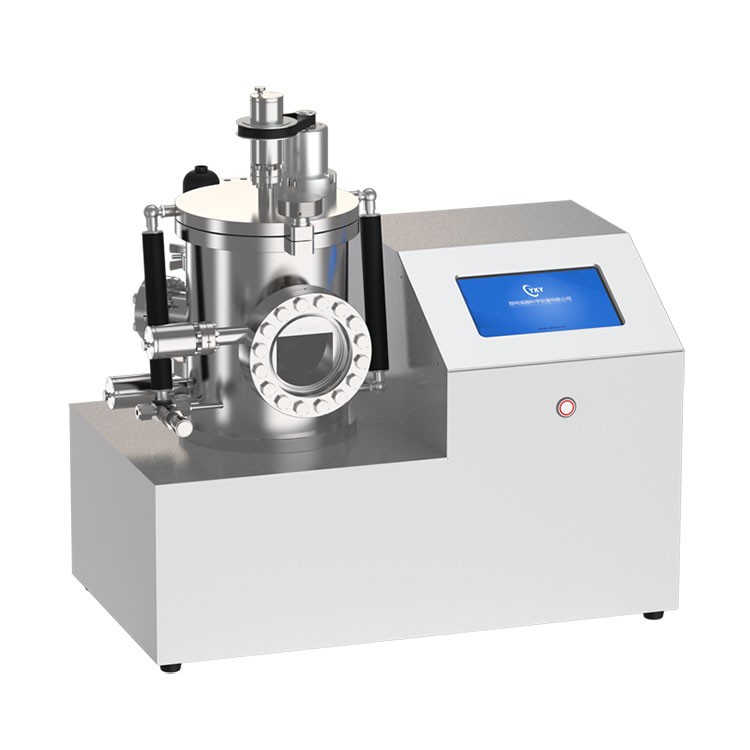

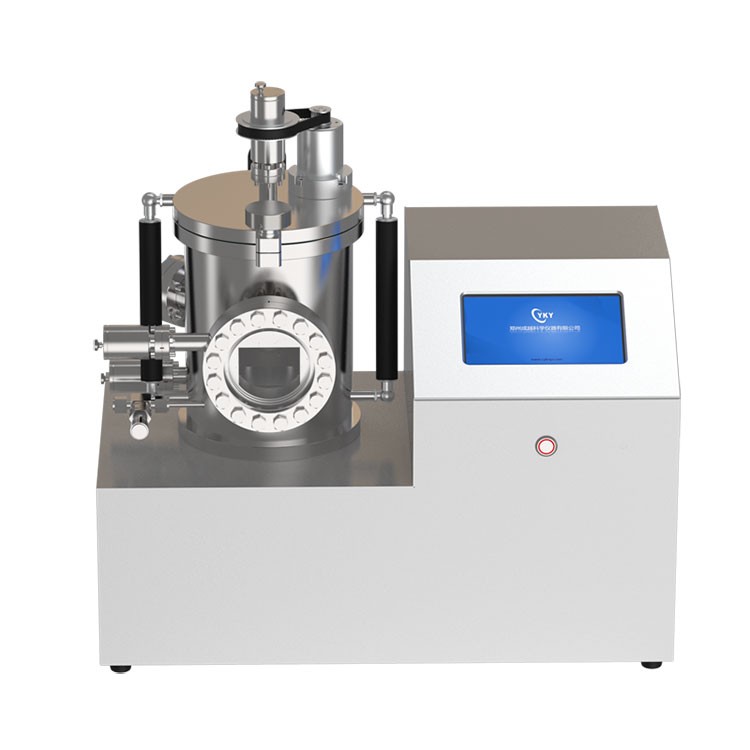

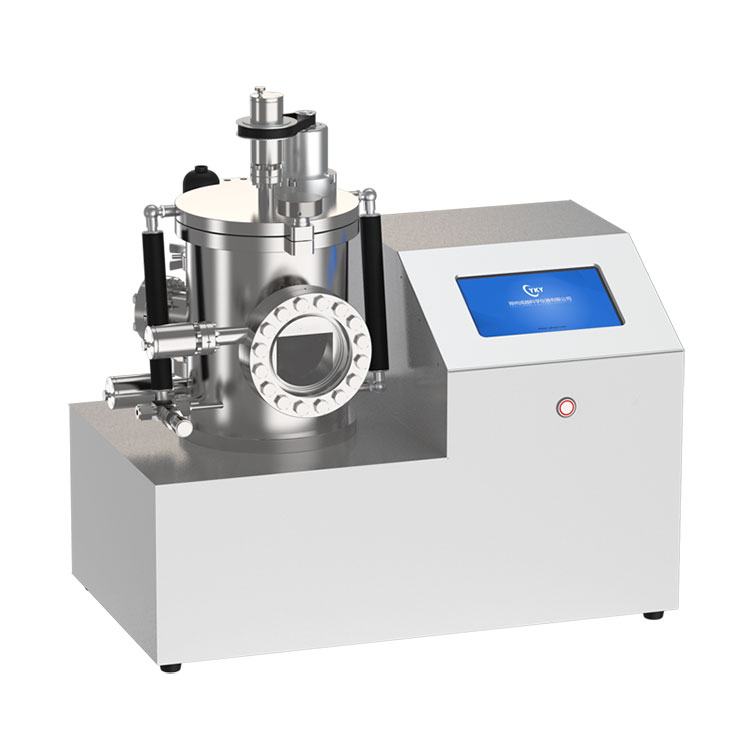

1、 Evaporation source voltage: 10V 2、 The evaporation current is continuously adjustable from 0 to 100A 3、 With a tungsten boat, a tungsten basket; 4、 Stainless steel sample table, diameter of 60mm; 5、 The distance between the sample platform and the evaporation source is adjustable from 60 to 100mm; 6、 The vacuum cavity is a stainless steel cavity with an outside diameter of 170mm , an inside diameter 160mm and a height of 210mm; 7、 It is equipped with quartz observation window with baffle, the size is φ60mm 8、 The air pumping interface of the vacuum chamber is KF40; 9、 Air intake interface is 1/4 inch double ferrule joint; 10、 Touch screen is 7inch color touch screen; 11、 Adjustable sputtering current ,sputtering safety current value and safety vacuum value can be set; 12、 Safety protection: over current, vacuum is too low automatically cut off the sputtering current; 13、 Ultimate vacuum:1Pa(matching double stage rotary vane pump); 14、 Vacuum measurement is Parana vacuum gauge ,the range is:1~105Pa |