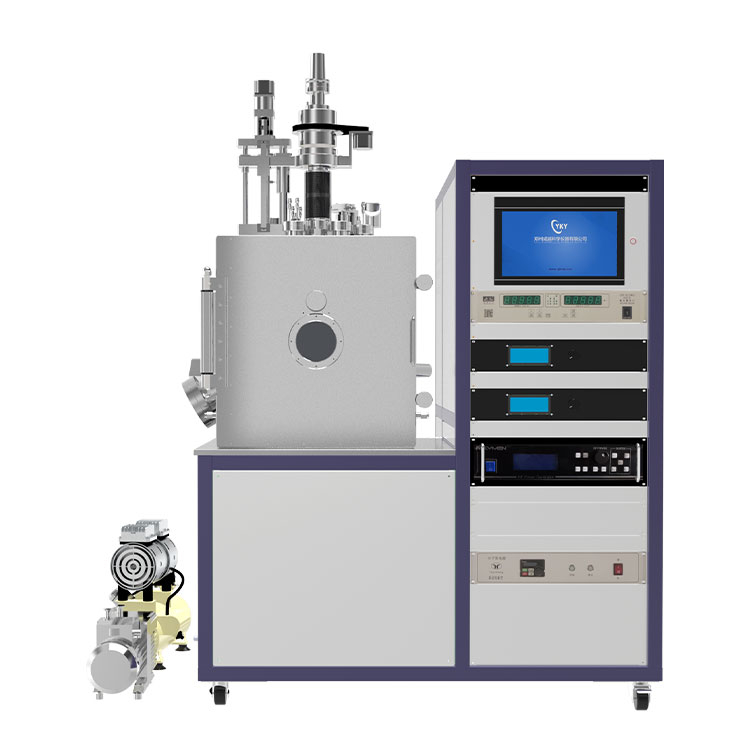

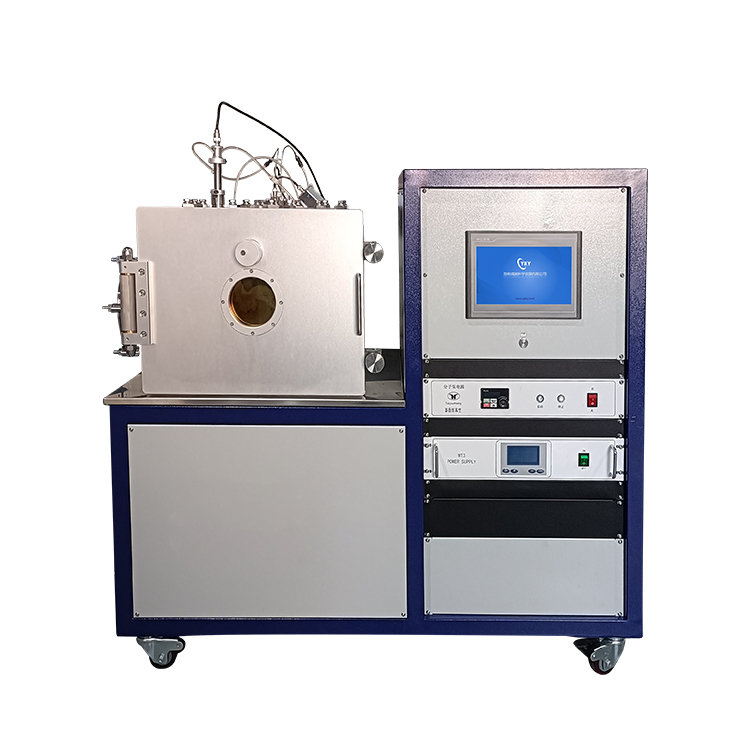

four target magnetron sputtering coater instrument for conductive film

The four target magnetron sputtering coating instrument can be used to prepare single or multi- layer ferroelectric film, conductive film, alloy film, semiconductor film, ceramic film, dielectric film, optical film, oxide film, hard film, polytetrafluoroethylene film

Four-target magnetron sputtering coater is a cost-effective magnetron sputtering coater independently developed by our company, which has the characteristics of standardization, modularization and customization. The magnetron target has a choice of 1 "2", customers can choose according to the size of the plated substrate; The power supply is 500W DC power supply and 500W RF power supply, DC power supply can be used for the preparation of metal film, RF power supply can be used for the preparation of non-metal film, three targets can meet the needs of multi-layer or multiple coatings. If customers have other coating needs, you can customize other RF power supply and pulse power supply, each type of power supply has a variety of specifications from 300W to 1000W.

The coating instrument is equipped with two high-precision mass flowmeters. If customers have other needs, they can customize the gas path of up to four mass flowmeters to meet the needs of complex gas environment construction; The instrument is equipped with advanced turbomolecular pump group, the limit vacuum can reach 1.0E-5Pa, and other types of molecular pumps are available for purchase. The gas route of the molecular pump is controlled by multiple solenoid valves, which can realize that the chamber can be opened and the sample can be taken out without the pump, which greatly improves your work efficiency. This product can be selected as an industrial computer to control the system, in the computer program can achieve the control of the vacuum pump group, sputtering power supply control and other most functions, can further improve your experimental efficiency.

