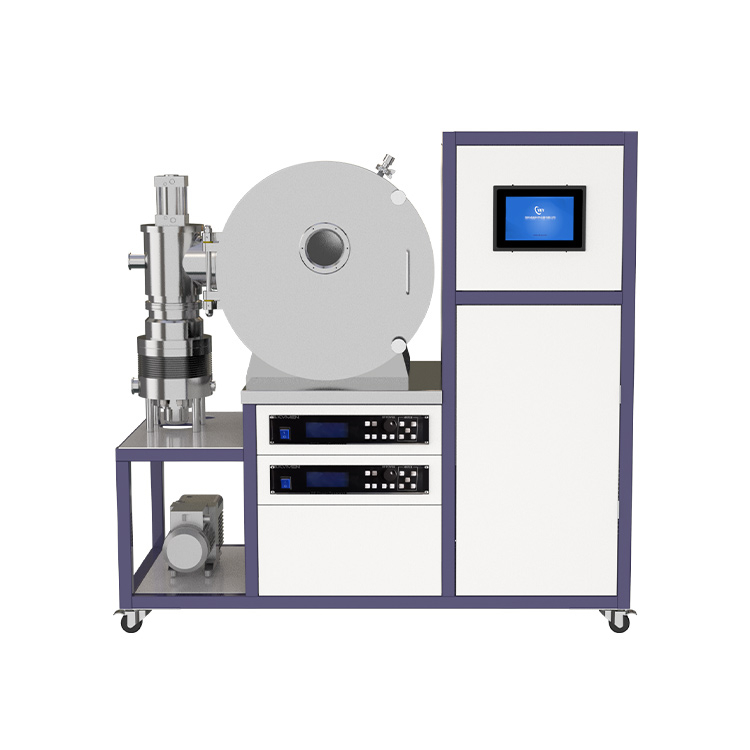

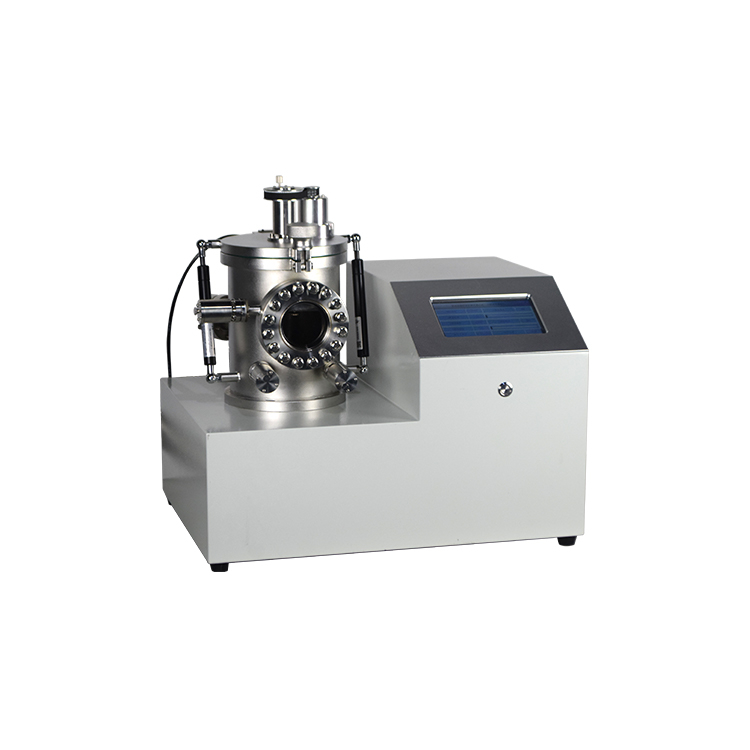

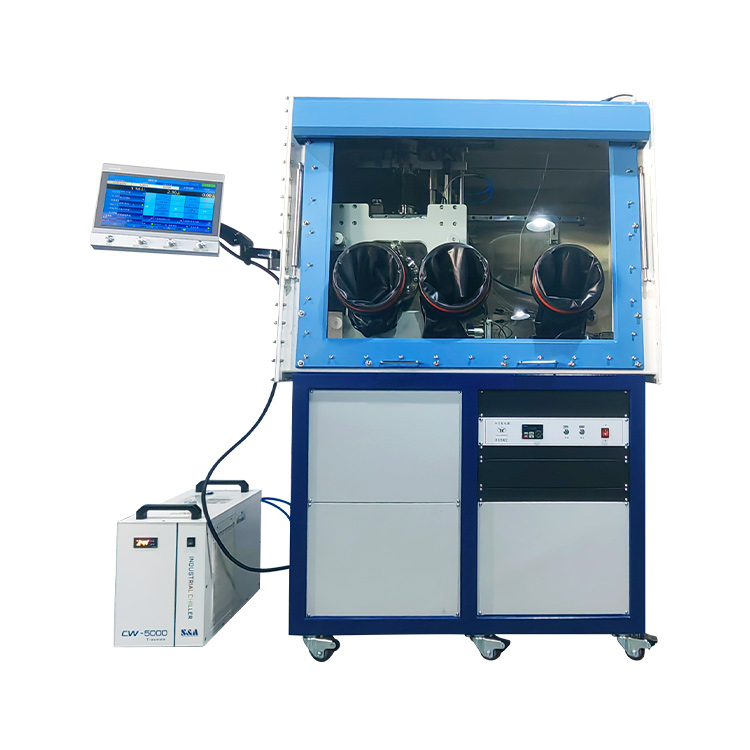

This equipment is multi-source high vacuum evaporation coater, the equipment adopts the front door vacuum chamber design, the chamber space is large, the expansibility is strong, can meet the evaporation coating of multiple large size samples. The chamber is equipped with an upper sample table, which can select the clamping or cassette type sample mounting parts according to the user's sample style. The sample table can be rotated, heated and lifted, all operations are integrated through the touch screen control. The vacuum pump group of the equipment is a two -stage vacuum system, which is composed of a bipolar rotary vane vacuum pump and a turbomolecular pump, which can provide a clean and oil-free high vacuum environment for vacuum coating test. The vacuum system contains a complete pneumatic valve system, the user can through the touch screen for one -click operation to achieve vacuum extraction, without stopping to take lofting, complete shutdown and other operations.

The evaporation source of the equipment is two groups, taking tungsten boat evaporation source, water-cooled copper electrode, can support the maximum 300A large current, heating temperature up to 1800℃, can achieve a variety of refractory metal evaporation. The equipment adopts the integrated design, the cavity and the electric control part are separated from each other, which realizes the separation of water and electricity, and effectively ensures the safety of users. The electronic control part uses the combination of touch screen and button panel design, vacuum system, sample table and other auxiliary functions through the touch screen one -click operation, electrification evaporation, film thickness control through the panel independent operation, as convenient as possible to the user while avoiding the possibility of misoperation. The device has perfect design and superior performance, and is an essential choice for high-precision evaporation coating test in the laboratory.

Multi-source high vacuum evaporation coating instrument |

Sample Table | Measurements | φ150mm sample |

Height | 150mm adjustable up and down |

Evaporation source | Quantity | Tungsten Boat x2 |

Vacuum chamber | Cavity size | Phi 350 x600mm |

Viewing window | Front φ100mm with blackout |

Cavity material | 304 stainless steel |

Opening method | Front door opening type |

Film thickness control | Crystal vibration type film thickness measuring instrument, optional multi-channel film thickness controller |

Vacuum System | Forepump | Bipolar rotary vane pump |

Air extraction connector | KF16 |

Secondary pump | Turbo molecular pump |

Pumping interface | ISO160 |

Vacuum measurement | Resistance + ionization composite vacuum gauge |

Exhaust rate | Mechanical pump 1.1L/s Molecular pump 600L/s |

Ultimate vacuum | 1.0 e-5 Pa |

Power supply | AC 220V 50/60Hz |

Pumping rate | Rotary vane pump: 1.1L/S |

Flowmeter | Optional one mass flowmeter 500sccm Ar gas |

Control system | PLC automatic control operation interface: touch screen + operation panel |

Other | Supply voltage | AC220V,50Hz |

Overall dimensions | 1200mm X 900mm X 1500mm |

Machine weight | 500kg |

Machine power | 5kW |