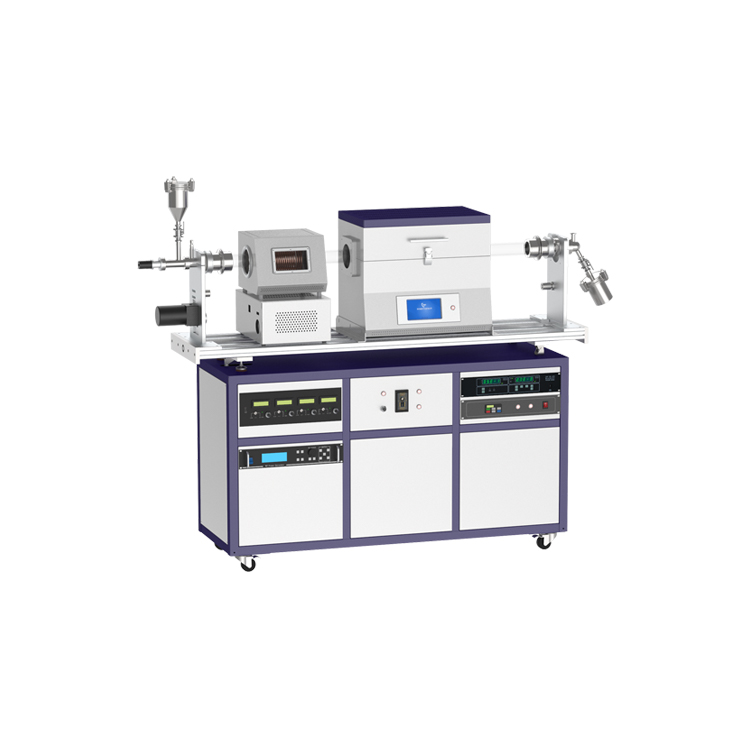

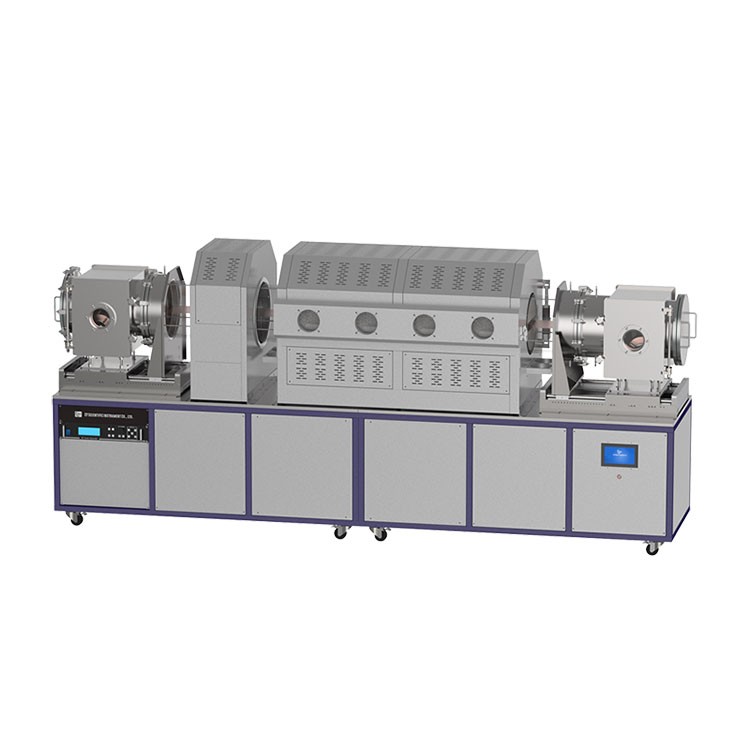

The three temperature zones of the tube furnace are independently temperature controlled by the precision temperature control instrument. By adjusting the temperature of each temperature zone, the tube furnace can form three temperature gradients in the heating zone or form a long constant temperature zone. Each zone can be edited with 30 sections of temperature rise and fall, with overheating and open circuit protection. The flanges on both sides of the furnace tube are equipped with a digital vacuum gauge and a mechanical pressure gauge, which can be used to control the atmosphere environment in the pipeline.

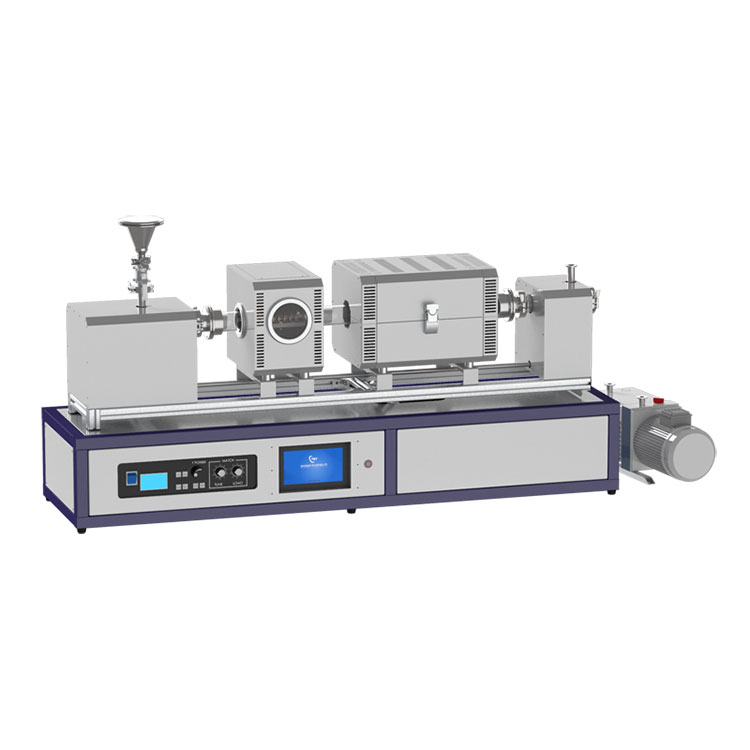

If you need to maintain a single grain structure (such as when drying or calcining materials), a rotary tube furnace is ideal for you. The combination of continuous rotary motion and atmospheric protection of the furnace tube enables the mixing and mixing of the materials in the tube to achieve uniform heating effect, which will bring you the ideal treatment result.

1200℃ low vacuum rotary CVD system applications:

The main application fields of the equipment are: powder metallurgy, ceramics, refractory materials, lithium battery anode and cathode materials, new energy and other industries particle powder firing, calcining, determination of materials.

1200℃ low vacuum rotary CVD system technical parameters:

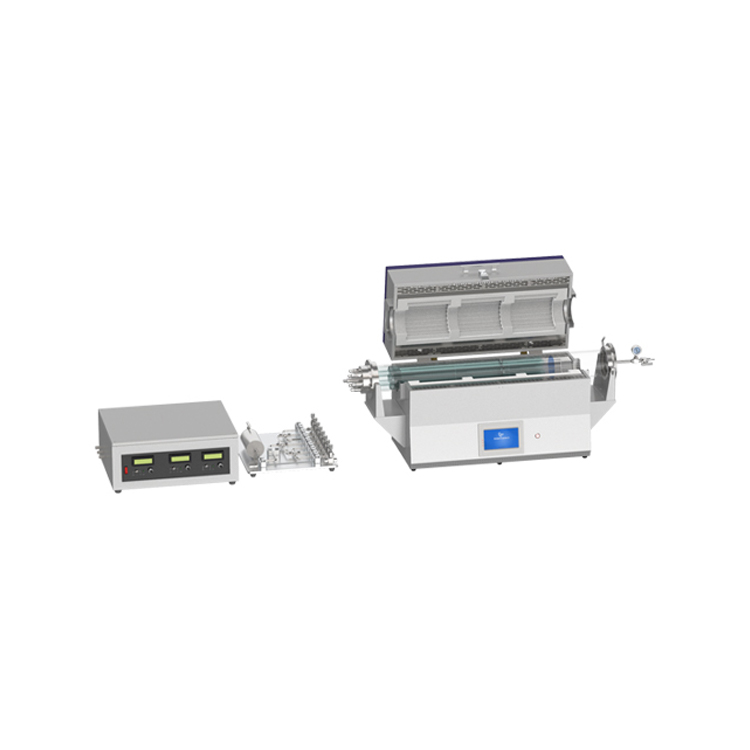

Vacuum tube furnace | Max power | 4.5kw |

Tube material | High purity quartz |

Tube diameter | 60mm at both ends, 100mm in the middle |

Tube length | 1400mm |

Furnace chamber length | 600mm |

Heating zone length | 200mm+200mm+200mm |

Operating temperature | 0~1100℃ |

Temperature control accuracy | ±1℃ |

Temperature control mode | 30 or 50 segment program temperature control |

Display mode | Highlight digital display |

Sealing method | 304 stainless steel vacuum flange |

Flange interface | 1/4" ferrule connector, KF16/25/40 joint |

Vacuum | 4.4E-3Pa |

Power supply | AC:220V 50/60Hz |

Inclination angle | 0~15° |

Rotating speed | 0~20 rpm |

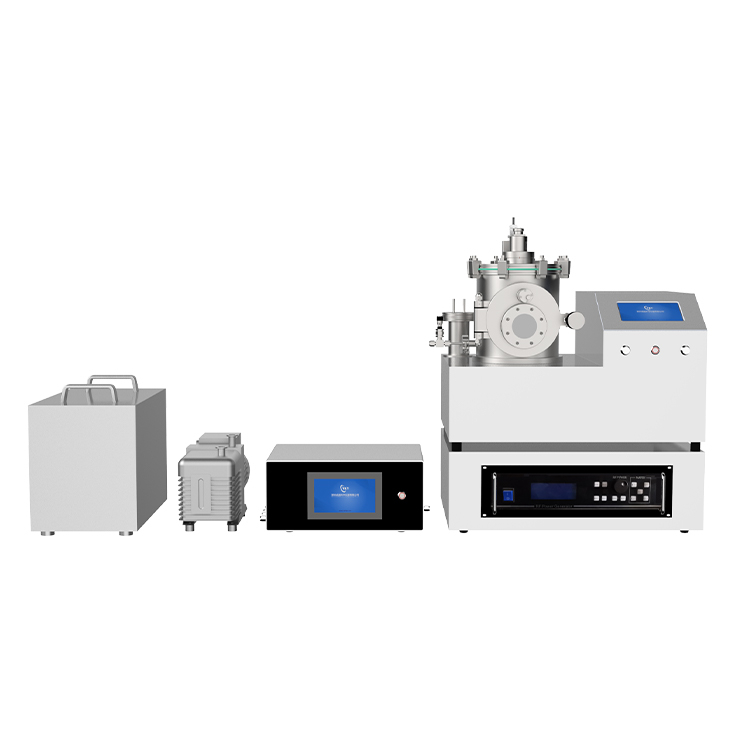

Gas supply system | Model | CY-3F |

Gas channel | 3-channel |

Measuring unit | Gas float flowmeter |

Measuring range | A channel: 0~100ml H2 gas | Remarks: If you need other ranges or gas types, you need to specify when ordering. According to the customer's specific requirements, the flow meter of the corresponding gas type and range can be selected. |

B channel: 16~160ml N2 gas |

C channel: 25~250ml Ar gas |

measurement accuracy | ±2.0% |

Pipe pressure resistance | 3MPa |

Working pressure difference | 50~300KPa |

Connecting pipe | 304 stainless steel |

Gas channel | 304 stainless steel needle valve |

Interface specification | 1/4" ferrule connector for gas inlet and outlet |

Exhaust system | Mechanical pump | Rotary vane pump |

Pumping rate | 1.1L/S |

Exhaust interface | KF16 |

Vacuum measurement | Resistance gauge |

Ultimate vacuum | 1.0E-1Pa |

Power supply | AC:220V 50/60Hz |

Pumping interface | KF16 |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.