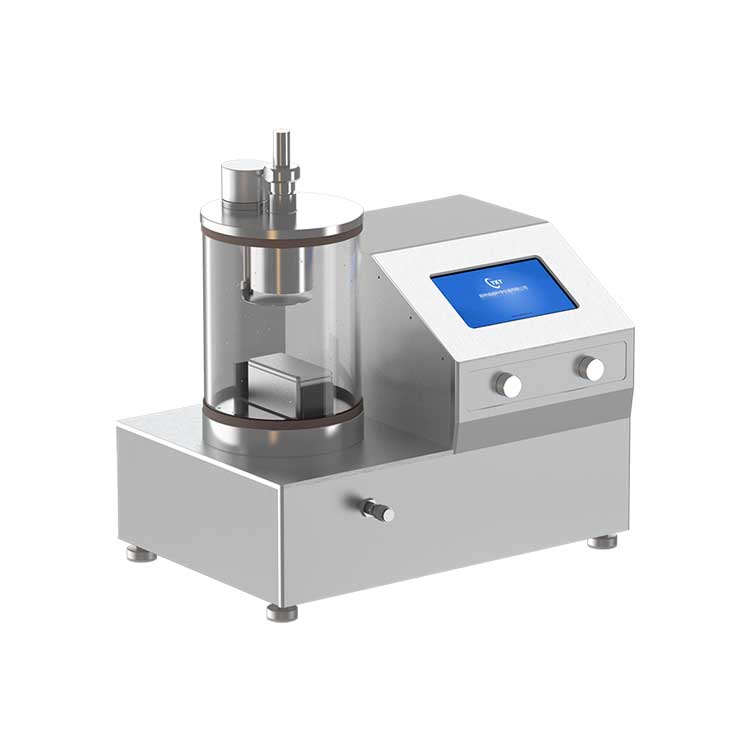

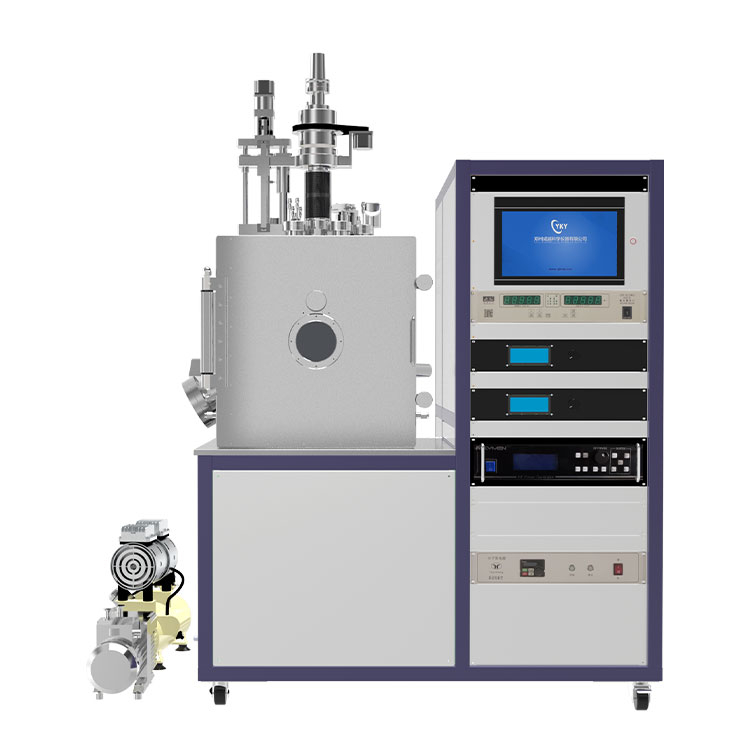

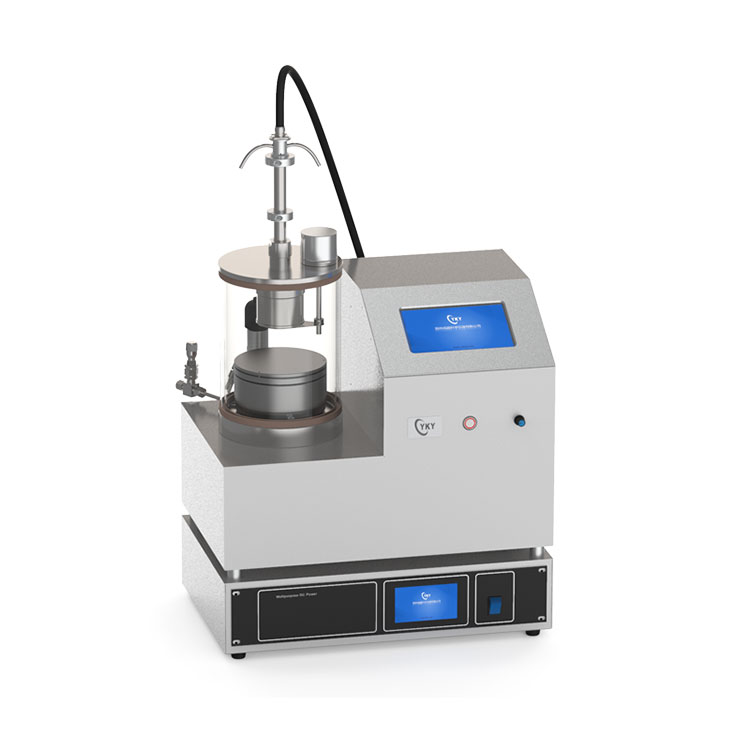

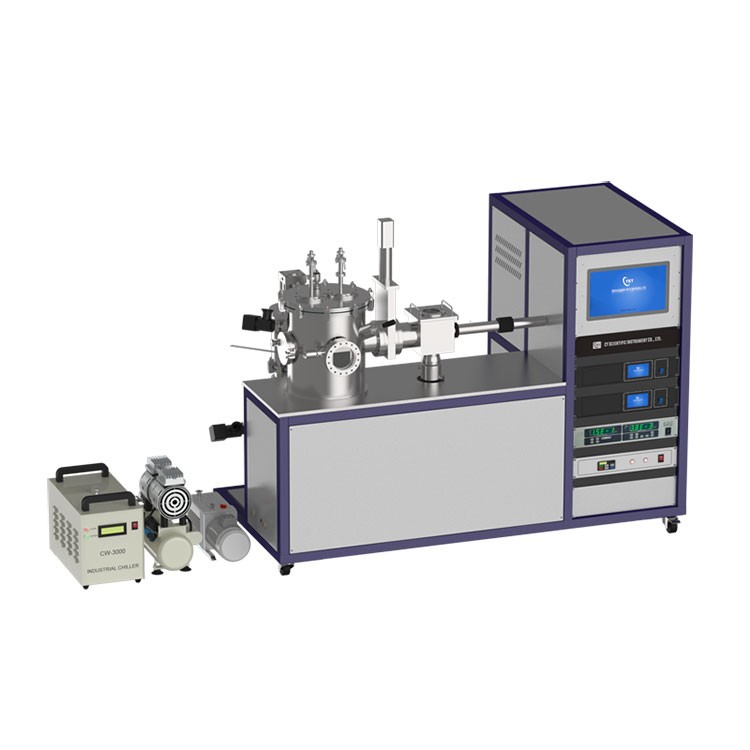

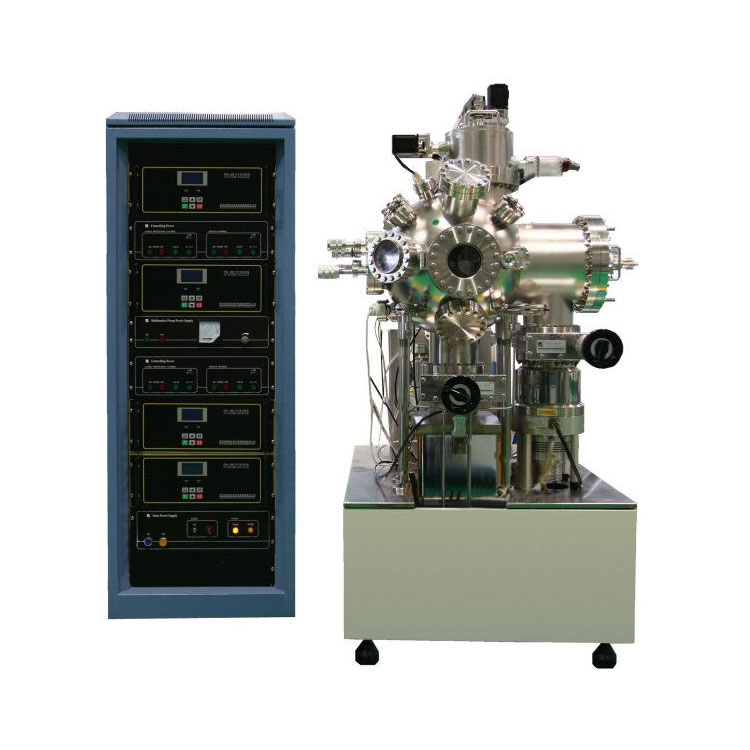

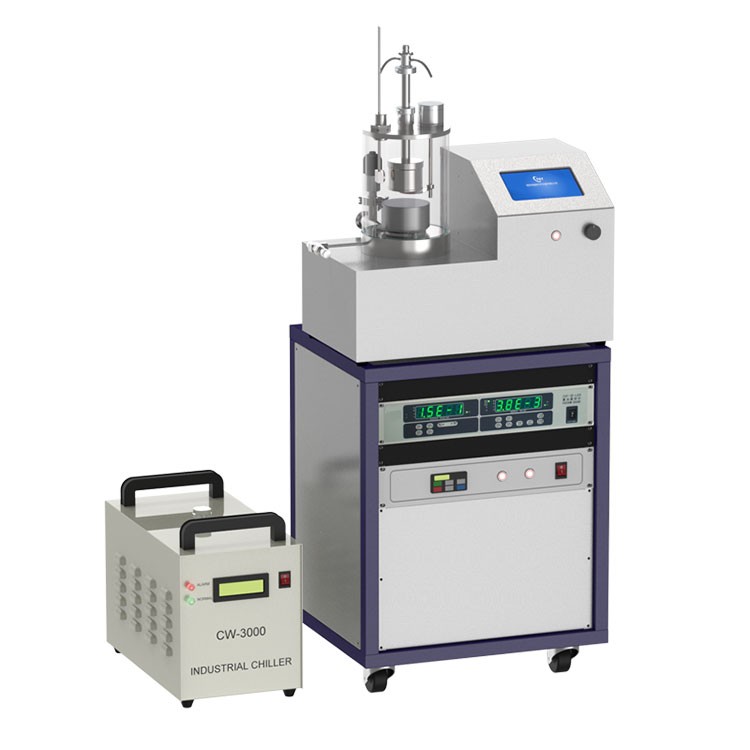

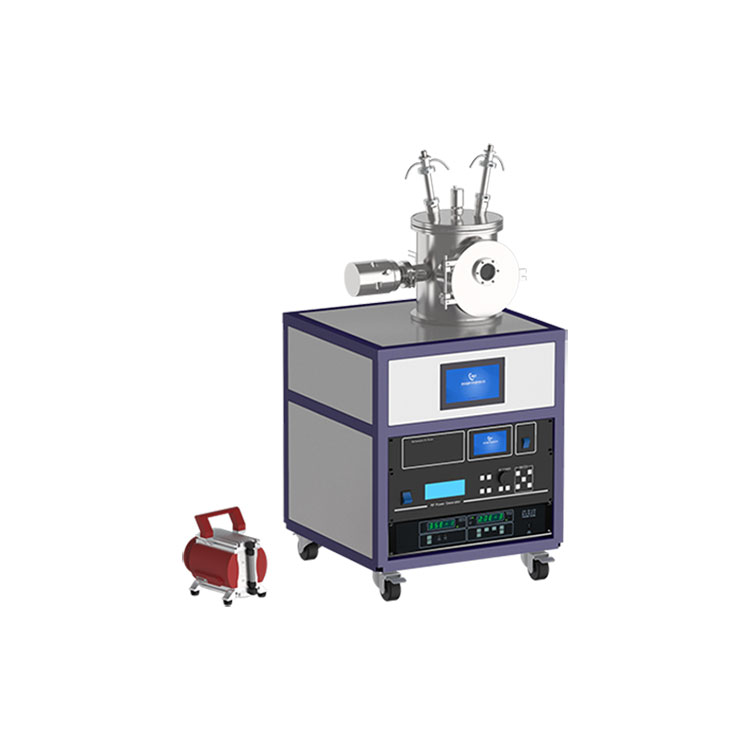

