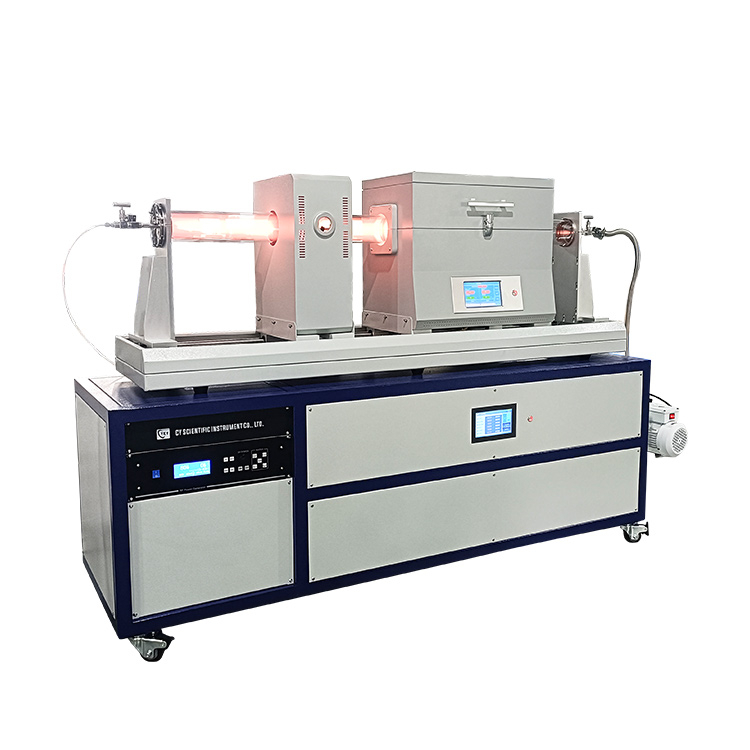

CVD vapor deposition system for including metal films

CVD vapor deposition systems are widely used in materials science and engineering for the preparation of various functional thin films, including metal films, oxide films, nitride films, carbon nanotubes, etc. They have important applications in semiconductor, optoelectronics, energy, biomedical, and other fields

CVD (Chemical Vapor Deposition) is a commonly used thin film deposition technique, which involves the reaction of gas-phase reactants with a substrate surface at high temperatures to form a thin film. Here are some common technical parameters of a CVD system:1. Reaction chamber temperature: Typically ranging from a few hundred to a few thousand degrees Celsius, depending on the desired reaction temperature and material.

2. Reaction gases: Different reaction gases can be used depending on the desired thin film material and structure, such as ammonia, hydrogen, oxygen, silicon dioxide, etc.

3. Pressure range: Typically ranging from a few hundred to a few thousand pascals, depending on the reactants and reaction conditions.

4. Reaction time: The reaction time can vary from a few minutes to several hours, depending on the desired thin film thickness and quality.

5. Substrate material: CVD systems can be used with various substrate materials, such as silicon, glass, metals, etc.

6. Application fields: CVD vapor deposition systems are widely used in materials science and engineering for the preparation of various functional thin films, including metal films, oxide films, nitride films, carbon nanotubes, etc. They have important applications in semiconductor, optoelectronics, energy, biomedical, and other fields.

Technical parameters

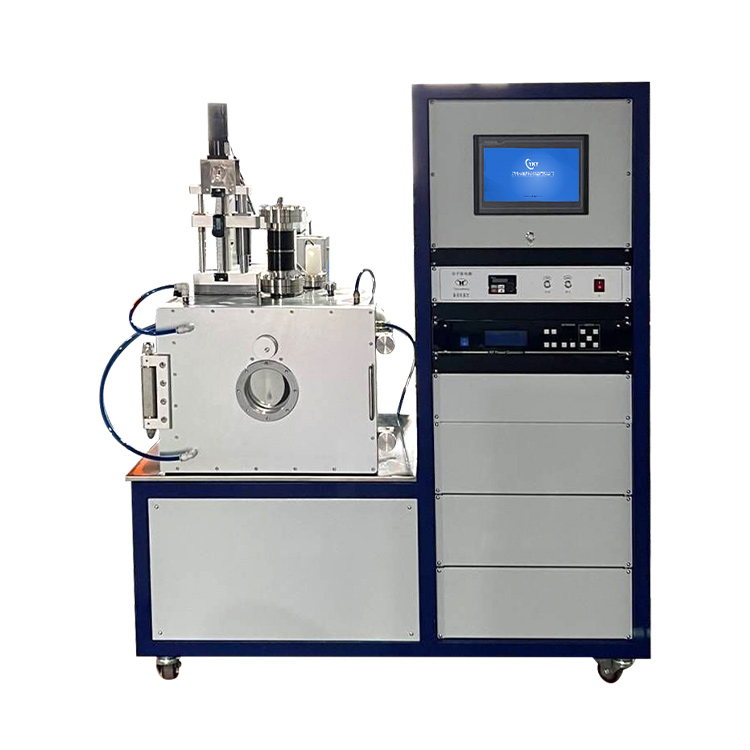

RF power supply | Signal frequency | 13.56MHz±0.005% |

Power output range | 0~300W |

Maximum reflected power | 100W |

Reflected power (at maximum power) | <3W |

Power stability | ±0.1% |

Tube furnace | Tube material | High purity quartz |

Outer diameter of tube | 100mm |

Tube length | 1200mm |

Furnace chamber length | 440mm |

Heating zone length | 200mm+200mm (two temperature zone) |

Constant temperature zone length | 200mm |

Continuous working temperature | Max.1100℃ |

Temperature control accuracy | ±1℃ |

Temperature control mode | 30 segment program temperature control |

Display mode | LCD |

Sealing method | 304 stainless steel vacuum flange |

Gas supply system | Model | CY-6Z |

Channel numbers | 6 |

Measuring unit | Mass flow controller |

Measuring range | A channel: 0~200SCCM for H2 | Remarks: If other ranges are required, please specify when ordering. According to the customer's specific requirements, the flow meter of corresponding gas type and range is optional. |

B channel: 0~200SCCM for CH4 |

C channel: 0~200SCCM for C2H4 |

C channel: 0~500SCCM for N2 |

D channel: 0~500SCCM for NH3 |

E channel: 0~500SCCM for Ar |

Measurement accuracy | ±1.5%F.S |

Working pressure difference | -0.15Mpa~0.15Mpa |

Connecting pipe | 304 stainless steel |

Gas channel | 304 stainless steel needle valve |

Interface specification | 1/4" ferrule connector for gas inlet and outlet |

Vacuum system | Mechanical pump | Double-stage rotary vane pump |

Pumping rate | 1.1L/S |

Vacuum measurement | Resistance gauge |

Ultimate vacuum | 1.0E-1Pa |

Pumping interface | KF16 |

Sliding rail | Can achieve the sliding of two temperature zone furnace, to realize rapid temperature rise and fall. |

Power supply | AC220V 50Hz |