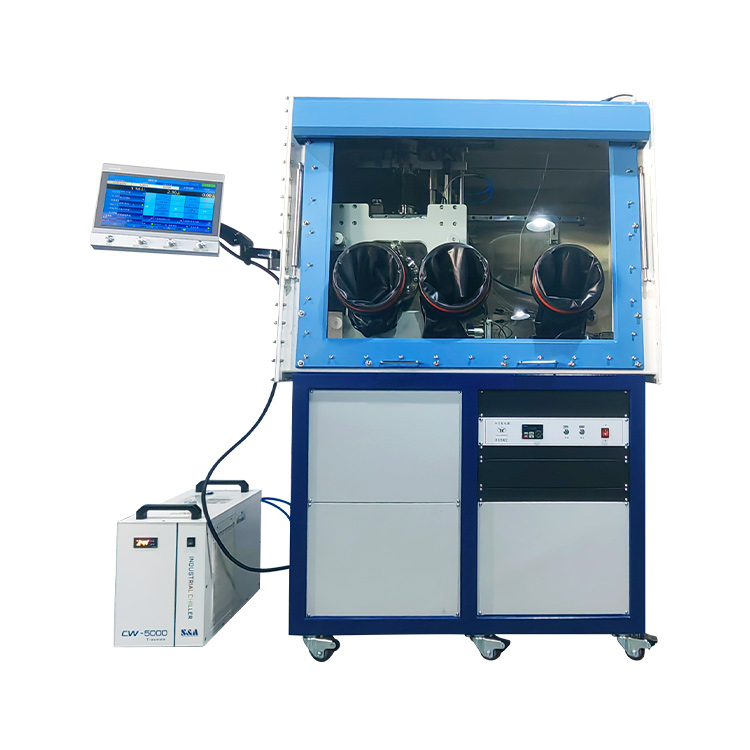

The heating element consists of 20 infrared lamps, which are located at the top and bottom The distance between the two heating tables can be adjusted by a DC motor In order to reduce heat radiation and achieve a faster cooling rate, the heating element is installed in a stainless steel housing with a water-cooled sandwich (stainless steel housing is made of 316 stainless steel). Aluminum nitride ceramic sheet (5"×5"×0.5mm thickness) with high thermal conductivity is used as the loading platform to achieve better heating uniformity A 5"×5" graphite crucible can be placed on the bottom loading table to hold the evaporated material When using this instrument, it is necessary to use a circulating water cooler (KJ-5300 type, 16L/min). |