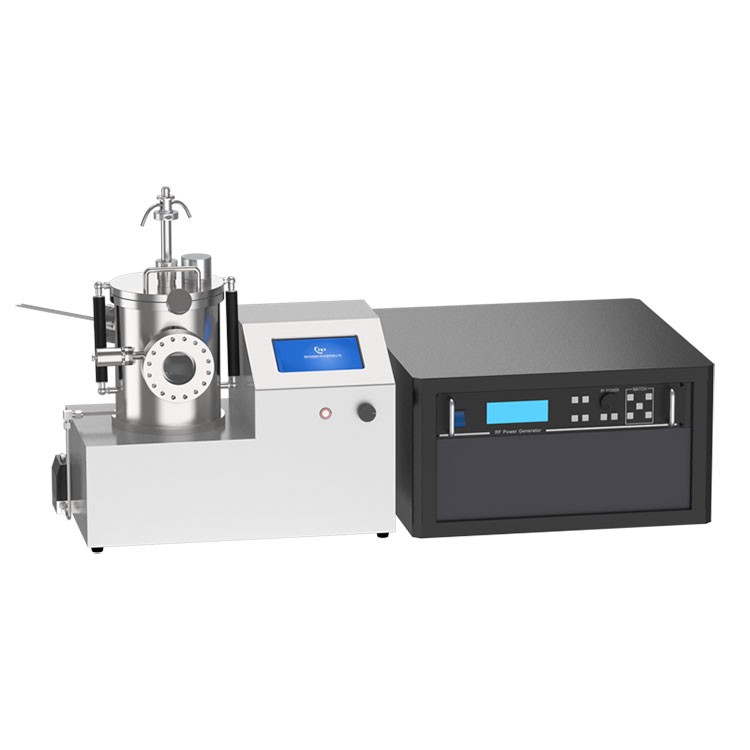

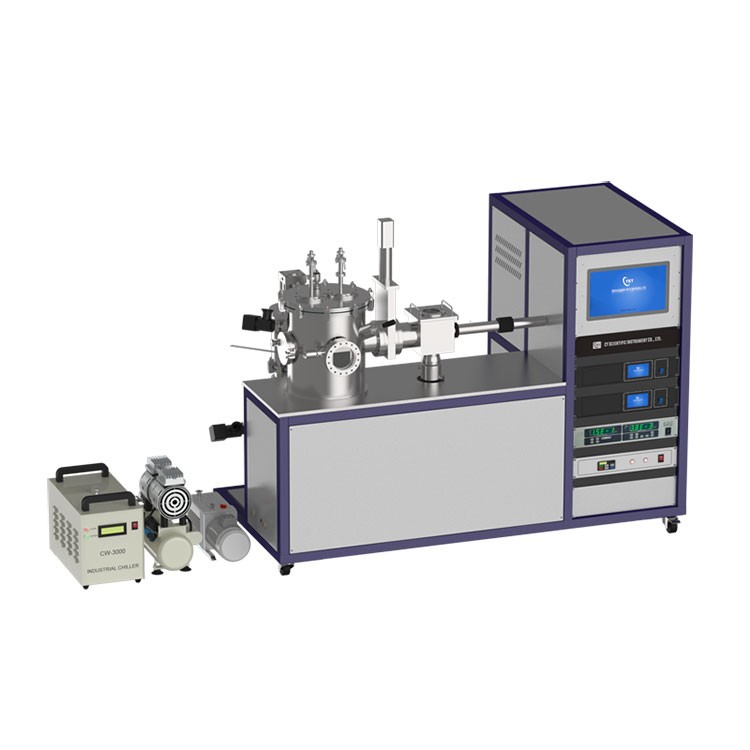

Single target DC magnetron sputtering coater

Single target DC magnetron sputtering coater can be used to prepare single-layer ferroelectric films, conductive films, alloy films, etc. Compared with similar equipment, this single-target magnetron sputtering coating instrument is not only widely used, but also has the advantages of small size and easy operation. It is an ideal equipment for laboratory preparation of material thin films, and is especially suitable for laboratory research on solid electrolytes and OLED etc.

Single target DC magnetron sputtering coater equipment is a cost-effective magnetron sputtering coating equipment independently researched and developed by our company. It has the characteristics of standardization, modularization and customization. Magnetron targets can be selected from 1 inch, 2 inches and 3 inches, and customers can choose according to the size of the plated substrate; The power supply is a 1500W high-power DC power supply, which can be used for high-energy metal sputtering coating. According to experimental requirements, DC or RF power supplies of other specifications can also be selected to achieve coating operations of various materials.

