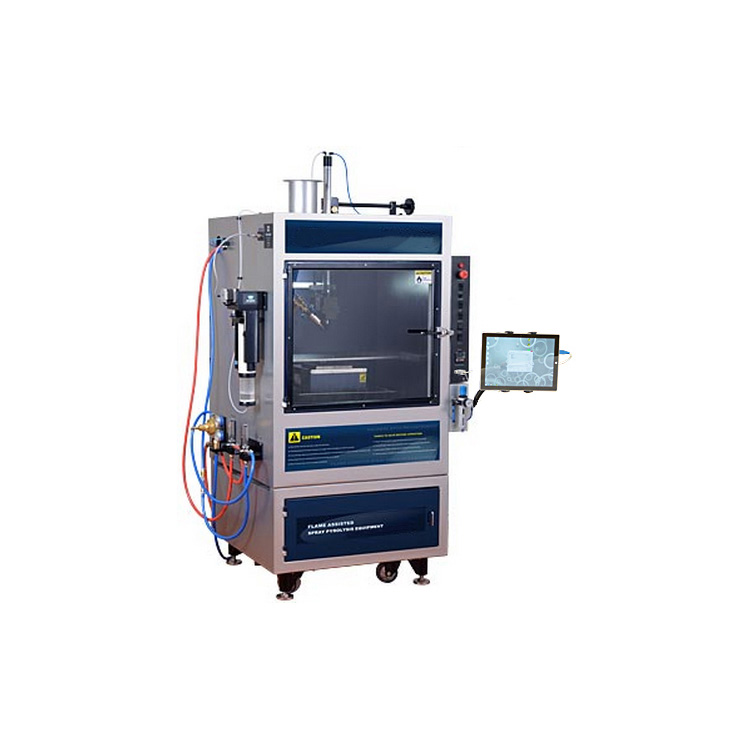

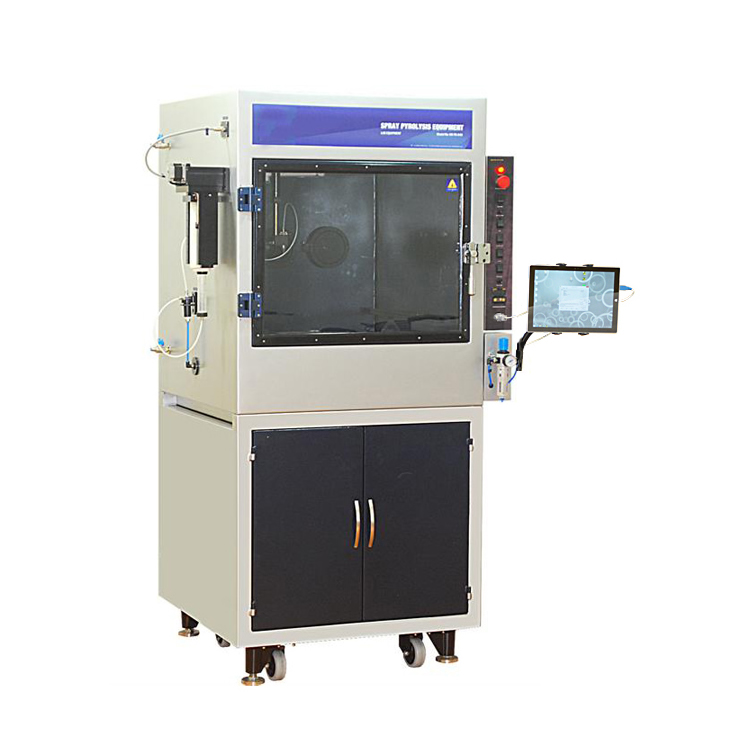

Large floor-stand automatic ultrasonic spray pyrolysis coating unit can be separated from the bottom shelf section for use as a table top unit. This unit also provides for Nitrogen purging of the enclosure. The parameters of the ultrasonic spray pyrolysis ( USP) equipment, like dispensing rate of the solution and the speed of spray head movement, can be precisely controlled by program. A positive displacement pump controlled by the stepper motor and microprocessor is used to dispense solution as per requirement. The ultrasonic spray head provides thinner particle coating and its movement is controlled by the stepper motor driven linear stages in X and Y direction to ensure uniform coating. The temperature of the substrate heater plate is controlled independently through a dedicated controller.

Large floor-stand automatic ultrasonic spray pyrolysis coating unit specifications:

Power Input | Single phase 208 - 240VAC, 50/60Hz |

Actuator | Stepper motor, 24VDC |

Dispensing | • Three Spray heads are included: o Ultrasonic spray head: for thinner film coating o Compressive air spray: for thick film o 20ml Syringe Pump with compressive air for the expensive solution of the thick film.

• Dispensing unit capacity: 50ml & 250ml ( two containers included ) • Dispensing rate: 1-10ml / sec. adjustable via software. • One brand new laptop computer or one Microsoft Surface Pro with pre-installed software is available for controlling. |

Sprayer

| • Ultrasonic atomizer nozzle: 40 KHz, 130W • Producing a fine spray of droplets of 50 microns average size • Fluid viscosity range: 1 - 50 mPa•s (cP) • Sprayer traverse: X - Y 250mm max. • Drive speed X axis (min-max): 10-800mm / sec • Drive speed Y axis (min-max): 1-12mm / sec |

Pressure Regulator & Gauge

| • Pressure regulator with digital gauge is installed on the machine for precise air pressure control. • Digital pressure gauge is operated by 3V lithium battery ( included ) |

Air Compressor | • Compressed air with a pressure of ~ 4 bar is required for normal operation of the unit • One Compact air compressor is included for immediate use • Attention: If a gas cylinder is used instead of air compressor, a two-stage pressure regulator must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. |

Substrate base plate | • Dimension: 250×250mm • Max. temperature: 500℃ • Digital temperature controller |

Communication Port | RS232 (computer with windows OS can be used to control the operations through this serial port) |

Warranty | One year limited with lifetime support |

Compliance | CE certified |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.