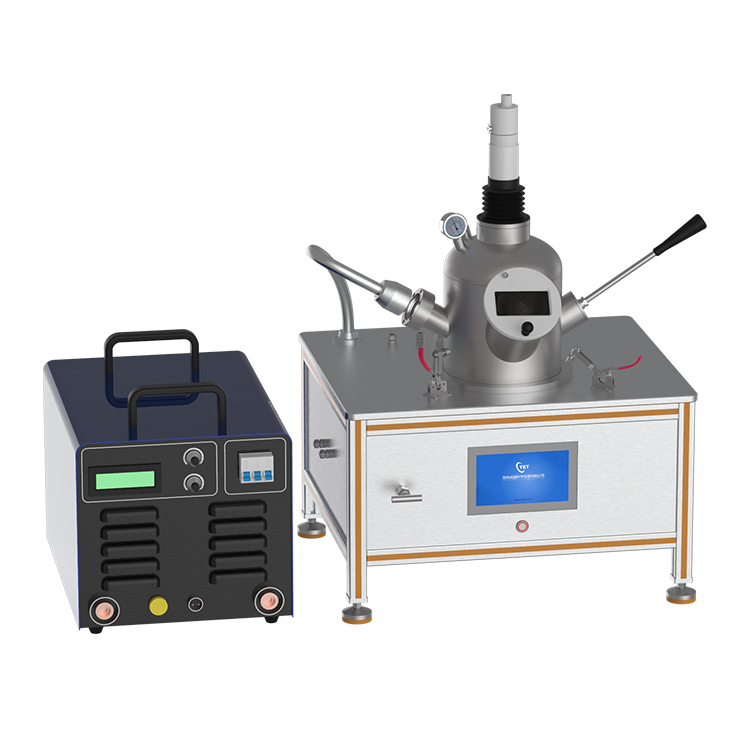

Induction Heater | Working Voltage: 220V AC, 50/ 60 Hz, Three Phase Working Current: 42 Amp (50A breaker required) Max. Input Power: 15KW Output Frequency: 30 - 80 kHz Adjustable Duty Cycle: 80% Induction Coil: 95mm(OD) x 85mm(ID) x 50mm(H) Auto Heating Time: 1-99 seconds Auto Dwell Time: 1-99 seconds Auto Cooling Time: 1-99 seconds Air Cooling: Rear Fan Protection: Automatic water pressure, over-temperature, and overpower protection

|

Vacuum Chamber

& Graphite Crucible | Quartz Tube Vacuum Flange: Stainless Steel Flange with high-temperature silicone o-ring and self-tighten structure Two valves and vacuum gauge installed on the flange. KF25 connector and 1000mm long SS pipe is included for connecting to the vacuum pump

High Purity Graphite Crucible: 2.285"(OD) x 1.415"(ID) x 3.05"(Deep) Crucible (79mL) included for heating and melting Complete refractory assembling made of alumina, including bottom crucible support, crucible holder, and cover. One chamber shield is included to protect the chamber from foreign objects damage as well as containing the exploded piece of the chamber.

|

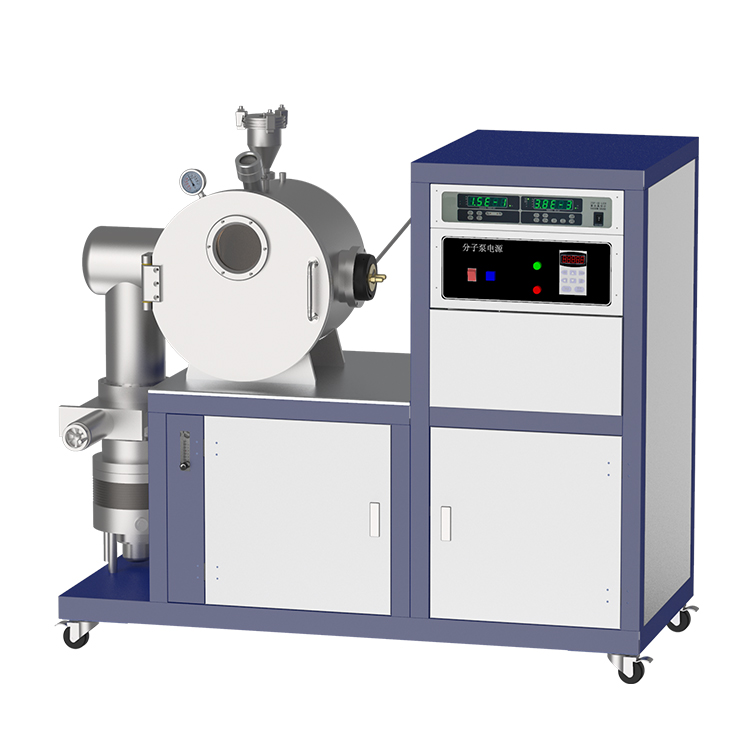

Working Temperature | This induction heating system can reach 2000℃ via graphite heater No temperature controller. The temperature will be determined by sample melting via adjusting current If you need accurate temperature control, please order the induction heating system at CYKY