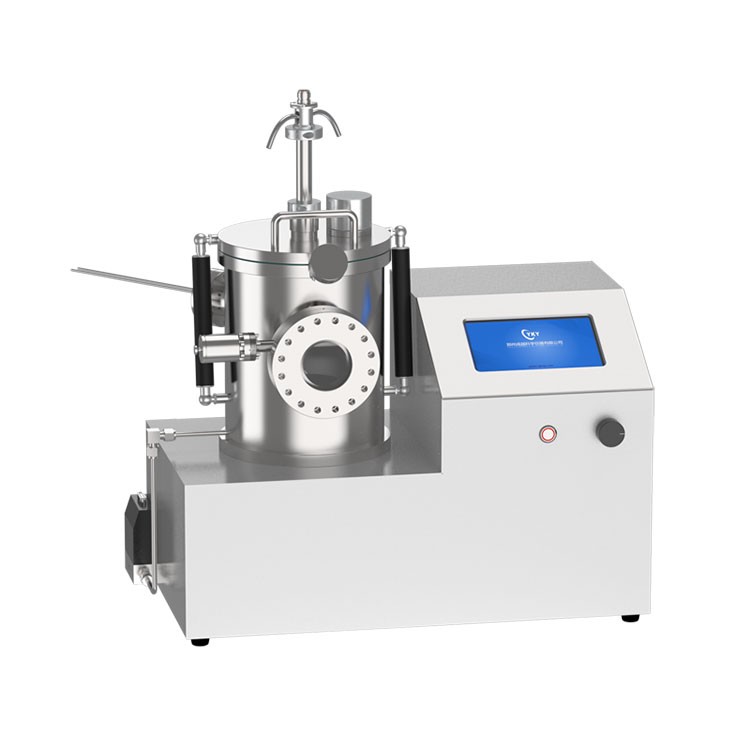

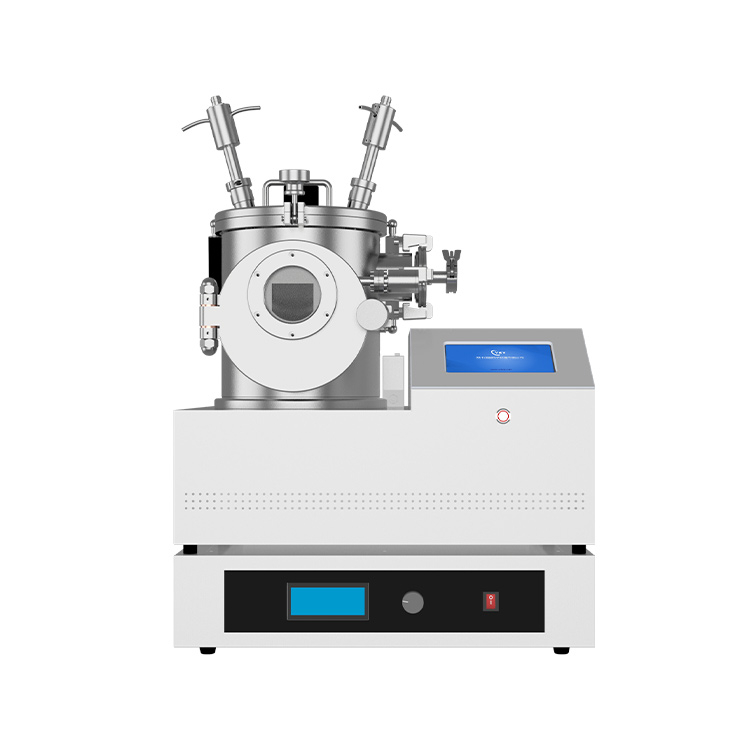

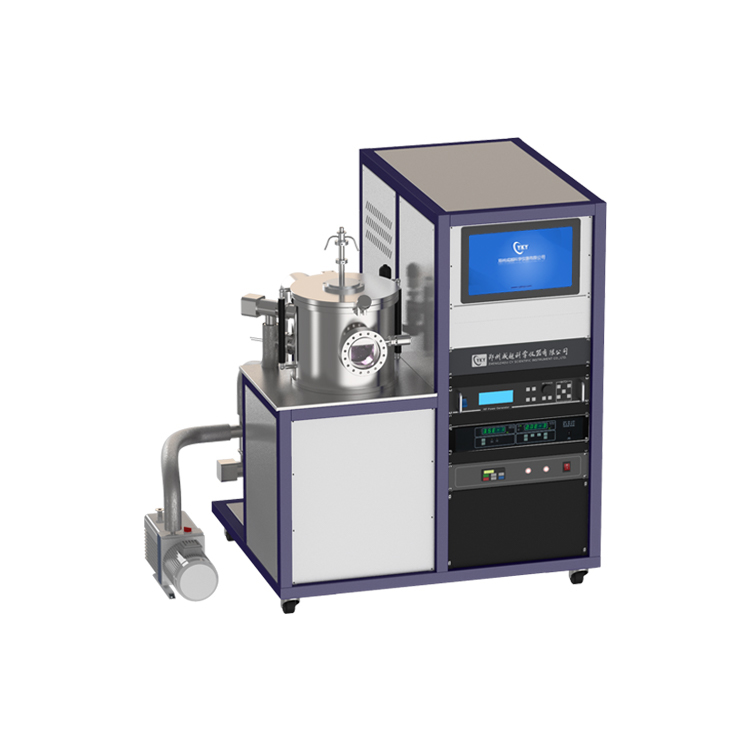

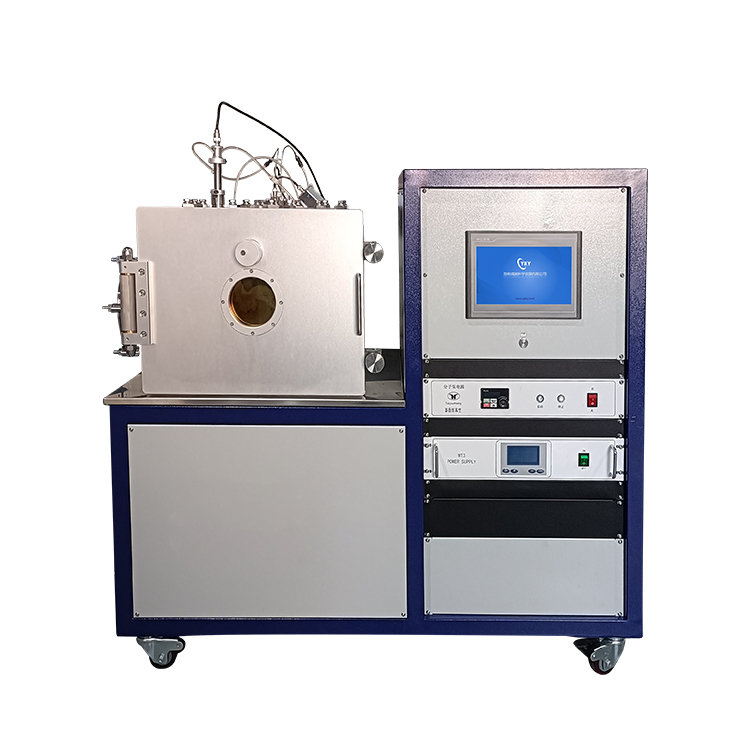

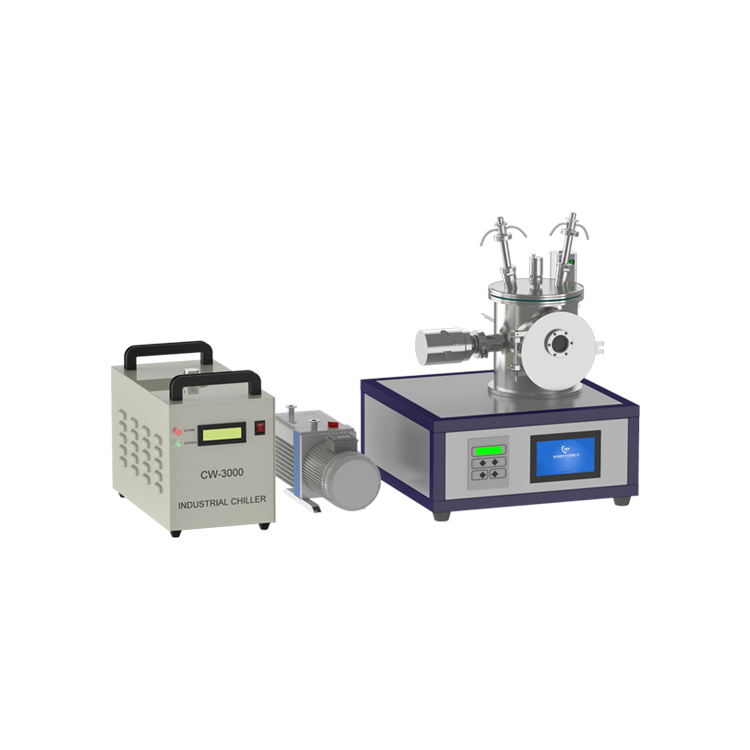

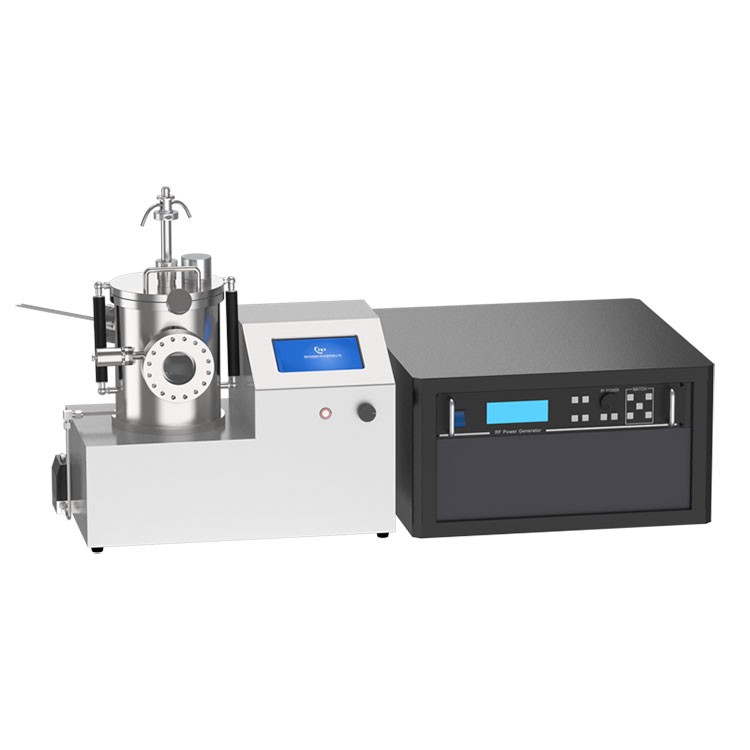

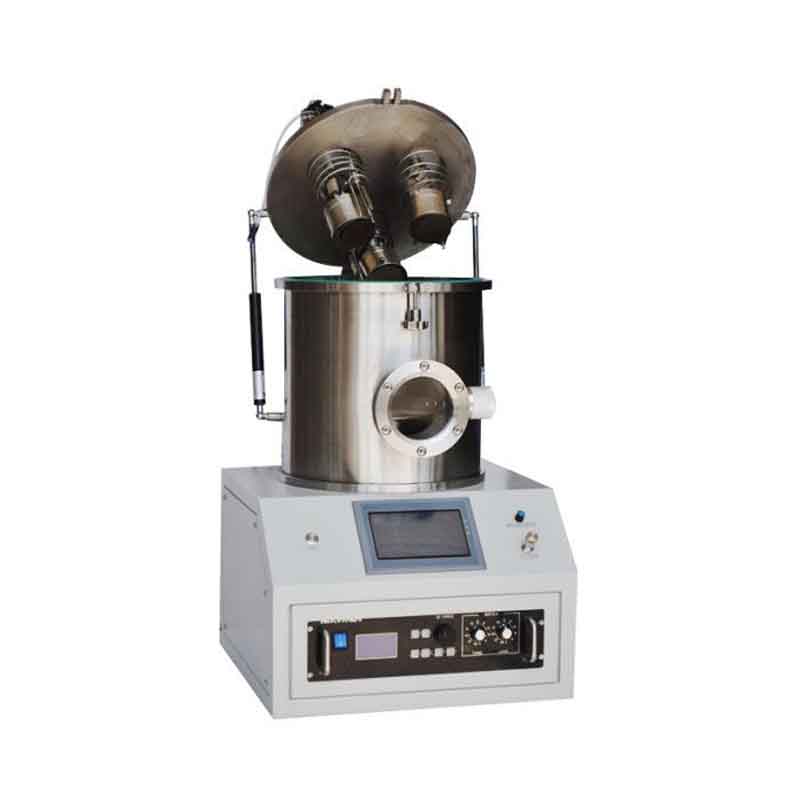

The magnetron sputtering/vacuum evaporation composite coating equipment combines magnetron sputtering technology and vacuum evaporation technology in one coating equipment. In this device, magnetron sputtering cathode glow discharge is used to sputter the target atoms and partially ionize and deposit them on the substrate to form a film, and at the same time, the metal plating material can be melted in a vacuum by resistance heating and vaporized and then deposited on the substrate to form a film. This increases the utility and flexibility of the device. The equipment is used for metallization of plastic surface such as mobile phone case and deposition of non-conductive film and electromagnetic shielding film.

The magnetron sputtering/vacuum evaporation composite coating equipment is equipped with a plasma processing device, a high-efficiency magnetron sputtering cathode and a resistance evaporation device, etc. The deposition rate of this device is fast, the coating adhesion is good, the plating layer is fine and compact, the surface finish is high, the uniformity and consistency is good; the machine realizes full automatic control of coating process, large load, reliable work, high qualification rate, low production cost and green environmental protection.

