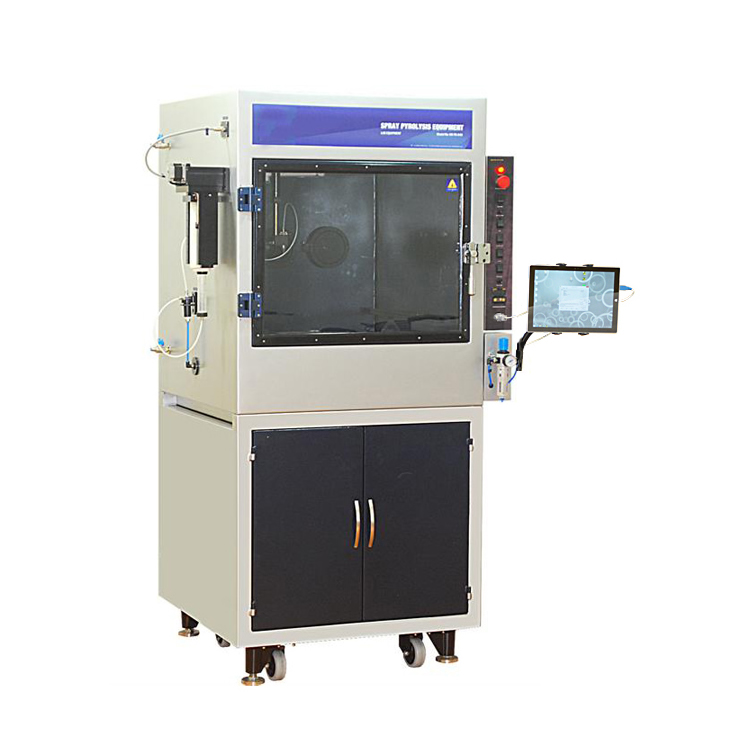

The precision X-Y-Z travel mechanism is built inside the vacuum chamber, which will carry the spray nozzle to the desired position for coating locally. Travel Distance: ( X-Y axis ) 200 mm Max Z axis: 60 mm Max. Travel Speed: 1mm/s - 12mm/s One set of substrate plate with 36 cylinder mask is built in the bottom of the chamber. Standard cylinder mask size: 18 mm diameter. Other sizes are available upon request. The heating plate is installed at the bottom of the substrate plate for pyrolysis treatment. Temperature Range: RT - 500ºC Max. ( < 30 minutes) Temperature Uniformity: ≤±5℃ |