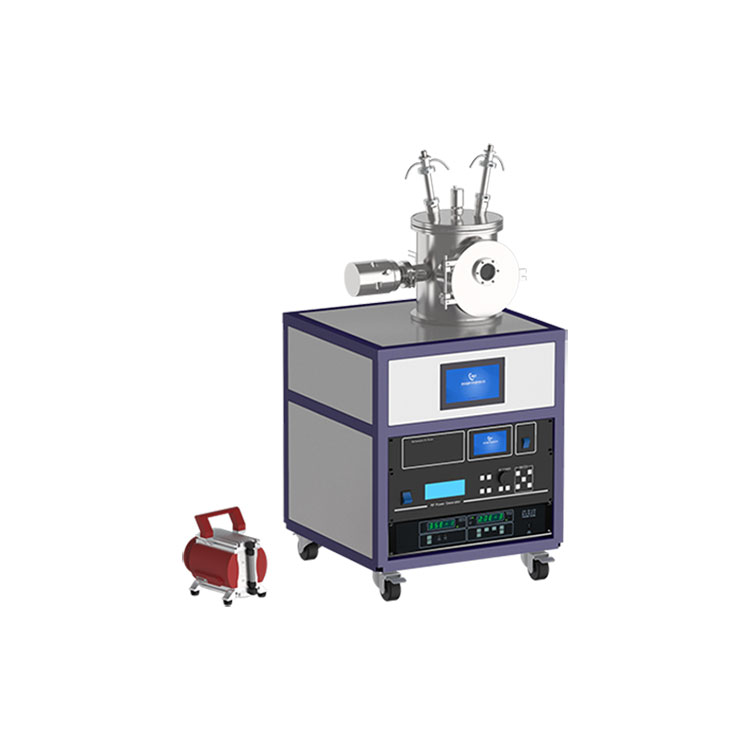

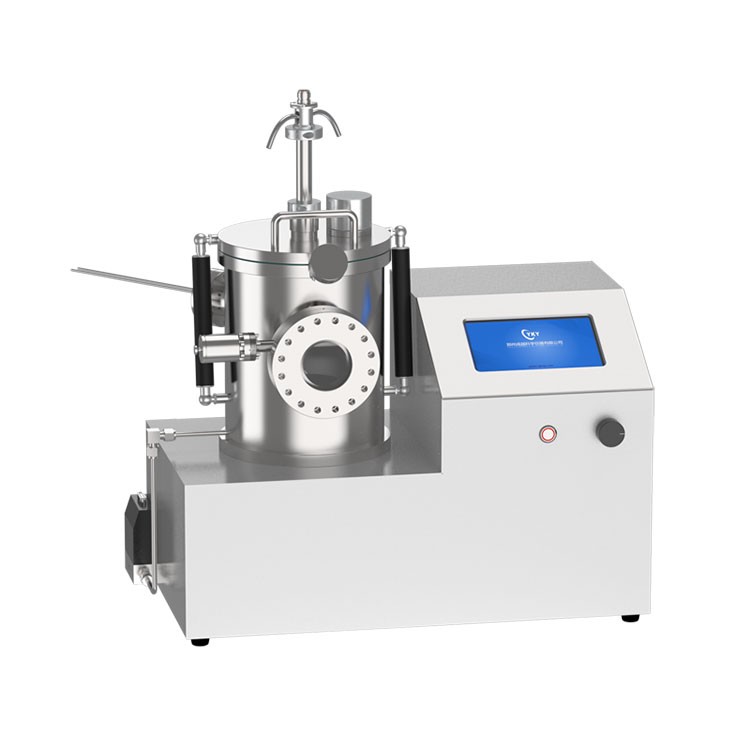

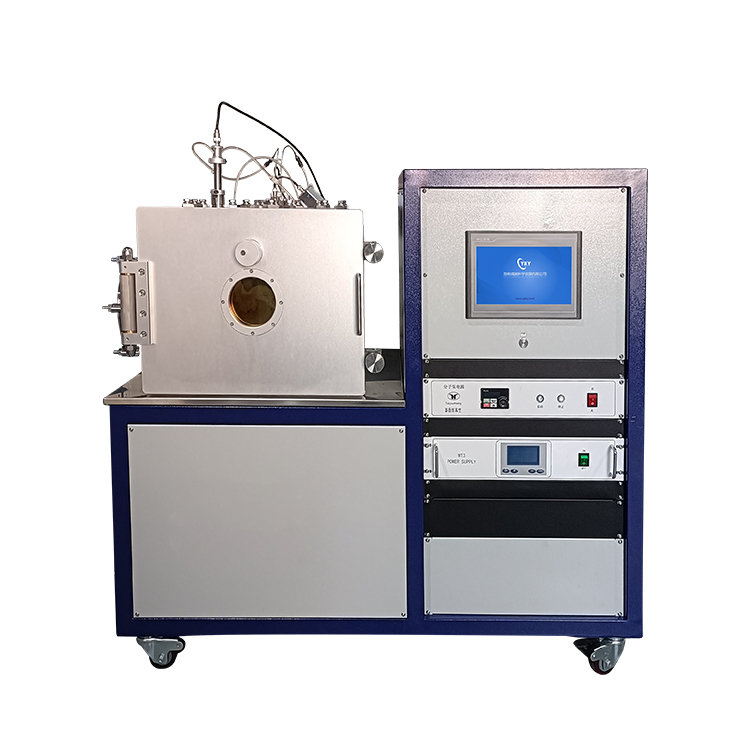

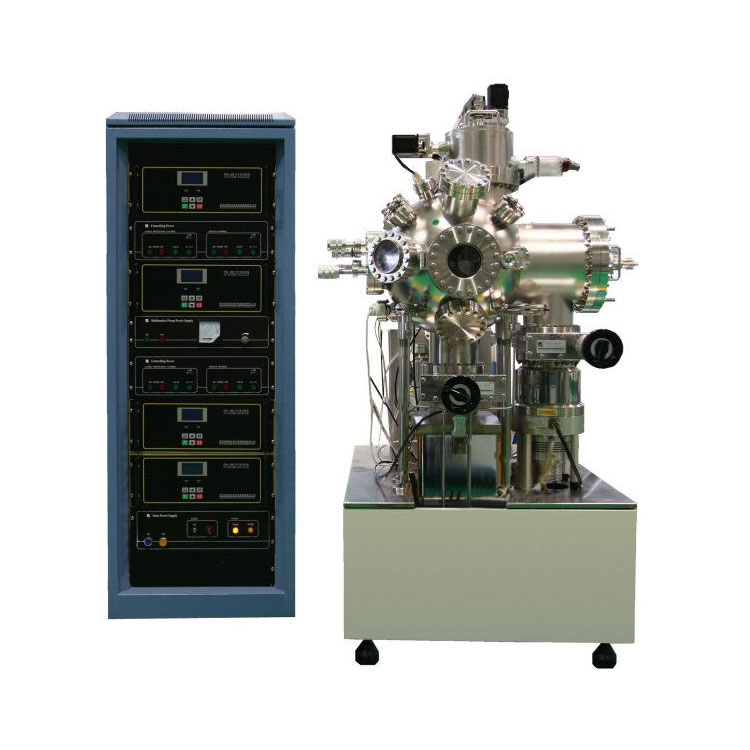

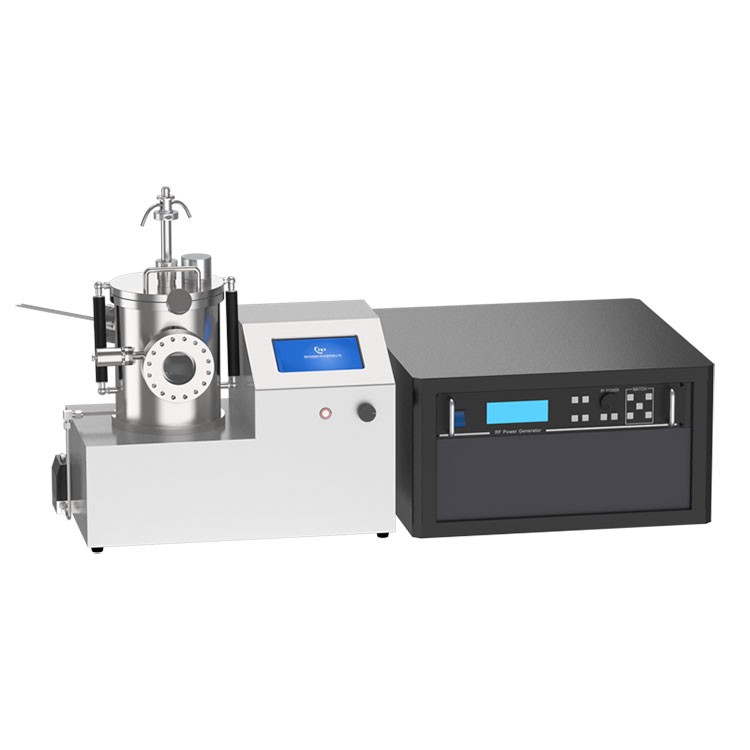

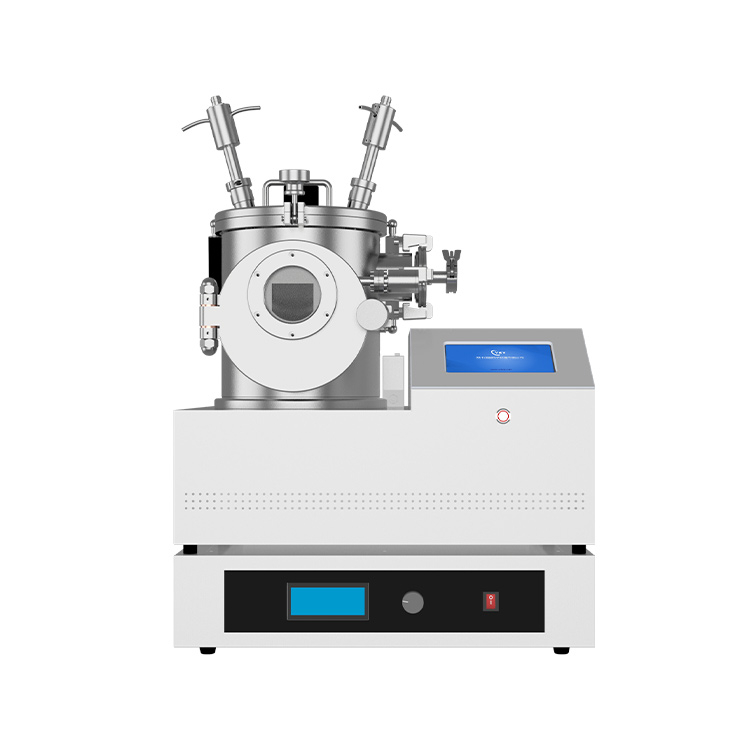

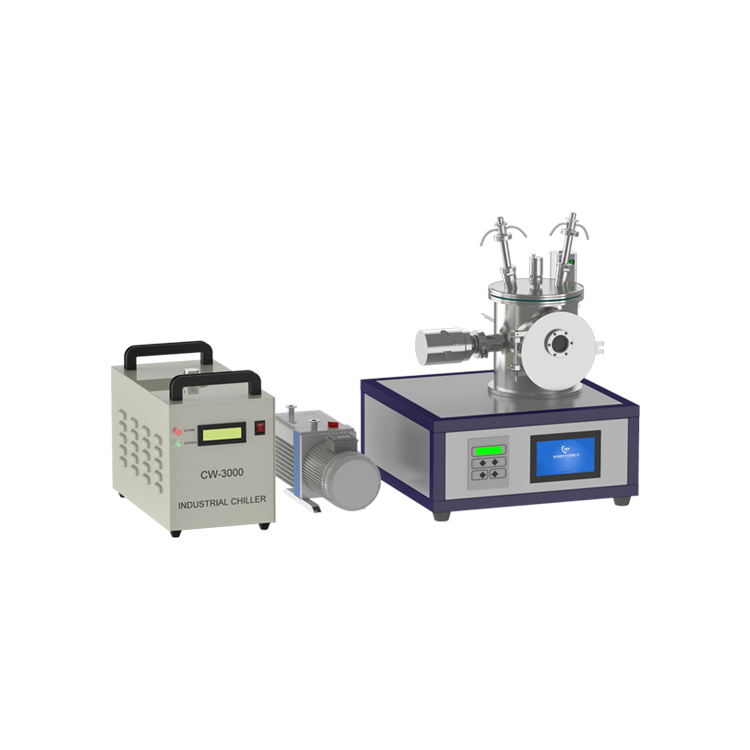

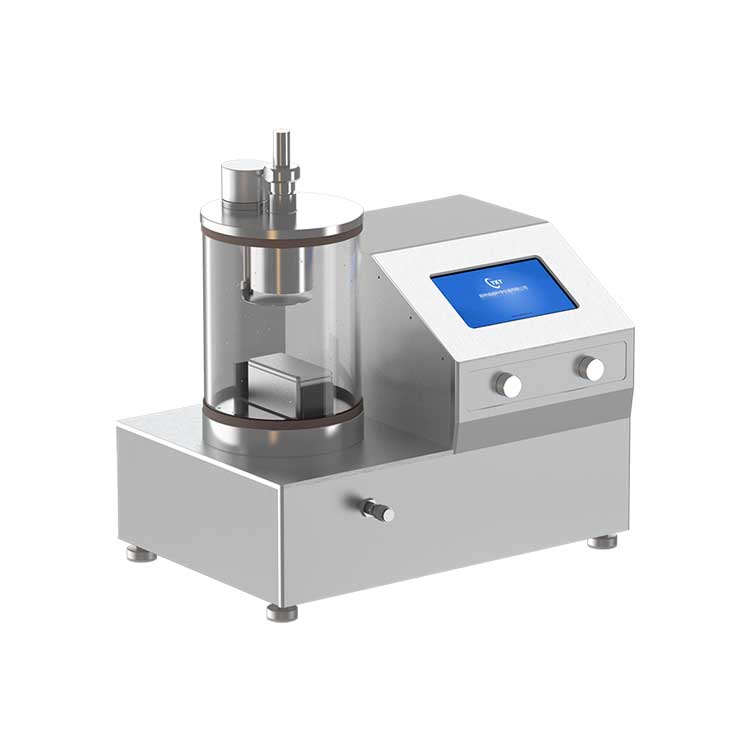

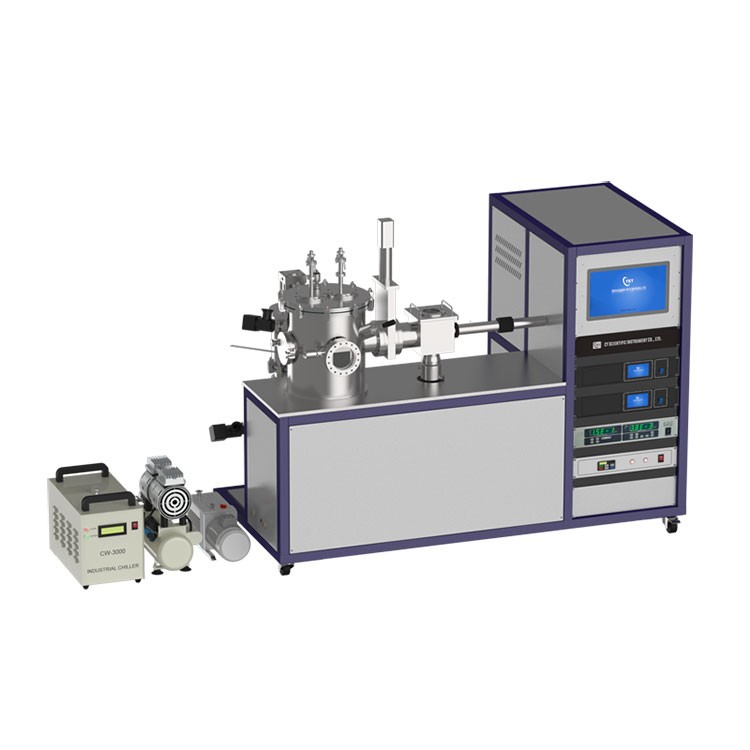

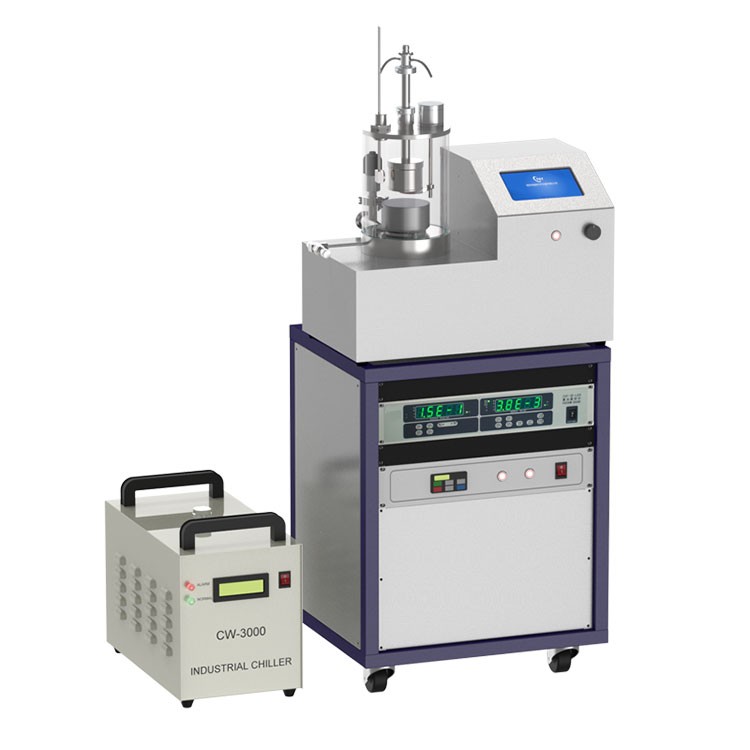

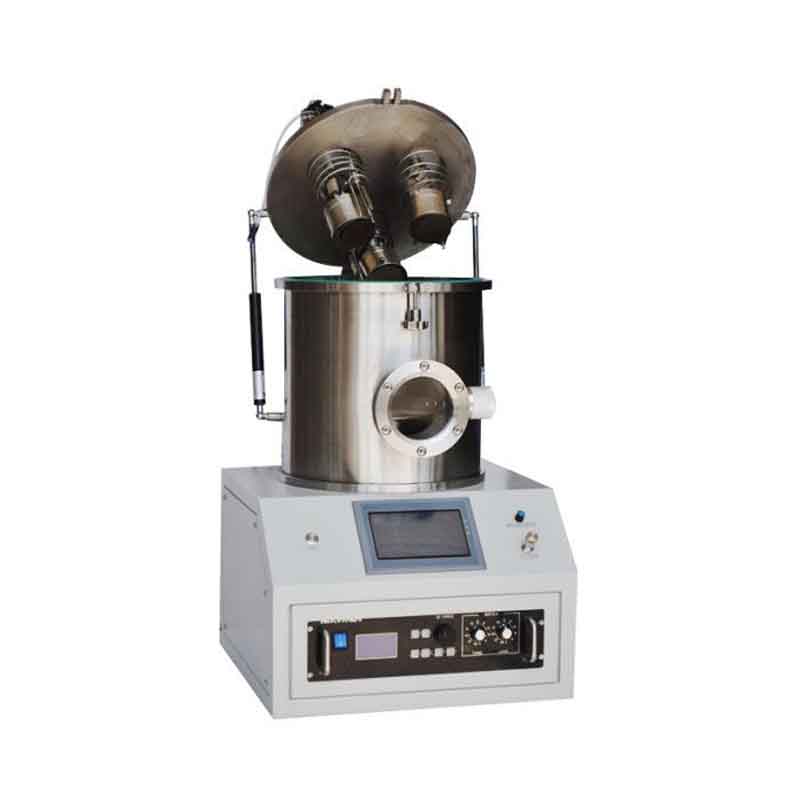

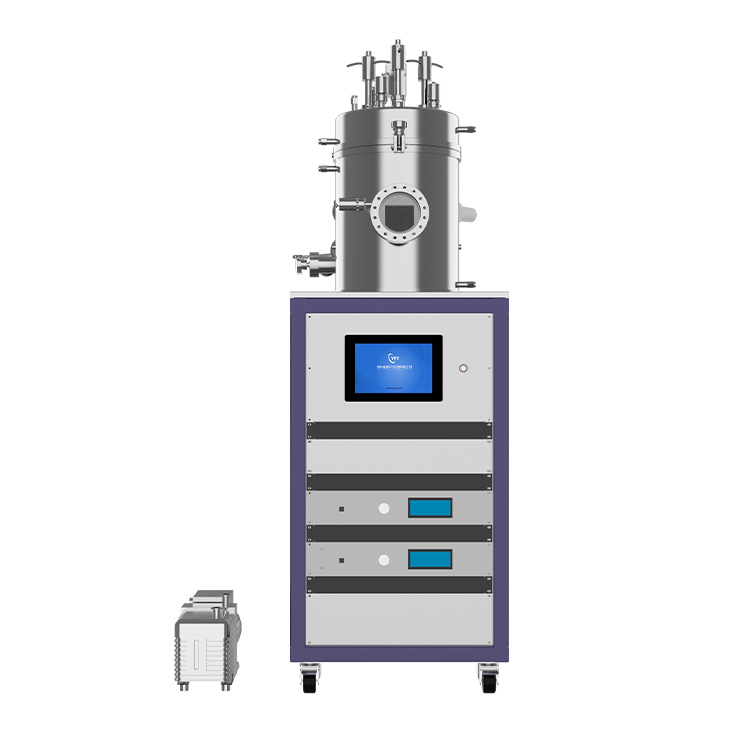

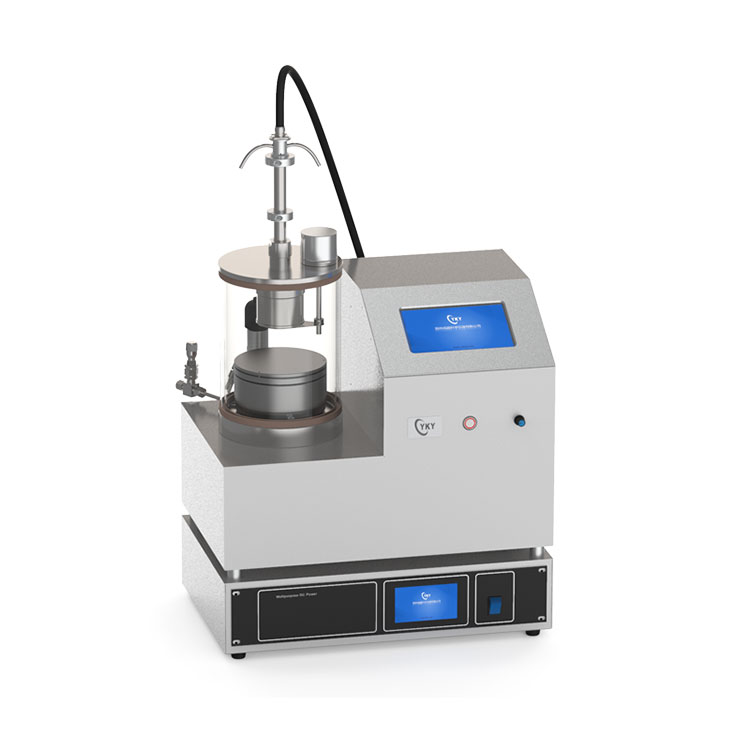

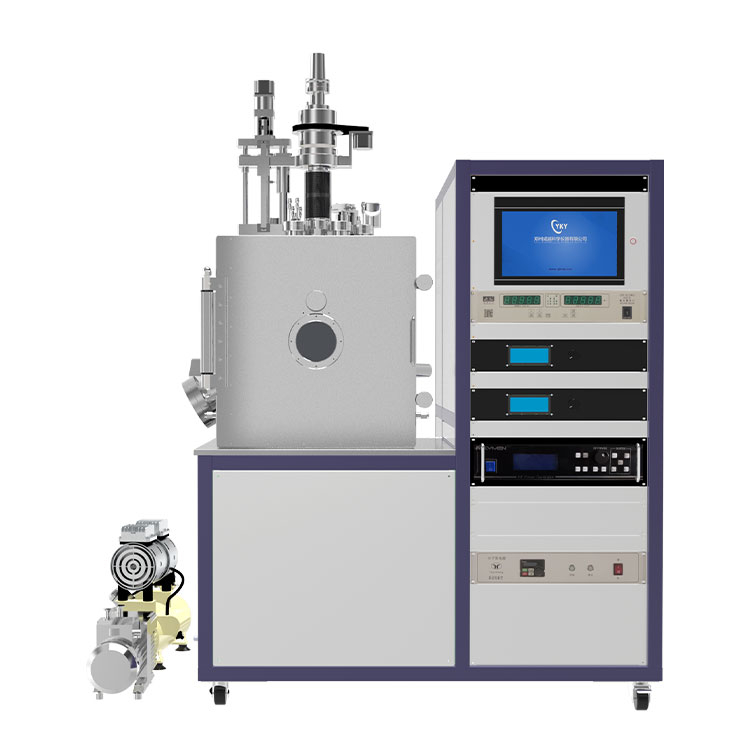

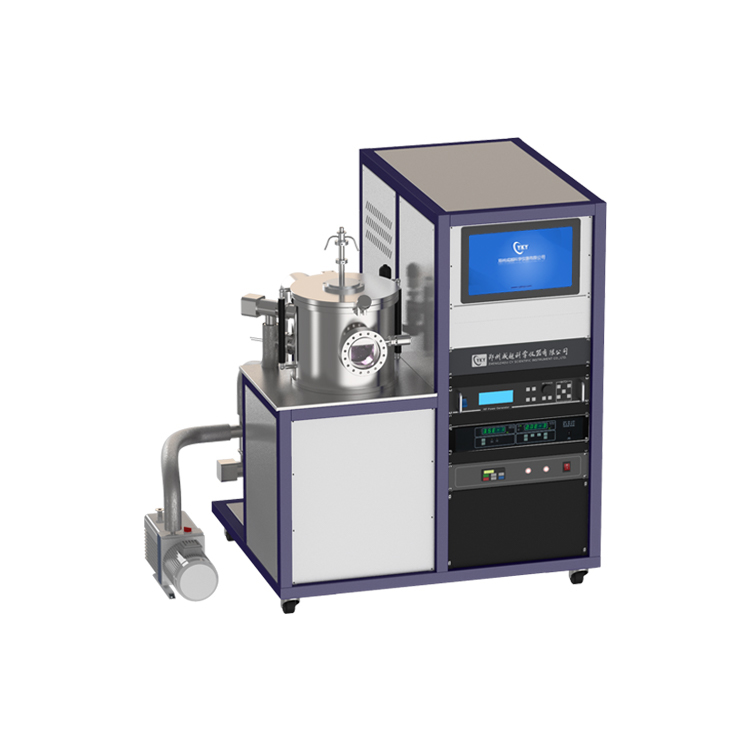

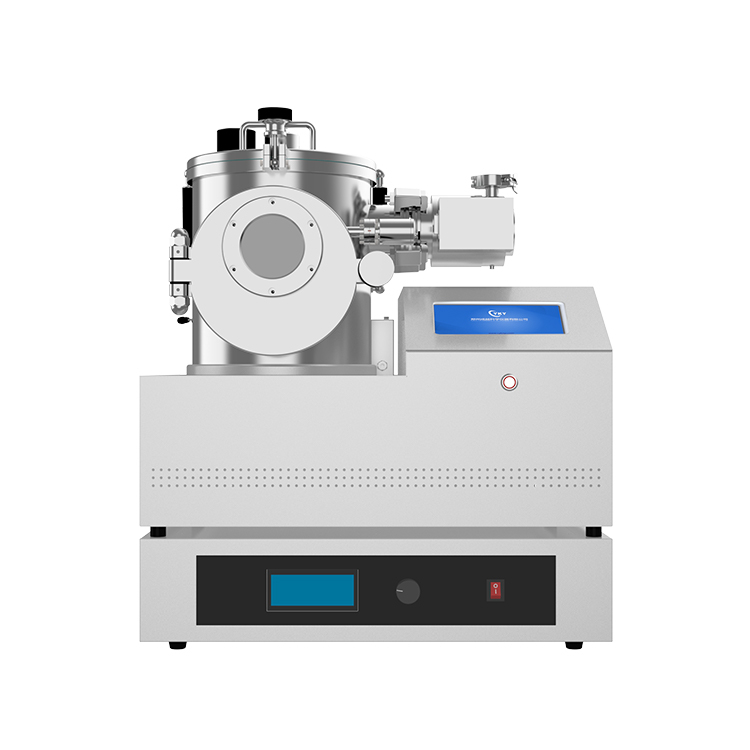

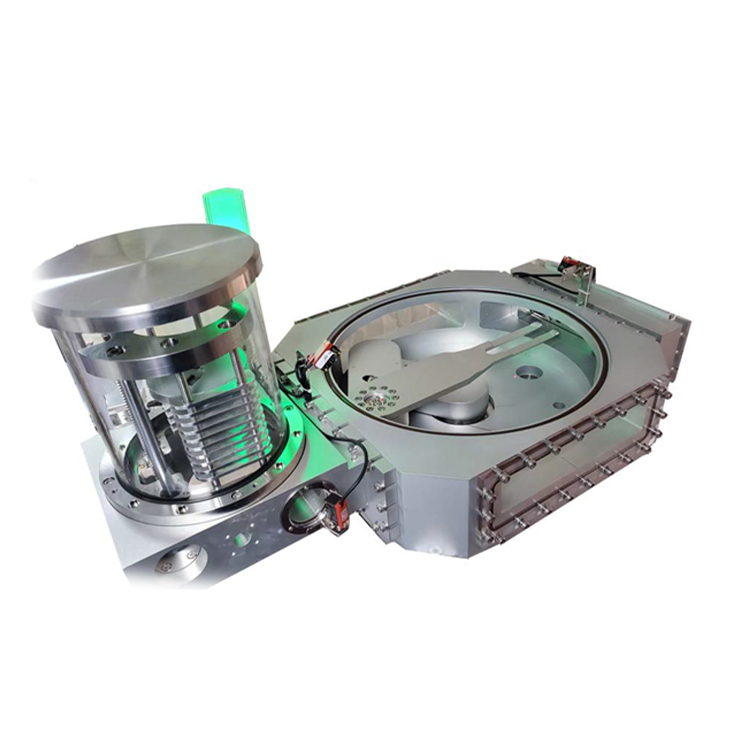

Programmable single chamber magnetron sputtering coater is a single-chamber structure, mainly composed of sputtering