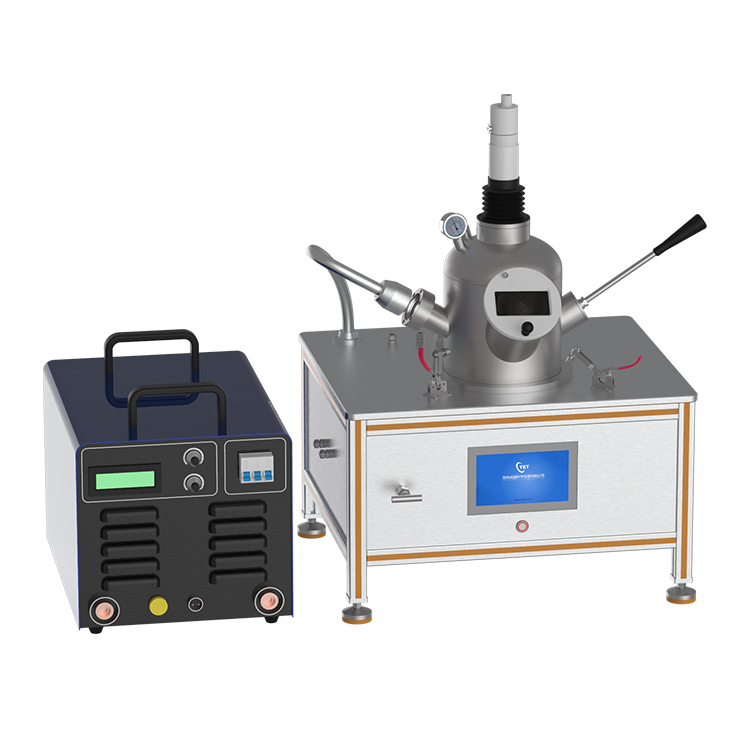

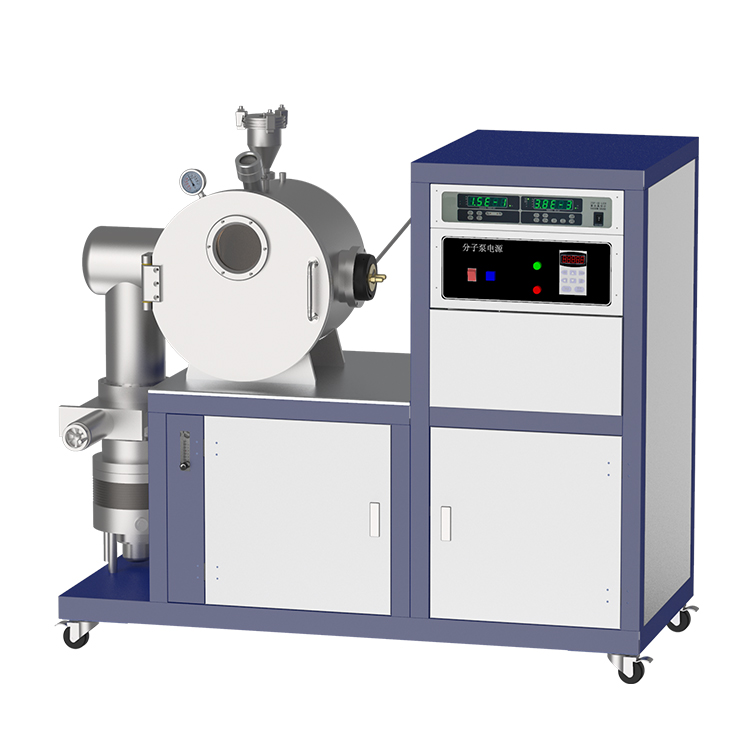

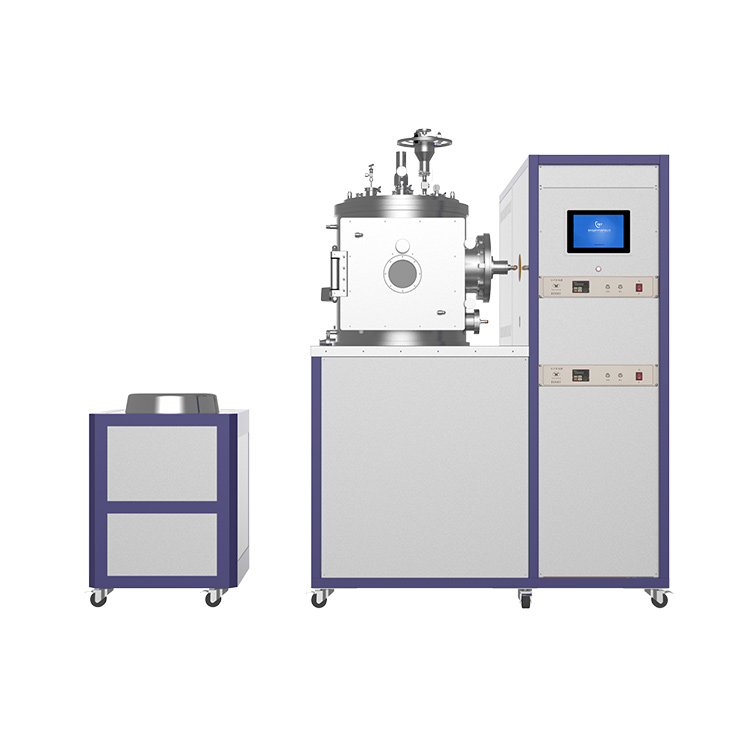

This vacuum induction melting furnace adopts vertical quartz cavity, and both ends are equipped with water-cooled flanges, which can ensure that the entire cavity will not be damaged by thermal shock during operation. The furnace body flange is equipped with a vacuum interface and a protective gas interface, which can be used for vacuum smelting and atmosphere protection smelting, and can effectively ensure that the sample is not oxidized. The induction furnace adopts high-frequency power supply for heating, with fast heating speed and high energy efficiency ratio. It is mainly used for melting and processing of metal materials (such as stainless steel, nickel base alloy, copper, alloy steel, nickel cobalt alloy, rare earth neodymium iron oxide, etc.) under the condition of vacuum or protective atmosphere.

Technical parameters of vacuum induction furnace:

Item | Detail |

Supply voltage | AC380/110V,50Hz |

Maximum power | 35kw |

Maximum temperature | 2000℃ |

Crucible capacity | 2kg (steel liquid) |

Vacuum acquisition | Bipolar rotary vane vacuum pump |

Limit vacuum degree | ≤ 10Pa |

Protective atmosphere | nitrogen, argon ≤ 0.05Mpa |

Dimension | 660×1060×1060mm(L×W×H) |

Weight | 200kg |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.