Magnetron sputtering/vacuum evaporation composite coating equipment application:

The device is widely used in computer casings, mobile phone cases, household appliances and other industries, and can be coated with metal film, alloy film, composite film layer, transparent (translucent) film, non-conductive film, electromagnetic shielding film and the like.

Magnetron sputtering/vacuum evaporation composite coating equipment specifications:

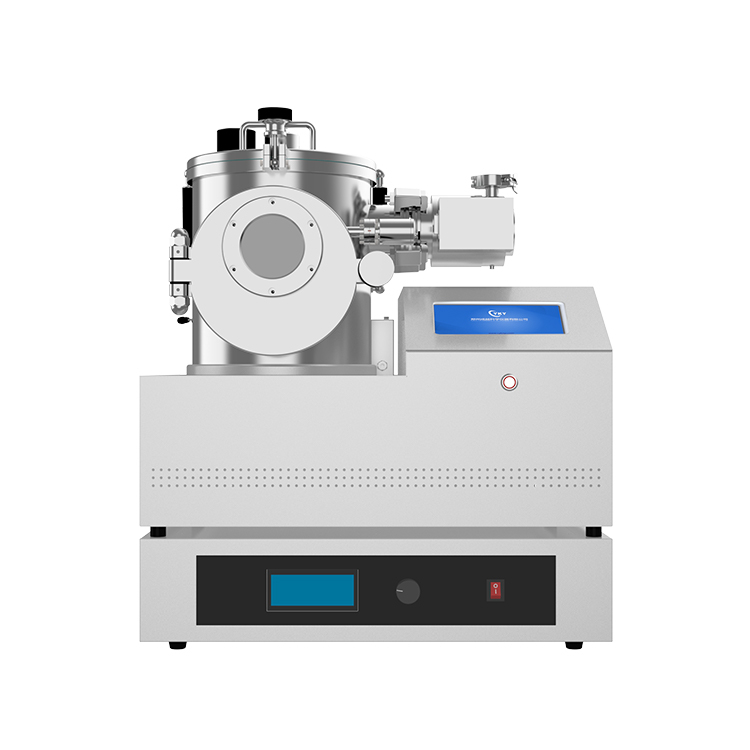

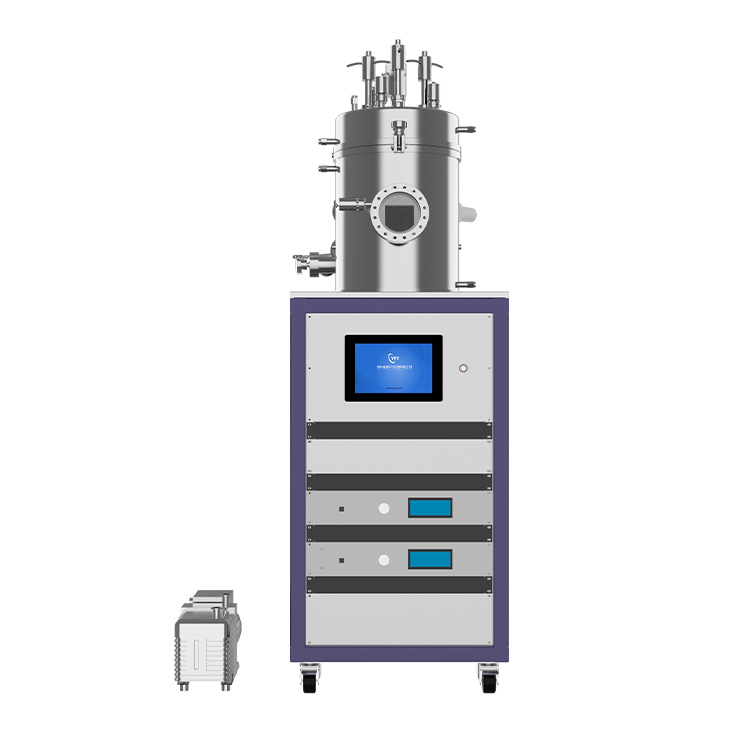

Product Model | Magnetron sputtering/vacuum evaporation composite coating equipment CY-MSE300S-DC |

Sample stage | Size | Φ185mm |

Temperature control accuracy | ±1℃ |

Rotating speed | 1-20rpm adjustable |

Sputter current | 2~20mA |

Sputter voltage | 1000V |

Evaporation source | Tungsten wire basket |

Maximum temperature | 1700℃ |

Precise temperature control | 30-segment lifting and lowering temperature program can be set |

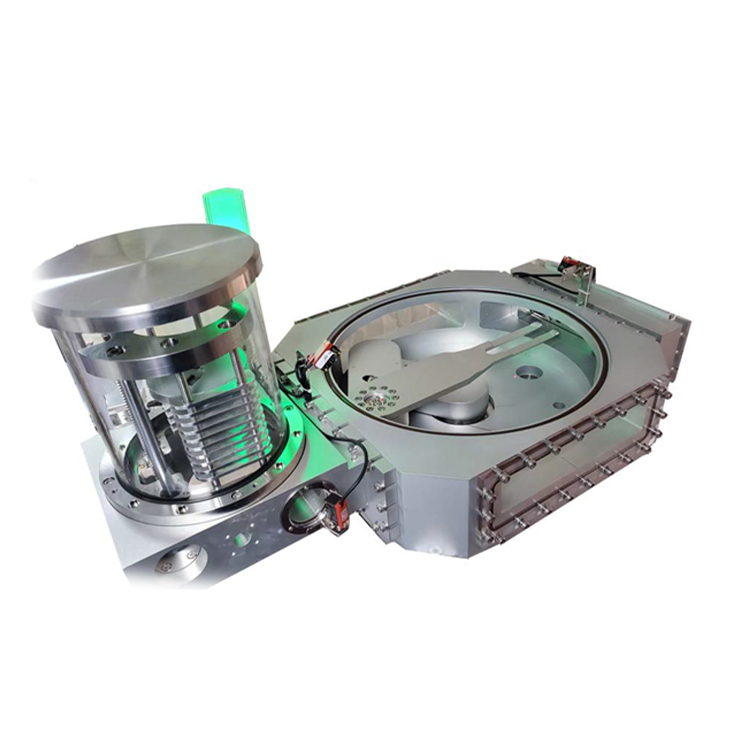

Vacuum chamber | Chamber size | φ300mm × 300mm |

Watch window | φ100mm |

Chamber material | Stainless steel |

Opening method | Top over open |

Film thickness monitor | Monitoring components | Power supply | DC 5V (±10%), maximum current 400mA |

Frequency resolution | ±0.03Hz |

Film thickness resolution | 0.0136Å (aluminum) |

Film thickness accuracy | ±0.5%, depending on process conditions, especially sensor position, material stress, temperature and density |

Measuring speed | 100ms-1s/times, settable |

Measuring range | 500000Å (aluminum) |

Standard sensor crystal | 6MHz |

Computer interface | RS-232/485 serial interface (baud rate 1200, 2400, 4800, 9600, 19200, 38400 can be set, data bit: 8, stop bit: 1, check: none) |

Analog output | 8-bit resolution, PWM pulse width modulated output (open collector or internal 5V output) |

Working environment | Temperature 0-50℃, humidity 5%-85% RH, no condensation beads |

Displayer | Input power | AC 220V±10% |

Output power | DC 5V 3A |

Displayer | 12×2 digital tube and LED |

Communication port | RS-485 (baud rate 1200, 2400, 4800, 9600, 19200, 38400 can be set, data bit: 8 bits, stop bit: 1 bit, parity: none) |

Probes | Applicable wafer frequency | 6MHz |

Applicable wafer size | Φ14mm |

Mounting flange | CF35 |

Cooling water pipe | Φ3mm, length 00mm, 500mm, 1000mm |

Cooling water pressure | <0.3MPa |

Pneumatic baffle pipe | Φ3mm |

Baking temperature | Water supply state <200℃, water-free state flange <100℃ |

Electrical Interface | BCN socket |

Mass flowmeter | 2 channels; measuring range 100sccm; 100sccm (can be customized according to customer needs) |

Vacuum system | Model | CY-GZK103-A |

Pumping interface | KF40 |

Molecular pump | CY-600 |

Exhaust interface | KF16 |

Backing pump | Rotary vane pump |

Vacuum measurement | Compound vacuum gauge |

Ultimate vacuum | 1.0E-5Pa |

Power supply | AC;220V 50/60Hz |

Pumping rate | Molecular pump: 600L/S rotary vane pump: 1.1L/S Comprehensive pumping performance: The vacuum can reach 1.0E-3Pa in 20 minutes. |

Optional accessories | Various targets such as gold, indium, silver, and platinum |

Warranty | One year warranty, lifetime technical support. |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.