The four target magnetron sputtering coating instrument can be used to prepare single or multi- layer ferroelectric film, conductive film, alloy film, semiconductor film, ceramic film, dielectric film, optical film, oxide film, hard film, polytetrafluoroethylene film and so on. Compared with similar equipment, the three-target magnetron sputtering coateris not only widely used, but also has the advantages of small size and easy operation. It is an ideal equipment for preparing material films in the laboratory

Coating vacuum system | Vacuum assembly | 60m3/h mechanical pump and KYKY1600L molecular pump to form the pumping system and equipped with high- precision composite vacuum gauge to measure and monitor the vacuum degree in realtime; |

Pumping time | After the system is exposed to the atmosphere for a short time and filled with dry nitrogen, then pumping begins. The vacuum degree is less than 5×10-4Pa within 30 minutes, and the vacuum degree is less than 5Pa after the system stops pumping and shuts down for 12 hours; |

Ultimate vacuum | ≤6×10-5Pa |

Valve assembly | Pre-extraction valve DN40, electric main valve CF200, DN16 vent valve, DN40 solenoid valve and various vacuum lines, etc. (the above valves are pneumatic or electric) |

Vacuum automatic constant pressure | The equipment can quickly reach the high vacuum, and can be automatically adjusted in real time when the required vacuum degree is reached after the process air intake, so as to maintain a stable vacuum degree, reduce the process to a high degree, and ensure the repeatability of the prepared sample. |

Magnetron sputtering generation and control reaction system | Coating chamber limit vacuum | ≤6×10-5Pa; System vacuum leak detection rate: ≤8.0×10-7 Pa.l/S |

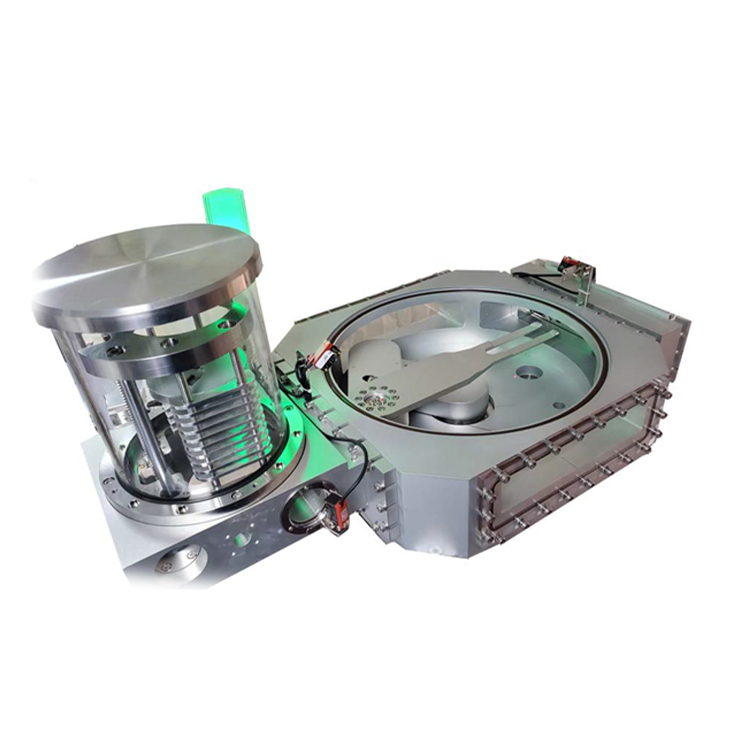

Vacuum chamber size | 500 x 500 x 420mm, |

Gas type | Argon, nitrogen, hydrogen, oxygen |

Substrate size as well as functional components | Substrate sizes of Φ4 inches (compatible with small sizes) can be placed; Substrate rotation range 5~60 RPM adjustable; Substrate heating temperature 600±1℃, controlled by thermocouple closed-loop feedback (i.e. PID temperature control) |

Cooling method | Water cooling |

Sputter deposition and control system | Control system | PLC+ PC software coating machine control system |

Constant pressure working intake | of air | Use a thin film vacuum gauge for measurement |

Measuring range | 3 Pa 0.013 Pa |

Target number | size, | 4 2-inch sputter targets |

Target Spacing | The four targets are sputtered vertically upward, and the distance between the target and the sample is adjustable |

Power Supply | 2 sets of 500W RF sputtering power supply (automatic matching), 2 sets of 500W DC sputtering power supply, 1 set of 500W bias power supply (improve the density and uniformity of the film layer, and have sputtering cleaning function) |

Process air Intake assembly | 2 way MFC mass flow meter controls gas flow (0- 100SCCM, 0-200 SCCM), accurate to 0.1 sccm adjustable |

Evenness | The uniformity of the inner membrane thickness of the 4- inch diameter wafer sample is less than 3%, and the error between the center point and the edge thickness is less than 3% |

Other | Supply voltage | AC220V,50Hz |

Overall dimensions | 600mm X 650mm X 1280mm |

Machine weight | 350kg |

Machine power | 4KW |