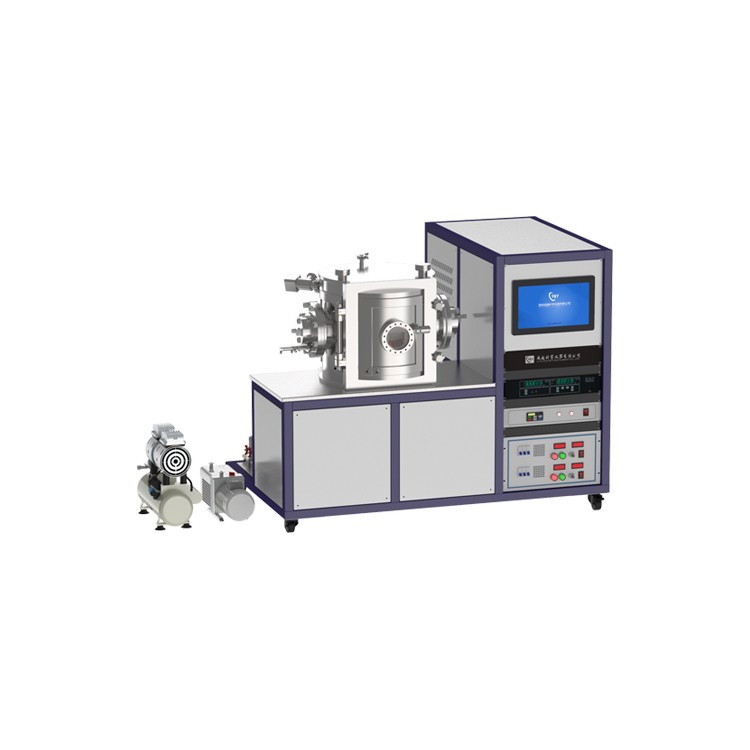

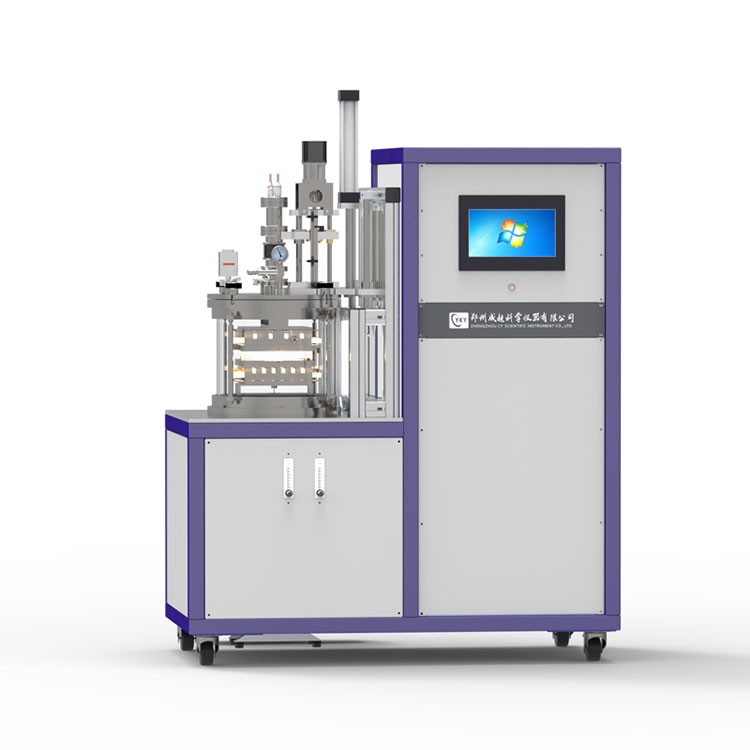

high-vacuum evaporation coater with two sources, tungsten filament basket (or tungsten boat) is used as the evaporation source, and distance between sample table and evaporation source is adjustable. The instrument can stably evaporate metals and some organics. High-vacuum stainless steel chamber is adopted, which has good sealing performance and excellent vacuum performance. The chamber is equipped with an observation window, so the coating process is visible. Ultimate vacuum 10E-5Pa with molecular pump system, effectively improve the coating quality, and can meet the vacuum environment required for most evaporation coating experiments.

high vacuum evaporation coater Technical parameters:

Input power | AC 220V, single phase, 50Hz |

Evaporation current | 100A |

Electrode voltage | 10V |

Evaporation source | Quantity: 2 Tungsten filament basket ×2 pcs, tungsten boat ×2 pcs |

Evaporator baffle | Yes |

Sample holder | Top setting Diameter: φ65 mm Rotating speed: 0-20 rpm The distance between sample holder and evaporation source is adjustable |

Vacuum chamber | Inner wall processing: electrolytic polishing Chamber dimension: ~φ180mm×H210mm Chamber material: 304 stainless steel Opening mode: top open |

Temperature measurement | B type thermocouple |

Display screen | 7-inch touch screen |

Current regulation | Touch screen setting, range 0~100A |

Vacuum required | Rotary vane pump or molecular pump group can be selected as required. (additional charge) |

Extraction interface | KF25 |

Inlet interface | Diameter 6mm round hole fine tuning valve |

Film thickness monitor | Accuracy: 0.1Ã Measurement speed: 100mS-1S adjustable Measurement range: 500 000Ã (Aluminum) Standard sensor crystal: 6MHz |

high vacuum evaporation coater video: