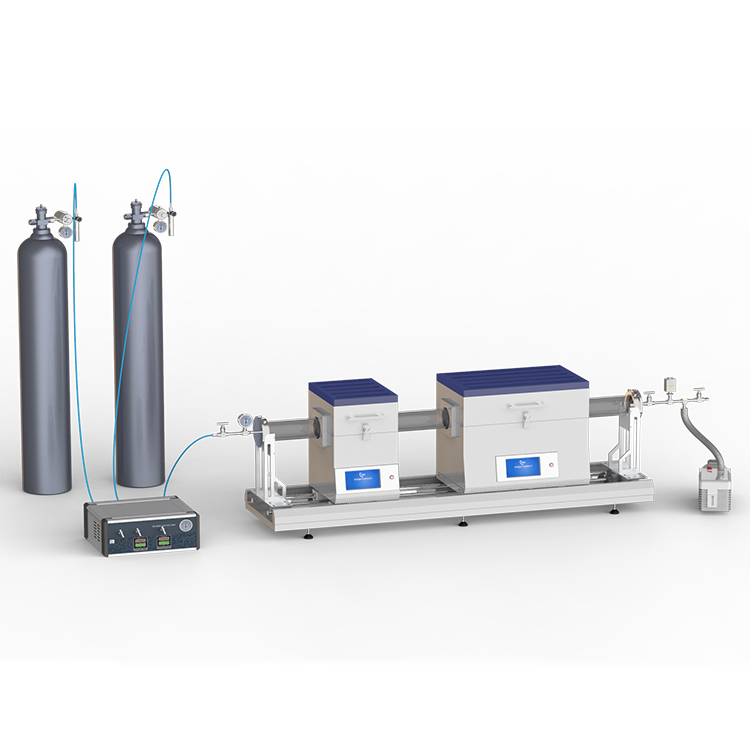

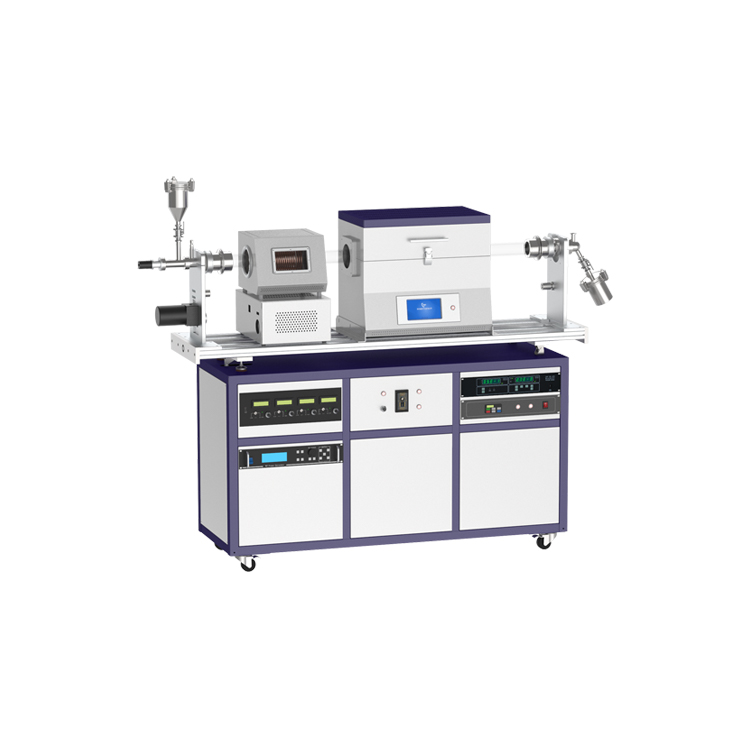

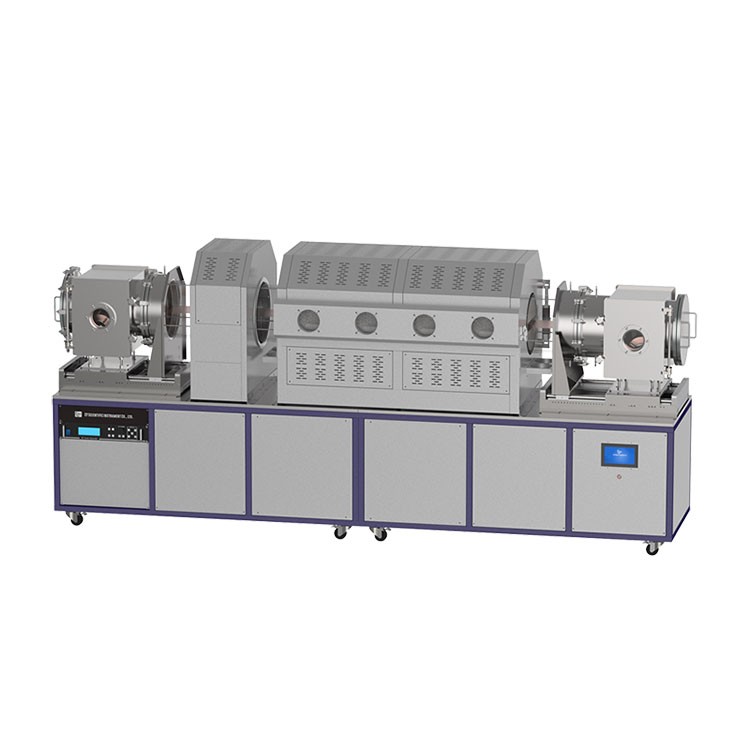

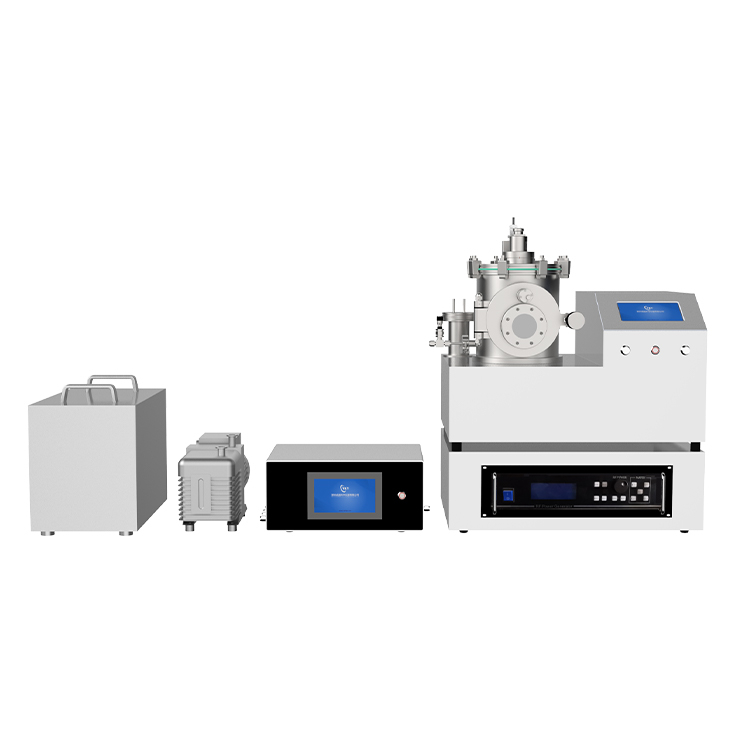

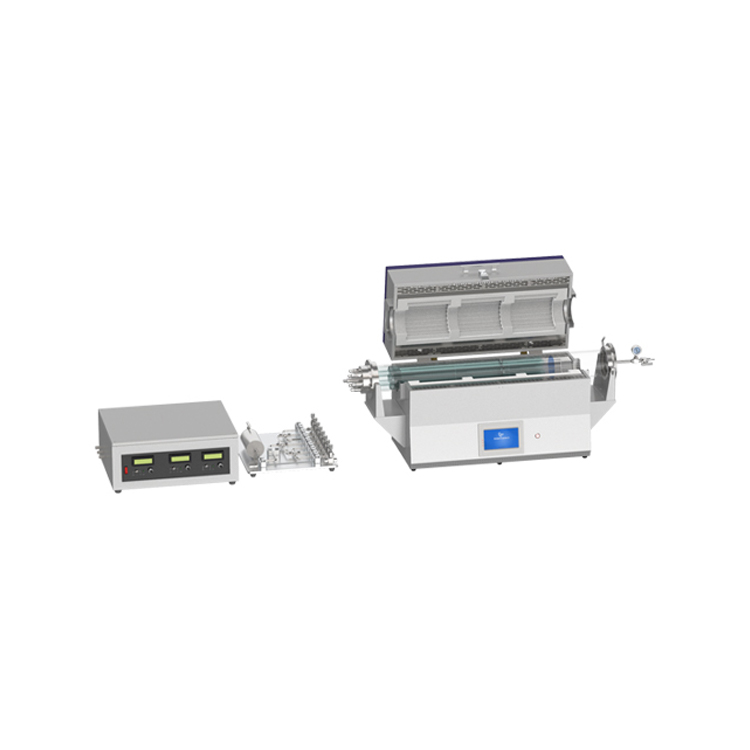

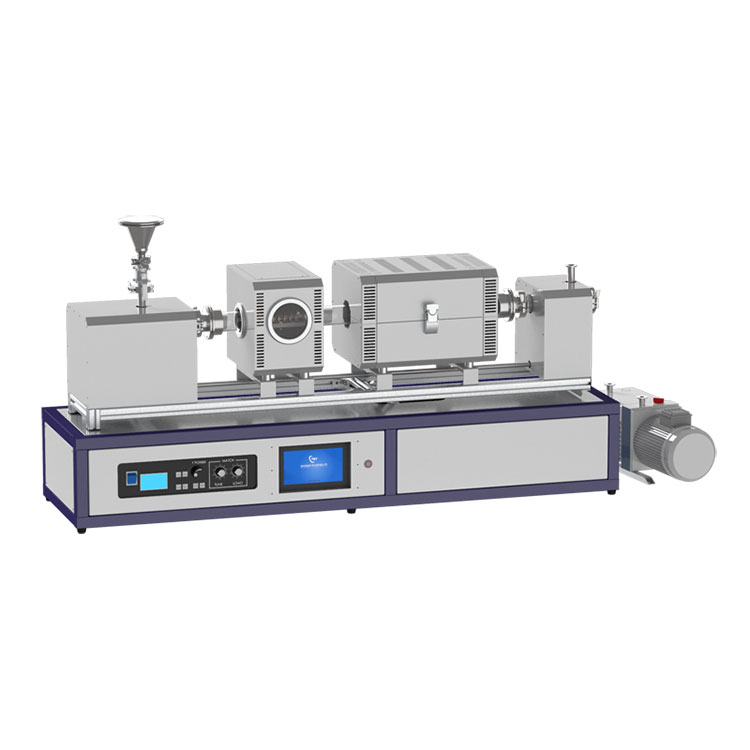

The two-dimensional material growth device is composed of a preheating furnace, a reaction furnace, a vacuum system, a gas supply system, and a sliding rail support. The preheating furnace can be used to preheat and evaporate the solid state source, and the reaction furnace can provide the thermal environment required for the reaction. Both electric furnaces are mounted on the slide rail support, which can realize rapid temperature rise and fall, and increase the efficiency of the experiment. Thermocouple temperature measurement is provided in the furnace tube to precisely control the reaction conditions. All circuits are controlled by high-definition full-color touch screen, which is easy to operate and easy to use.

The gas supply system adopts two-channel mass flowmeter, which has precise flow control and simple and intuitive operation. The vacuum system adopts high-quality two stage rotary vane vacuum pump with the vacuum degree of 10E-1Pa, which fully meets the needs of CVD crystal growth experiments.

Two-dimensional molybdenum sulfide growth equipment application:

This product is mainly used in growth experiments of two-dimensional materials by CVD method, especially for the preparation of two-dimensional molybdenum sulfide.

Two-dimensional molybdenum sulfide growth equipment technical parameters:

Preheating furnace | Model | CY-O1200-100I-T-S |

Chamber length | 300mm |

Heating zone length | 200mm |

Constant temperature zone | 100mm |

Working temperature | 0~1100℃ |

Temperature control accuracy | ±1℃ |

Temperature control mode | 30 or 50 segment program temperature control |

Display mode | LCD (HD full color touch screen) |

Power supply | AC:220V 50/60Hz |

Single heating zone tube furnace | Model | CY-O1200-100I-T |

Chamber length | 440mm |

Heating zone length | 400mm |

Constant temperature zone | 200mm |

Working temperature | 0~1100℃ |

Temperature control accuracy | ±1℃ |

Temperature control mode | 30 or 50 segment program temperature control |

Display mode | LCD (HD full color touch screen) |

Power supply | AC:220V 50/60Hz |

Furnace tube | Tube material | High purity quartz |

Tube length | Φ100mm×1800mm |

Sealing method | 304 stainless steel vacuum water cooled flange |

Flange interface | 1/4" ferrule connector |

Gas supply system | Flowmeter | Two-channel mass flowmeter |

Flow range | MFC1 range: 0~200SCCM MFC2 range: 0~200SCCM |

Measurement accuracy | ±1.5% F.S |

Repeatability | ±0.2% FS |

Linear precision | ±1%F.S. |

Response time | ≤4s |

Work pressure | -0.15Mpa~0.15Mpa |

flow control | LED highlight digital tube display, button adjustment Each channel gas contains a needle valve for individual control |

Intake interface | Can be connected to 1/4NPS or 6mm outer diameter stainless steel tube |

Outlet interface | Can be connected to 1/4NPS or 6mm outer diameter stainless steel tube |

Connection method | Double ferrule connector |

working temperature | 5~45℃ |

Exhaust system | Mechanical pump | Rotary vane pump |

Pumping rate | 1.1L/S |

Exhaust interface | KF16 |

Vacuum measurement | Resistance gauge |

Ultimate vacuum | 1.0E-1Pa |

Power supply | AC:220V 50/60Hz |

Pumping interface | KF16 |

Sliding Rail | Rail length | 1.8m~2m It can realize the sliding of the length of one furnace position of two furnaces, and realize the rapid temperature rise and fall. |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.