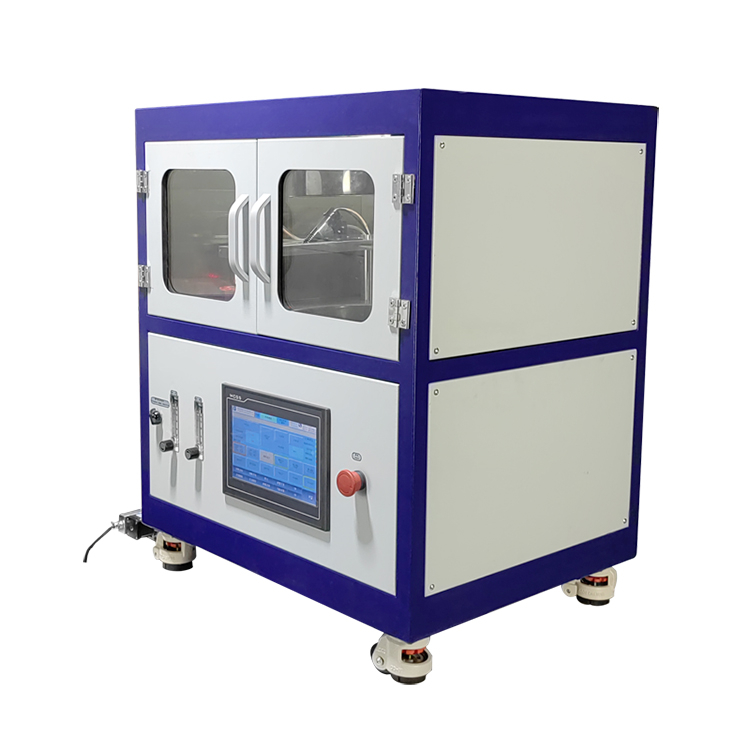

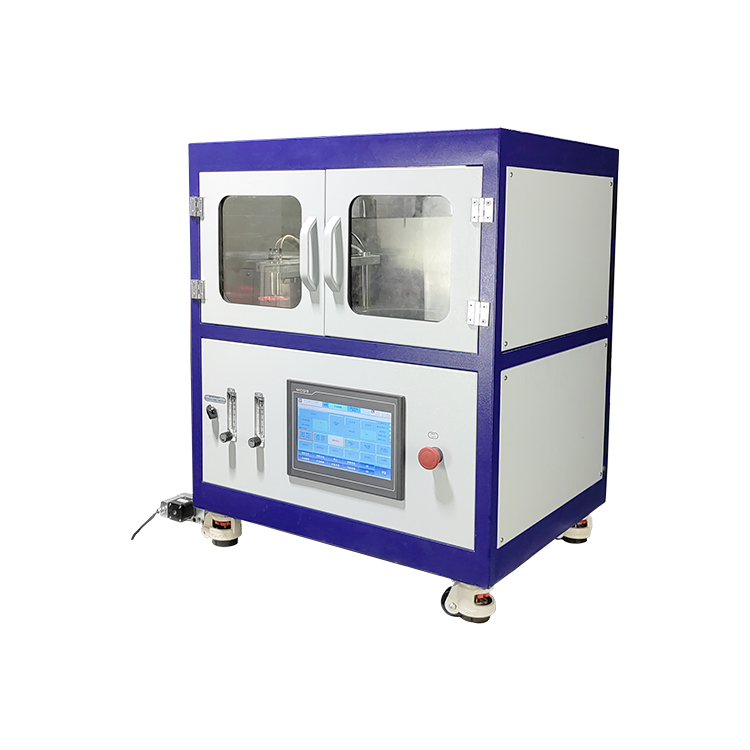

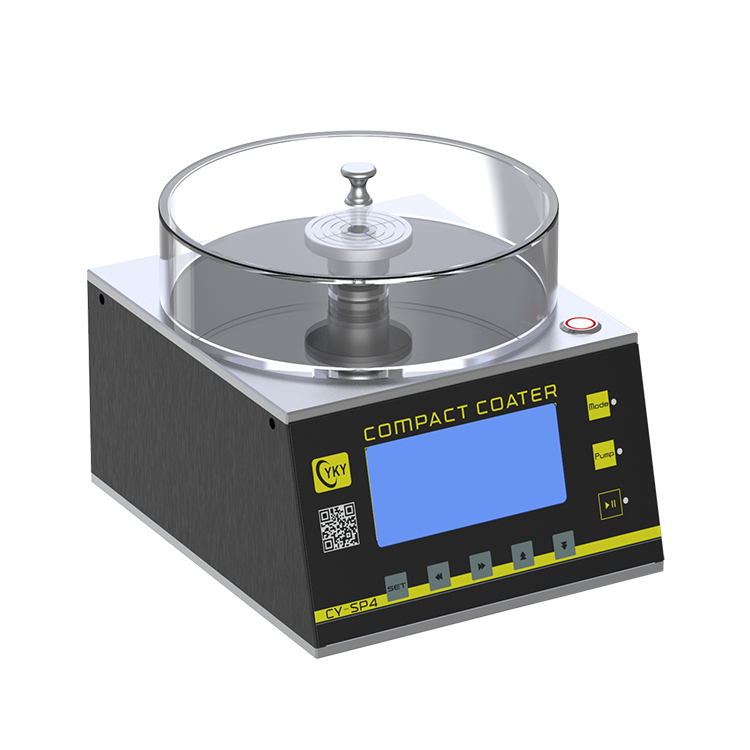

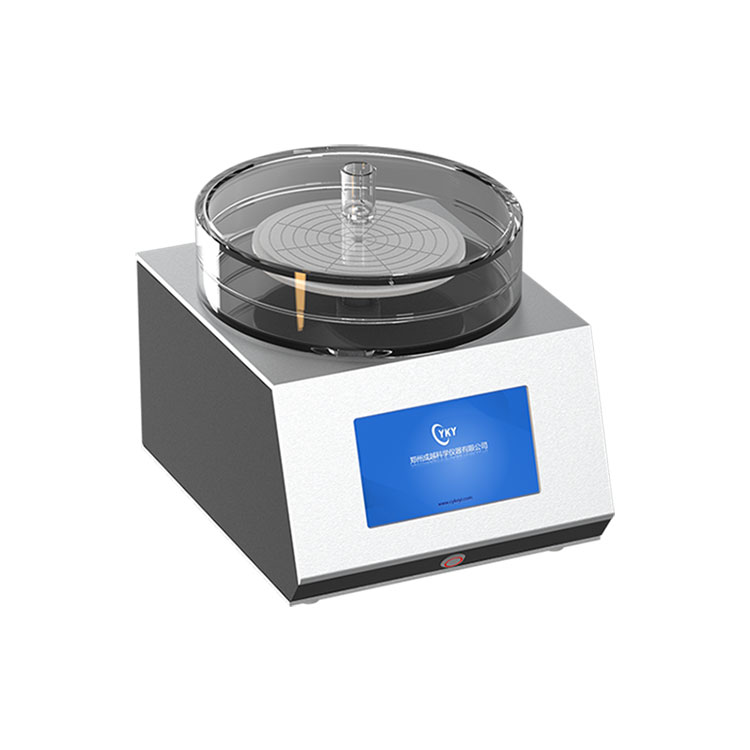

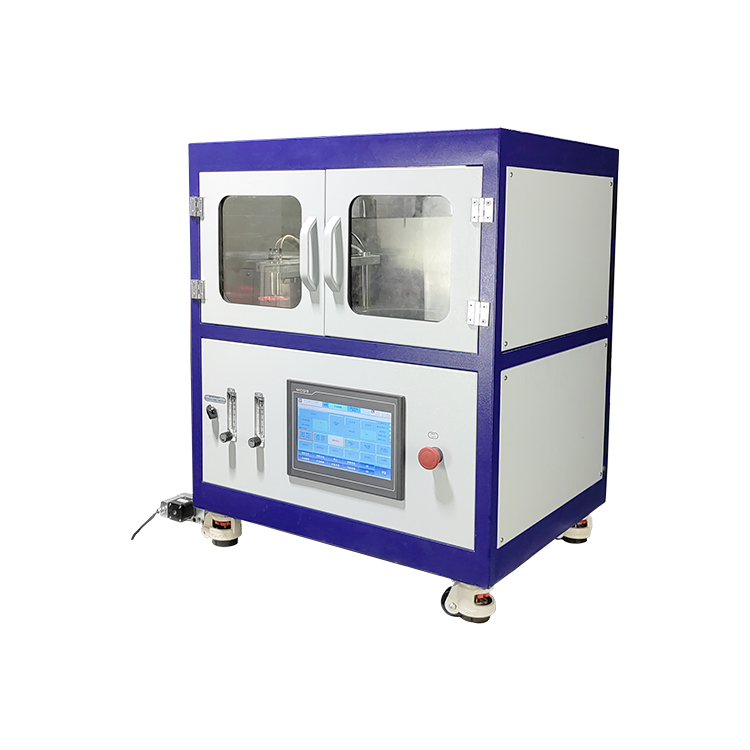

Automatic Ultrasonic Atmosphere Heating Spin Coater is a 300mm diameter, flexible rotary glue dispenser. It can spray the glue on the substrate through an ultrasonic nozzle, and then rotate at a high speed to make the glue evenly coated on the substrate. The spin coating operation can also be perfor,There is a heating element in the cavity, which can be baked after the glue is mixed. The product has a gas path controlled by two-way float flowmeter, which can pass inert gas into the cavity to protect the glue liquid from the influence of gas in the air during glue mixing. This type of glue dispenser is suitable for surface coating of semiconductor silicon wafers, glass slides, wafers, substrates, ITO conductive glass and other processes and plate making. The maximum wafer size that can be glued is 12 inches, the speed can reach 3000rpm, and the acceleration can reach 2000rpm; it has the advantages of stable speed, quick start, convenient operation, etc., and can ensure the consistency and uniformity of the glue thickness. It is a performance Excellent product.

