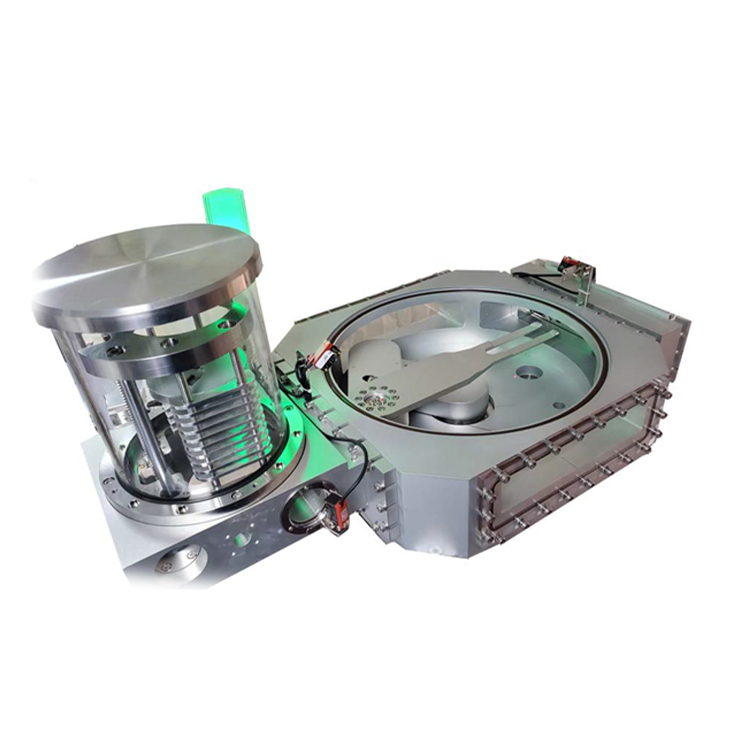

Product introduction: this equipment is three target magnetron sputtering coater apparatus, which can be used for the preparation of metal thin films. It has applications in the fields of electronics, optics, and special ceramic preparation. It can also be used for laboratory SEM sample preparation.

The three target magnetron sputtering coater is equipped with two magnetron targets and two sets of DC power supplies, which can be used to coat multilayer conductive metal films. At the same time, the equipment has two parts: a main chamber and a transition chamber. The transition chamber is equipped with a magnetic push rod, and a vacuum gate valve is installed between the two chambers; The user can load samples in the transition chamber while performing sputtering work in the main chamber, and perform vacuum pre-pumping. After the sputtering in the main chamber is completed, the sample can be pushed into the sample stage of the main chamber through the magnetic push rod. Such a design can reduce the number of vacuum pumping times in the main chamber, which not only effectively saves time, but also ensures a better local vacuum and effectively improves the quality of the coating.

Three target magnetron sputtering coater technical tarameters:

Working Voltage | l VAC 220, 60Hz |

Sputtering Vacuum Chamber | l Dimension: ~ φ325xH510mm l Material: 304 stainless steel l Inner wall processing: electrolytic polishing l Sealing method: Fluorine rubber seal l Viewport (window): ~4'' (100mm) with shutter |

Sample Holder | l Center bottom setting sample holder, with one shutter l Sample holder: Dia. 150mm l Rotary speed: 0~20rpm adjustable l Heating temperature: RT~ 500oC |

Magnetron Sputtering Gun | l Quantity: 3 sets l Adjustable angle -45°~45° l Sputtering orientation downwards l Target dimension: diameter 2'', thickness max.3mm |

Quartz Crystal Monitor | l Channel numbers: One-channel l Accuracy: 0.1Ã l Measurement speed: 100mS-1S adjustable l Measurement range: 500 000Ã (Aluminum as a reference) l Standard sensor quartz crystal: 6MHz |

Vacuum System | Backing Pump | l Double-stage rotary vane pump l Pumping rate: 1.1L/s |

Molecular Pump | l Pumping rate: 600 L/s l Rated rotating speed: 27000rpm l Starting time: <5min l Cooling method: water cooling l Vacuum degree: 5*10-4Pa |

Composite Vacuum Gauge | l Resistance gauge + ionization gauge l Measuring range: 10-5Pa ~ 105 Pa |

DC Power Supply | l Quantity: 2 sets l Output power: 0~500W l Output voltage: 0~600V l Maximum output current: 1A l Starting time: 1~10s |

RF power supply | l Quantity: 1 set l Output power: 0~500W l RF frequency: 13.56 MHz l Matching method: automatch l Reflected power: ≦100W l Power stability: ±0.1% |

Mass Flow Controller | l One-channel MFC for Ar gas l Measuring range: 0~200sccm |

Water Cooler | l Flow rate: 10L/min l Power: 0.1KW l Cooling power: 50W/℃ l Tank capacity: 9L |

Control | l PLC automatic control |

Transition chamber | l The chamber size will be for max. 4inch wafers. l Equipped with one compact molecular pump group l Backing pump: VRD-4, pumping speed: 1.1L/s l Model of molecular pump: TG60F l Pumping speed of molecular pump: 60L/s |

magnetron sputtering coater video: