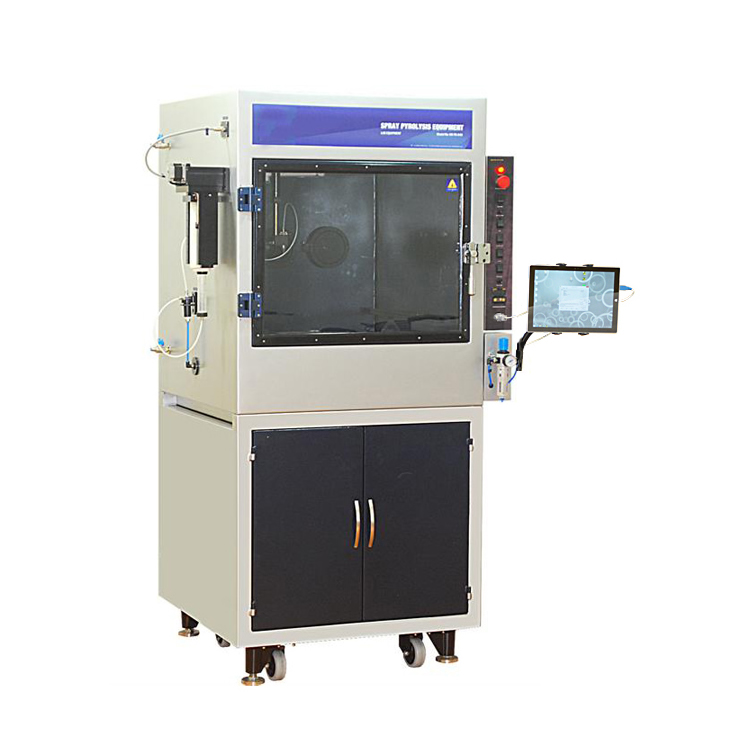

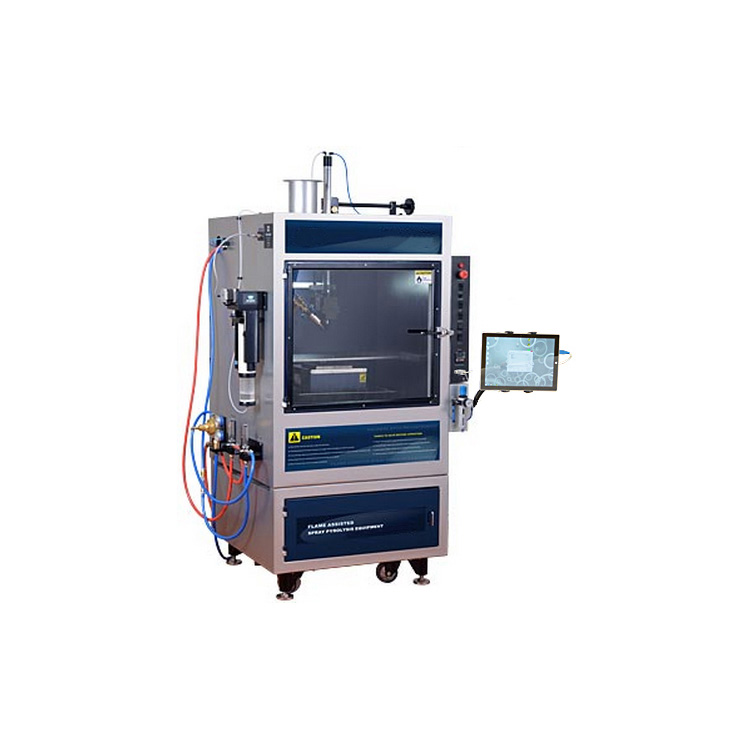

• Three compressive gas spray heads are included to enable multilayer film coating • Each spray head can be used to spray a different type of solution. A masking disc inside the chamber (flip shutter), which can be moved from outside using a knob/lever, is used to prevent the substrate from being exposed to droplets during spray head changeover. • Producing a fine spray of droplets of 50 microns average size • Fluid viscosity range: 1 - 50 mPa•s (cP) • Sprayer traverse: X - Y 200 mm max • Drive speed X axis: 10-800 mm / sec • Drive speed Y axis: 1-12 mm / sec |