Ultrasonic Atmosphere Heating Spin Coater Product features:

1. Adopt DC brushless motor, controlled by single chip microcomputer

2. High-definition touch screen control

3. Single-step multi-step glue mixing operation can be performed, five programs can be stored, and five-step operations can be set for each program

4. Anti-blocking glue design

5. Aluminum alloy cavity, sturdy and durable

6. With ultrasonic, atmosphere, heating and other auxiliary functions, it can provide various auxiliary functions for the research of glue mixing

Ultrasonic Atmosphere Heating Spin Coater Product parameters:

Product name | Ultrasonic Assisted Atmosphere Dispenser |

Wafer size | 12 inches |

Spinning speed | 30~3000rpm adjustable |

Rotational acceleration | 30~2000rpm/s adjustable |

The longest glue mixing time in a single time | 3000s |

Dispensing cavity size | φ390mm*90mm |

Voltage | 220V 50Hz |

Power | 1.5KW |

Heating temperature | 0-100℃ |

Warranty time | Excluding wearing parts, 1 year, lifetime technical support |

Glue machine vacuum suction cup | 12 inch one (standard); 6 inch one (customized) |

Customized pure mechanical chuck for glue machine | 12" one (additional custom); 6" one (additional custom) |

Oil-free vacuum pump | Model:AP-2000V Power:0.55kw Minimum vacuum:-700mmHg;-92Kpa Maximum Air Flow:200L/min;12M3/h Weight:10kg |

Ultrasonic system

Atomizer head material | Titanium alloy |

Frequency | 50kHz |

Power | 30W |

Flow | 0.55mL/s |

Particle diameter | 25um |

Atomizer head type | Conical |

Atomizer head weight | 0.3kg |

Ultrasonic power supply size | 315*312*135mm |

Ultrasonic power supply weight | 5kg |

Injection pump

Flow range | 0.001uL/min-43.349mL/min |

Power-down memory function | Save the setting parameters, after power on again, no need to set |

Applicable injector specifications | 10uL-1000uL |

Applicable Syringe Specifications | 1mL-60mL |

Heating temperature | 0-100℃ |

Linear speed range | 5um/min-65um/min |

Linear speed adjustment resolution | 5um/min |

Maximum stroke | 140mm |

Stroke resolution | 0.156um |

Rated linear thrust | >90N |

Flowmeter

Control gas types | 2 kinds |

Gas flow rate | 16-160mL/min |