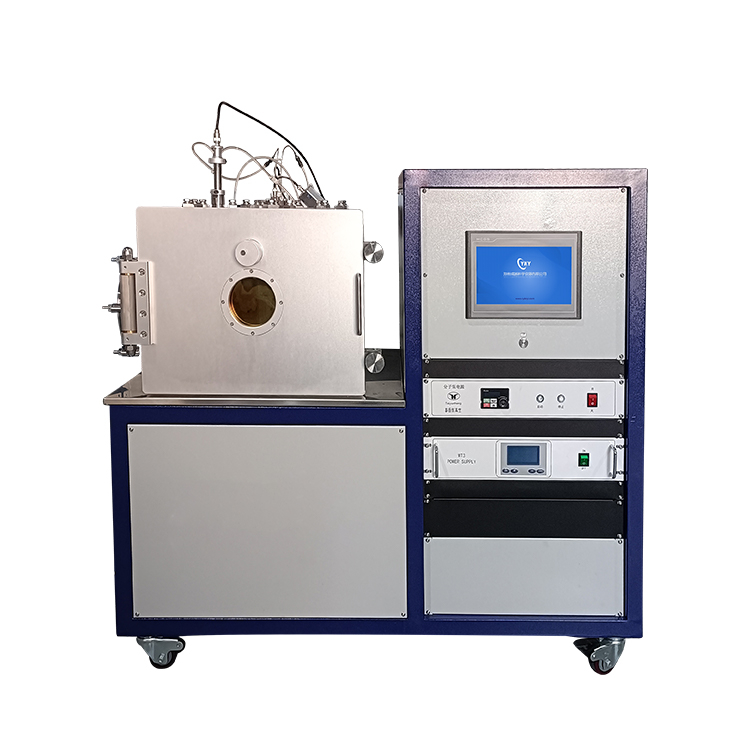

Single target DC magnetron sputtering coater for oxide film

Single target DC magnetron sputtering coater can be used to prepare single or multi-layer ferroelectric film, conductive film, alloy film, semiconductor film, ceramic film, dielectric film, optical film, oxide film, hard film,polytetrafluoroethylene film and so on

Introducing our Single Target DC Magnetron Sputtering Coater, the ultimate solution for all your film preparation needs. This professional-grade equipment is designed to deliver exceptional performance and precision, making it the ideal choice for a wide range of applications.

With our Single Target DC Magnetron Sputtering Coater, you can effortlessly prepare single or multi-layer ferroelectric films, conductive films, alloy films, semiconductor films, ceramic films, dielectric films, optical films, oxide films, and even hard films. This versatility ensures that you can achieve the desired results for various materials and coatings.

Equipped with advanced technology, our coater guarantees outstanding efficiency and reliability. The magnetron sputtering process ensures uniform and controlled deposition, resulting in high-quality films with excellent adhesion and uniform thickness. This ensures consistent and reproducible results, meeting the highest industry standards.

Our Single Target DC Magnetron Sputtering Coater is designed with the utmost precision and attention to detail. The user-friendly interface allows for easy operation and control, while the robust construction ensures long-lasting performance. Additionally, the equipment is equipped with safety features to ensure a secure working environment.

Invest in our Single Target DC Magnetron Sputtering Coater and elevate your film preparation capabilities to new heights. Experience the power of advanced technology combined with professional-grade performance. Trust in our equipment to deliver exceptional results, every time.

Specification parameters:

Single target DC magnetron sputtering coater |

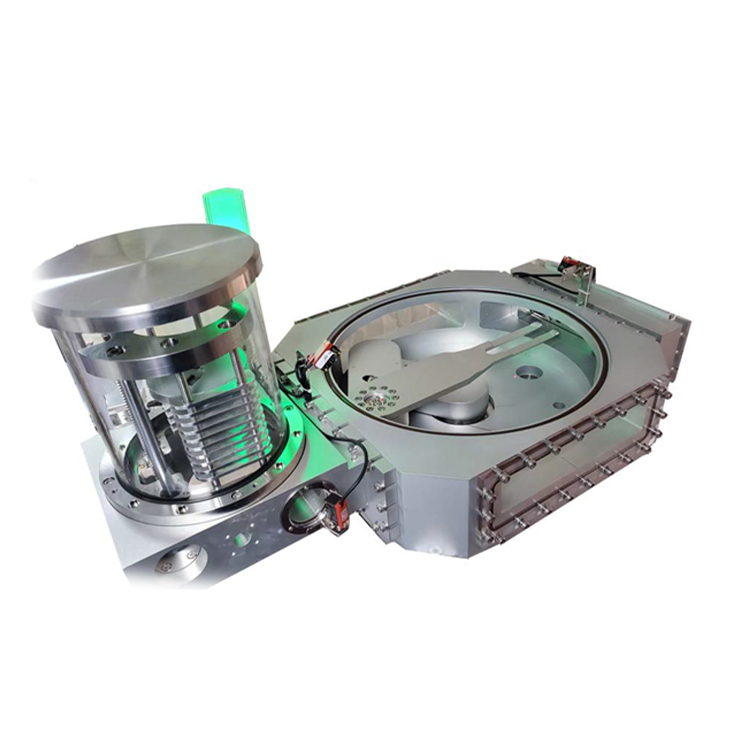

Sample Table | Overall dimensions | Φ 360 mm |

Adjustable RPM | 1-20rpm adjustable |

Magneto-c ontrolled target gun | Target plane | Circular plane target |

Sputtering vacuum | 0.1Pa to 3Pa |

Target diameter | 100 to 101.6mm |

Target thickness | 3mm |

Insulation voltage | >2000V |

Cable specifications | SL-16 |

| Target head temperature | ≦ 65 ℃ |

Vacuum chamber | Inner wall treatment | Electrolytic polishing |

Cavity size | Φ500mm x 500mm |

Cavity material | 304 stainless steel |

Viewing window | Quartz window, φ100mm diameter |

Opening method | Side opening |

Gas control | Flow control | Mass flowmeter, measuring range 0 ~ 100SCCM |

Gas type | Argon, nitrogen, oxygen and other gases are available |

Regulator Valve Types | Solenoid Regulator |

Static state of regulator valve | Normal close |

Measuring linearity | Plus or minus 1.5% F.S |

Measurement repetition accuracy | Plus or minus 0.2% F.S |

Measure response time | ≤8 seconds (T95) |

Range of working pressure difference | 0.3 MPa |

Pressure resistant body | 3MPa |

Working ambient temperature | (5 ~ 45) ℃ |

Body material | Stainless steel 316L |

Leakage rate of body | 1×10-8Pa.m3/s |

Pipe fittings | 1/4 "jacketed joints |

Input/output signals | 0 to 5V |

Power supply | ±15V (±5%) (+15V 50mA, -15V 200mA) |

Overall dimensions mm | 130 (W) x 102 (H) x 28 (H) |

Communication interface | RS485 MODBUS protocol |

DC power supply | Power supply | 1500W |

Film thickness measureme nt | Power requirements | DC:5V (±10%) Maximum current 400mA |

Resolution | ±0.03Hz(5-6MHz), 0.0136A/measurement (aluminum) |

Measurement accuracy | ±0.5% thickness +1 count |

Measurement cycle | 100mS ~ 1S/ time (can be set) |

Measuring range | 500,000 A (aluminum) |

Crystal frequency | 6MHz |

Communication interface | RS-232/485 serial interface |

Display bits | 8-bit LED display |

Molecular pump | Molecular pumping speed | 1200L/S |

Rated speed | 24000rpm |

Vibration value | ≦ 0.1 um |

Start-up time | 5min |

Downtime | 7min |

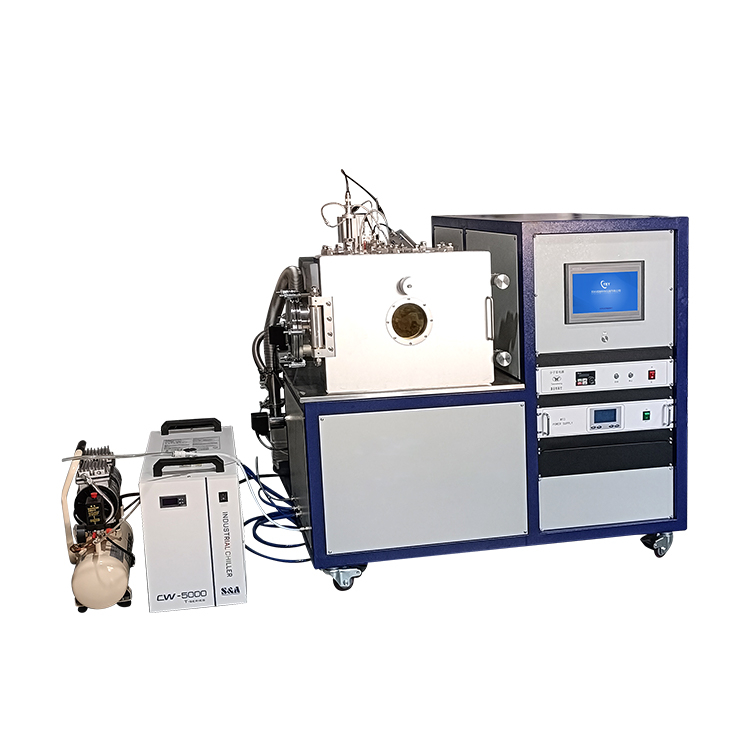

Cooling method | Water cooling + air cooling |

Cooling water temperature | ≦37℃ |

Cooling water flow rate | 1L/min |

Mounting direction | Vertical ±5。 |

Air extraction interface | 150CF |

Exhaust port | KF40 |

Front pump | Pumping rate | VRD-16 |

Ultimate vacuum | 1Pa |

Power supply | AC:220V/50Hz |

Motor power | 400W |

Noise | ≦56db |

Air extraction interface | KF40 |

Exhaust port | KF25 |

Valve | Gate valve | A gate valve is arranged between the vacuum chamber and the molecular pump |

Cut-off valve | A cut-off valve is installed between the molecular pump and the front stage |

Side drain valve | A side drain valve is installed between the vacuum chamber and the front stage |

Bleeder valve | An electromagnetic bleeder valve is installed on the vacuum chamber |

Ultimate vacuum of the whole machine | ≦5X10-4Pa |

Test target | 1 piece of nickel target 4 inches in diameter and 3mm thick |