vacuum chamber, magnetron sputtering target, ion bombardment, revolution substrate, optical heating system, sputtering power supply, working gas path, vacuum acquisition system, installation machine, vacuum measurement, water cooling, alarm system and control system,etc.

The system is controlled by IPC and PLC, with two modes of automatic and manual control. In addition to put the sample, all other processes are realized on the touch screen. It provides man-machine operation interface such as vacuum system, sputtering process setting, filling and venting system, etc. On the IPC, you can set parameters through the formula, to implement the procedure process and equipment parameter Settings.

Programmable single chamber magnetron sputtering coater

Sputtering chamber vacuum limit | ≤8.0×10-6Pa |

Vacuum recovery time | The system was pumped from atmosphere to 1.0×10-3 Pa within 15minutes |

Uniformity | Film thickness nonuniformity≤±5%; nonuniformity between the slices≤±5%; Inhomogeneity between batches≤±5% |

Sputtering vacuum chamber | The cylindrical structure, size 800mmx250mm |

Magnetron sputtering system | Permanent magnet target 4, target size 6 inches; One imported power supply (rf or dc pulse optional); Sputtering rate: 0.5 ~ 5 angstrom per second (target Al) |

Revolution base plate | 6 inches 6 pieces (4 inches 12 pieces or 3 inches 16 pieces); The substrate revolution is 3~15 revolution/min, continuously adjustable, and the common rotation composite worktable is optional |

Light heating system | Sample heating temperature: room temperature to 250 ℃, continuous adjustable; Substrate temperature nonuniformity: ≤±10℃; Temperature control method is PID automatic temperature control and digital display, equipped with imported temperature control meter. |

Working gas channel | 2 channel mass flow controller (MFC) |

Gas pump composition | Cryopump (imported), Roots dry pump set, air gate valve (imported), pipes |

Vacuum measurement | System vacuum, working vacuum and backing vacuum was precisely measured by 2 vacuum gauges (imported); the vacuum degree can be displayed visually on the touch screen of industrial computer; the vacuum degree of the sputtering coating process can be monitored accurately. |

Control system | The entire system can be controlled by IPC (touch screen) and PLC (imported) |

Floor Space | Main set | 1500×1000mm2 |

electric control cabinet | 700×700mm2(one) |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.