The coating instrument has two high-precision mass flow meters, and customers can customize the gas path of up to four mass flow meters if they have other requirements to meet the requirements of complex gas environment construction; The instrument is equipped with an advanced turbomolecular pump set as standard, and the ultimate vacuum can reach 1.0E-5Pa. At the same time, other types of molecular pumps are available for purchase. The molecular pump's gas path is controlled by multiple solenoid valves, which can open the cavity to take out samples without turning off the pump, which greatly improves your work efficiency. This product can be equipped with an integrated industrial control computer to control the system. The computer program can realize most functions such as the control of the vacuum pump group and the control of the sputtering power supply, which can further improve the efficiency of your experiment.

Application scope of single target magnetron sputtering coater:

Single target DC magnetron sputtering coater can be used to prepare single-layer ferroelectric films, conductive films, alloy films, etc. Compared with similar equipment, this single-target magnetron sputtering coating instrument is not only widely used, but also has the advantages of small size and easy operation. It is an ideal equipment for laboratory preparation of material thin films, and is especially suitable for laboratory research on solid electrolytes and OLED etc.

Technical parameters of single target magnetron sputtering coater:

Single target DC magnetron sputtering coating instrument |

Sample stage | Dimensions | φ185mm |

Heating range | Room temperature~500℃ |

Adjustable speed | 1-20rpm adjustable |

magnetic control target gun | Target plane | Circular plane target |

Sputtering vacuum | 10Pa~0.2Pa |

Target diameter | 50~50.8mm |

Target thickness | 2~5mm |

Insulation voltage | >2000V |

Cable specifications | SL-16 |

Target head temperature | ≦65℃ |

real null Cavity body | Inner wall treatment | Electrolytic polishing |

Cavity size | φ300mm × 300mm |

Cavity material | 304 stainless steel |

Observation window | Quartz window, diameter φ100mm |

Open method | Top opening, cylinder auxiliary support |

gas body control system | Flow control | Mass flow meter, range 0~200SCCM argon gas |

Control valve type | Solenoid valve |

Control valve static state | Normally closed |

Measuring linearity | ±1.5%F.S |

Measurement repeatability | ±0.2%F.S |

Measuring response time | ≤8 second(T95) |

Working pressure range | 0.3MPa |

Valve body pressure | 3MPa |

Working temperature | (5~45)℃ |

Body material | Stainless steel 316L |

Valve body leakage rate | 1×10-8Pa.m3/s |

Pipe joints | 1/4″Compression fitting |

Input and output signal | 0~5V |

Power supply | ±15V(±5%)(+15V 50mA, -15V 200mA) |

Overall dimensions mm | 130 (width) × 102 (height) × 28 (thickness) |

Communication Interface | RS485 MODBUS protocol |

DC power supply | Power | 500W |

Output voltage | 0~600V |

Timing length | 65000 second |

Start Time | 1~10 second |

Film thickness measurement | Power requirements | DC:5V(±10%) Maximum current 400mA |

Resolution | ±0.03Hz(5-6MHz),0.0136Å / Measurement (aluminum) |

Measurement accuracy | ±0.5% thickness + 1 count |

Measurement period | 100mS~1S/time (can be set) |

Measuring range | 500,000 Å (aluminum) |

Crystal frequency | 6MHz |

Communication Interface | RS-232/485 serial interface |

Display digits | 8-digit LED display |

Molecular pump | Molecular pump pumping speed | 80L/S |

Rated speed | 65000rpm |

Vibration value | ≦0.1um |

Start Time | ≦4.5min |

Downtime | <7min |

Cooling method | Air-cooled |

| Cooling water temperature | ≦37℃ |

Cooling water flow rate | 1L/min |

Installation direction | Vertical ±5° |

Suction port | 150CF |

Exhaust connection | KF40 |

Fore pump | Pumping rate | 1.1L/S(VRD-4) |

Ultimate vacuum | 5×10-2Pa |

Power supply | AC:220V/50Hz |

Power | 400W |

Noise | ≦56db |

Suction port | KF40 |

Exhaust connection | KF25 |

Release valve | Pneumatic and electronically controlled air release valve is installed on the vacuum chamber |

The ultimate vacuum of the whole machine | ≦5×10-4Pa |

Vacuum chamber boost rate | ≦2.5Pa/h |

Software system | 1 set of monitoring and management software |

Test target | 2 copper targets with a diameter of 2 inches and a thickness of 3 mm |