|

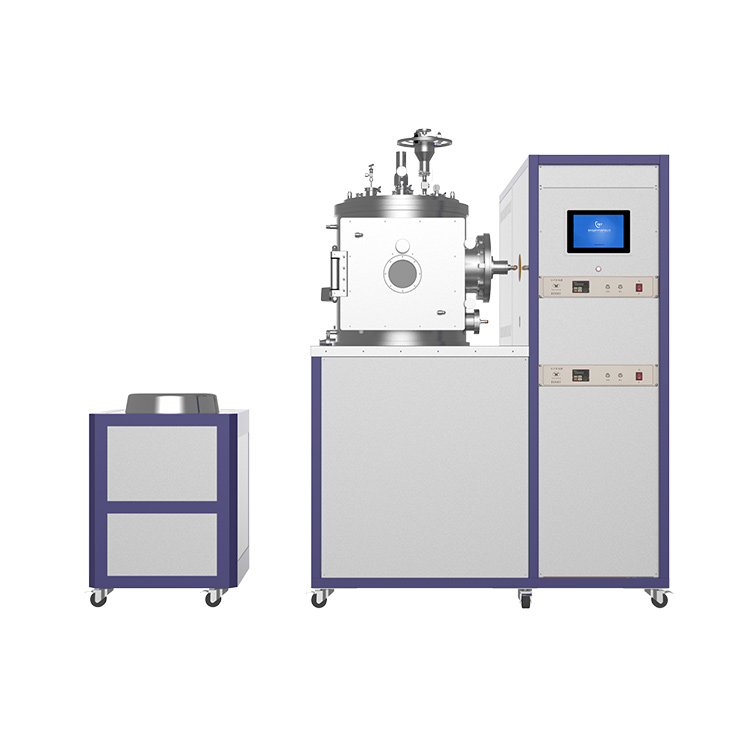

Water Chiller | Temperature range: 5 - 30℃ Water Flow Rate: 16 L/min Water Tank: 12 Liters made of stainless steel Note: It is recommended to use the specific coolant to get the best performance. For US customer, 110V water chiller will be included

|

Vacuum Pump | One 156L/m Rotary Vane Vacuum Pump is included Rate: 156 L/min Max. Power Consumption: 0.4KW / 0.37KW For US customer, 110V Vacuum pump will be included

|

Heavy Duty Mobile Cart

| |

Protective Shield

| For Non-UL Certified version, a protective shield made of phenolic sheets will be provided. For UL Certified version, a clear protective shield made of polycarbonate will be provided. The protective shield is to be placed around the quartz tube to contain the shooting glass shards if accidents were to happen.

|

Product Dimensions | Induction Heater: 18.5"(L) x 12"(W) x 17"(H) (470mm x 300mm x 430mm) Water Chiller: 18"(L) x 8.7"(W) x 28"(H) (460mm x 220mm x 530mm) Heavy Duty Mobile Cart: 600mm(L) x 800mm(W) x 597mm(H)

|

Warranty | One year limited warranty with lifetime support Consumable parts such as processing tubes, o-rings, and heating coil are not covered by the warranty

|

Application Notes | The heater will shut down if over output occurs. Please reduce coil cycle number or sample size to keep the heater operating under Max power Melting time and temperature are related to materials, the crucible, refractory insulation, etc. If you do not know whether the induction heater can melt your sample or not, please contact our engineer for consulting. Have your alloy's composition, melting point, and quantity to be melted prepared The Induction Melting System is designed for use under vacuum and low pressure < 0.02 MPa / 0.2 Bar/ 3 PSI and the flow rate for gases should be limited to < 200 SCCM ( or 200ml/min Attention: A pressure regulator must be installed on your input gas tank and have the output gas pressure set below 3 PSI at all times after opening the gas tank with the gas maintained in a continuous flowing condition. Gas build-up with pressure levels exceeding over 3 PSI may cause irreversible damage to the furnace chamber. Never heat the furnace while the gas release valve is closed and a positive pressure condition exists within the furnace chamber. The pressure gauge must be used to closely monitor the chamber condition at all times during the heating process; please open the gas release valve immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable damages.

|

Net Weight | 105 kg (230 lbs) |