃ |

| Pump for forestage | Molecular pump set |

| Display type | T |

| Warm zone | I- |

| Water cooler | CW5200 |

| Cavity material | SS |

| Sample heating Heating temperature | Above RT-1000℃, temperature control accuracy: ±1。C, using temperature control meter for temperature control; Adjustable speed: 1-20rpm adjustable |

| Spray head size | Φ90mm, the electrode spacing between the spray head and the sample 40-100mm online continuous adjustable (can be adjusted according to the process), and with a ruler index display |

| Sample Table | 200mm diameter |

| Working vacuum for deposition | 0.133-133Pa (can be adjusted according to process) |

| Top flange | It can be lifted by motor, the substrate is easy to change, and there is a visual port |

Substrate Table | Linear and azimuth motion of the substrate table, substrate heating and temperature control, mounting table and touch screen control, substrate linear motion is manually controlled, and substrate rotation is controlled by DC motors |

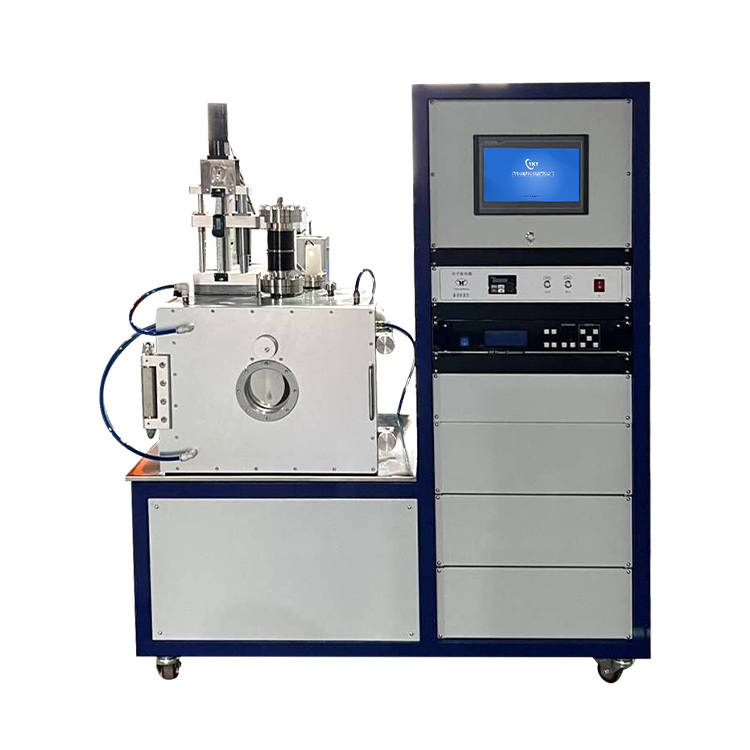

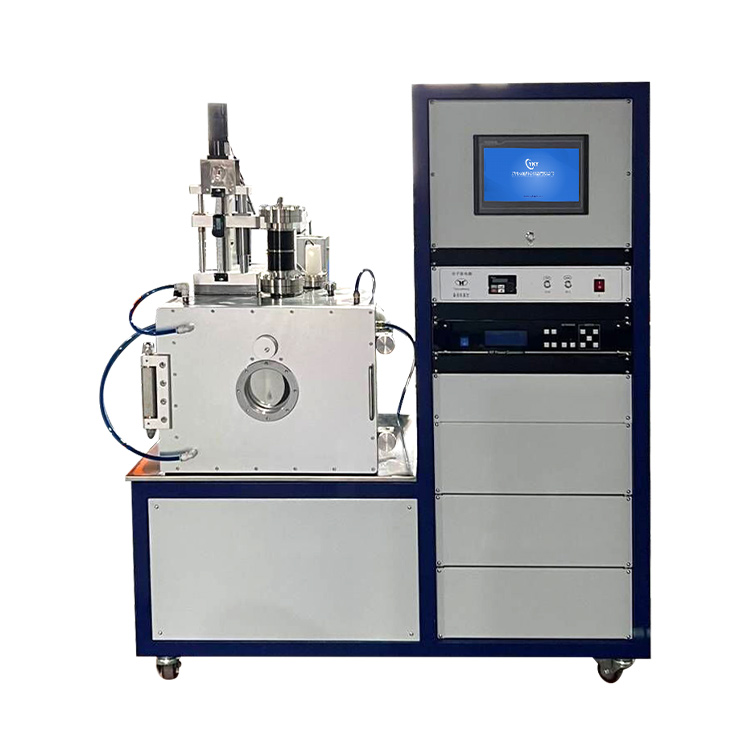

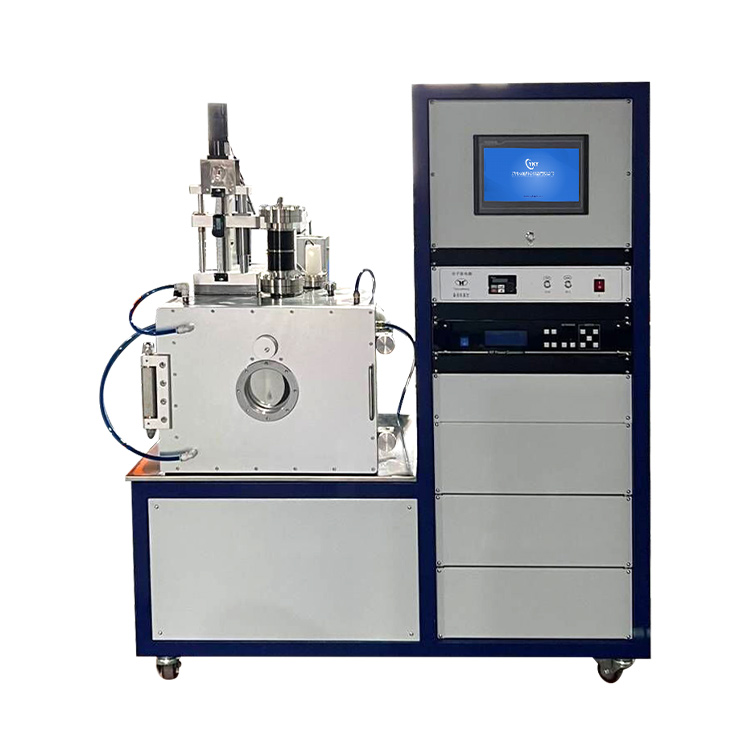

Vacuum chamber | Front door opening type, φ500mm X 500mm stainless steel |

Observation window | φ100mm with baffle |

Mass flowmeter | Six way mass flow meter |

Number paths of gas | Six paths |

Pressure range | 0.15 Mpa to 0.15 Mpa |

Range | 0 to 100 SCCM (oxygen) 0 to 100 SCCM (CF4) 0 to 200 SCCM (SF6) 0 to 200 SCCM (argon) 0 to 500 SCCM (other gases air) 0-500 SCCM (other gases nitrogen) |

Flow control range | Plus or minus 1.5% |

Gas path material | 304 stainless steel |

Pipe joint | 6.35mm bushing joint |

Vacuum system | Front pump: oil-free vacuum pump 4.7L/S Molecular pump: 1200L/S |

Measuring range | 1 x 10-5 to 1 x 105Pa |

Measurement accuracy | 1 x 10-5 ~ 1 x 10-4Pa±40% reading 1 x 10-4 ~ 1 x 105Pa for a reading of ±20% |