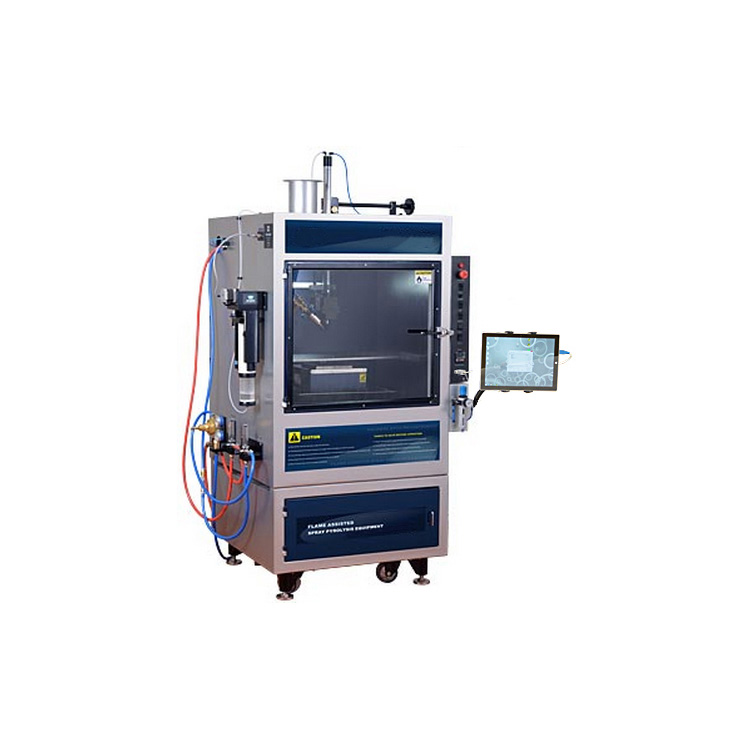

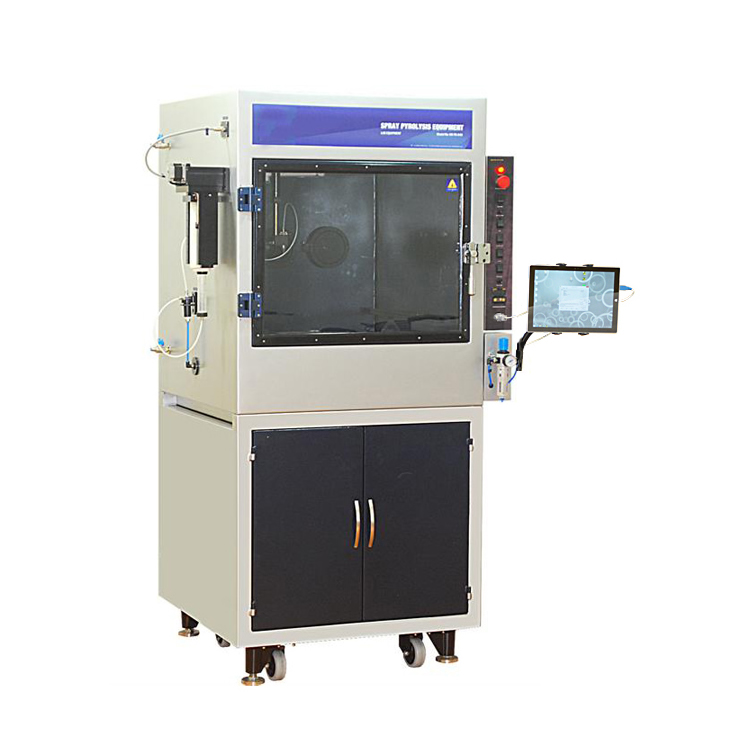

Flame assisted spray pyrolysis equipment is fitted with accessories required for controlling the flame during the process. The solution is sprayed using a positive displacement pump and compressed air through a mixing chamber and nozzle. The substrate is placed on a hot plate, the temperature of which can be set at the desired level through a dedicated controller. The hot plate is mounted on a motorized XY platform to move the substrates during the coating process in the required sequence so that uniform coating is achieved.

Flow rate of the solution and motion sequence of the substrate are controlled through a personal computer. The flame is initiated and set at the required intensity level manually using the control accessories fitted with the equipment. As the solution is sprayed with the help of compressed air, the equipment can be used for spray pyrolysis without flame as well. The combination of pyrolysis thin films with and without flame can also be produced on the same substrates in successive operations.

In flame assisted spray pyrolysis, this spray is heated by a flame produced by an oxy-LPG gas mixture, before being deposited onto the substrate.n this technique, the solution is sprayed onto a heated substrate through an LPG flame.The chemical reactants are selected such that products other than the desired compound are volatile at the temperature of deposition. The process is generally useful for the deposition of oxides onto metal and ceramic substrates and particularly suitable for the deposition of Al2O3, ZnO and metastable solid solutions of ZnO-MgO and ZrO2-Y2O3 on amorphous silica and Nickel based super alloys.

Flame assisted spray pyrolysis equipment specifications:

Input Voltage | AC 208~240V Single phase |

Liquid Dispensing Unit | • Actuator: Stepper motor • Dispensing rate: 1 - 20ml / min. • Dispensing unit capacity: 50ml & 250ml • Syringe pump is controlled by included Laptop computer or Microsoft Surface Pro |

Compressive Air Sprayer

| • One Compressive air spray nozzle is included • Sprayer traverse: X - Y 200mm max. • Drive speed X axis (min-max): 5 - 20mm / sec • Drive speed Y axis (min-max): 2 - 12mm / sec |

Heatable Substrate Base Plate

| • Dimension: 175×175mm • Max. temperature: 500°C • PC connection: RS232 Port • PC Software is included for customer installation |

Air Pump & Gases

| • One compact air compressor (5.5 gals; 220V 50Hz) is included for immediate use. • Oxygen gas and LPG gas are required for operation (not included). • US standard Hose, Regulator, Valve Assembly is included for easy connection to LPG gas tanks. Attention: If a gas cylinder is used instead of air compressor, a two-stage pressure regulator must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. |

Gas Flow Control

| Integrated O2 & LPG gas float meters allow easy adjustment of the gas flow rate and thus the flame size. • LPG Gas Float Meter: 0~2L/min • O2 Float Meter: 0~25L/min |

Ignition System | This system features Automatic Ignition Switch which allows the operator to ignite the flame safely. |

Pressure Regulator & Gauge

| • Pressure regulator with digital gauge is installed on the machine for precise air pressure control. • Digital pressure gauge is operated by 3V lithium battery ( included ) |

Water Cooling | Continuous water circulation for cooling the Flame head is required. • Water temperature < 25C • Pressure ~20PSI • 6mm O.D Water Tubing Inlet/Outlet |

Software | • Centralized software control of almost all of processing parameters. • One software interface for syringe pump, XY target, and rotating drum collector. • All of the process parameters can be saved as user program and retrieved for analysis or rerun. • One brand new laptop computer or one Microsoft Surface Pro with pre-installed software is available for controlling. |

Compliance | CE certified |

Warranty | One year limited with lifetime support (demo before purchase available) |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.