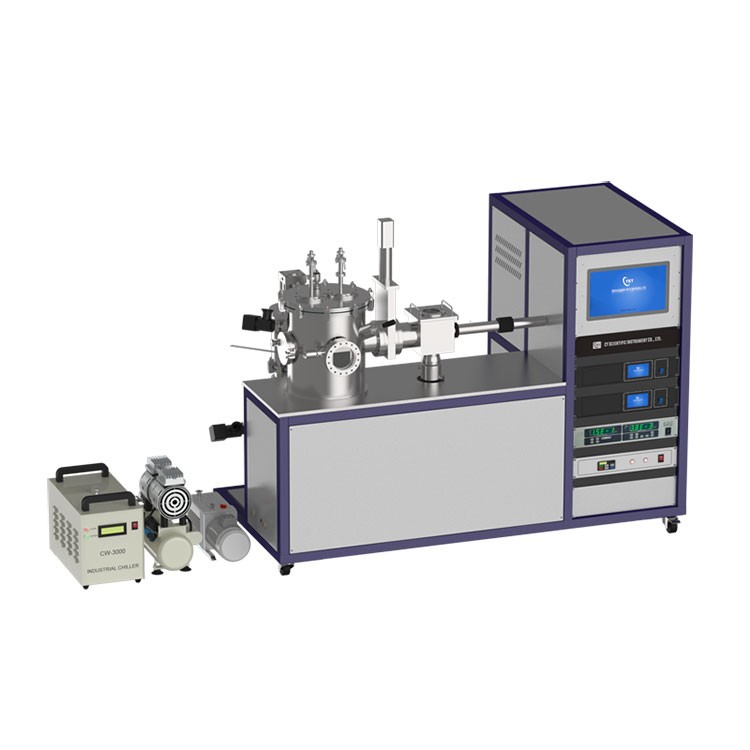

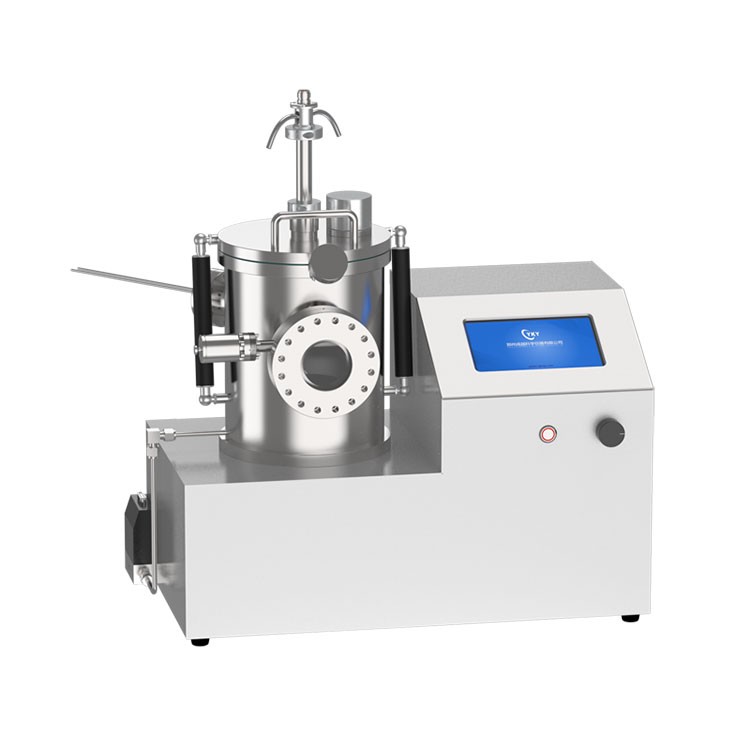

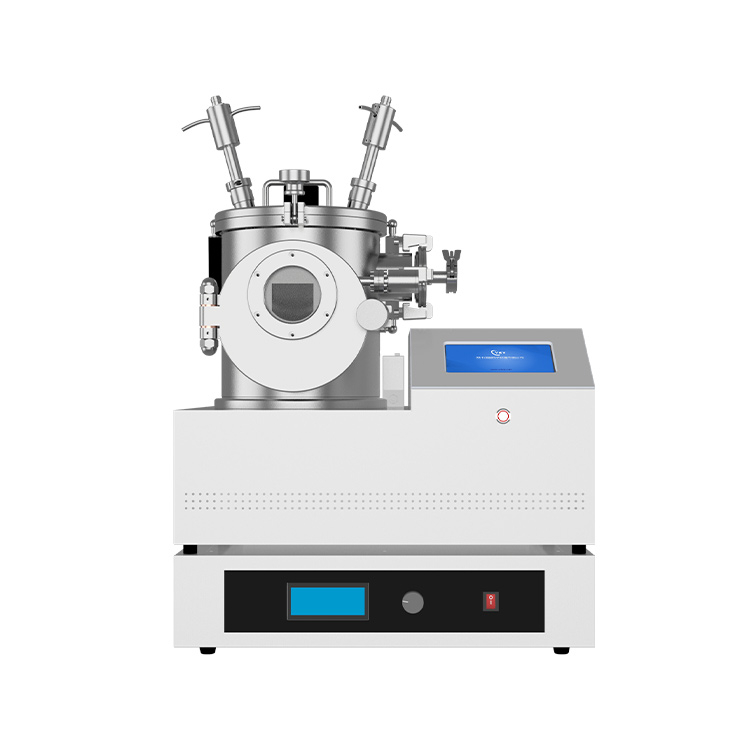

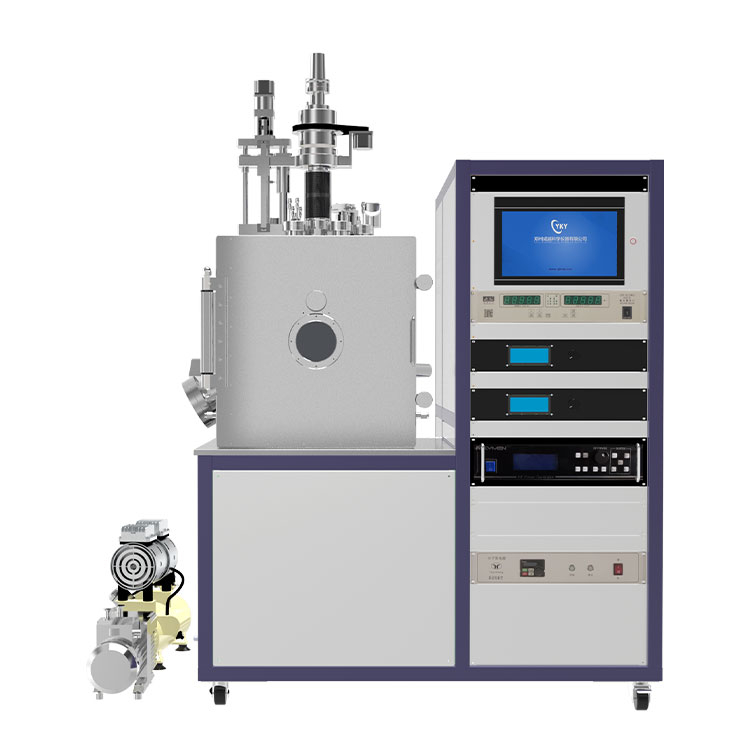

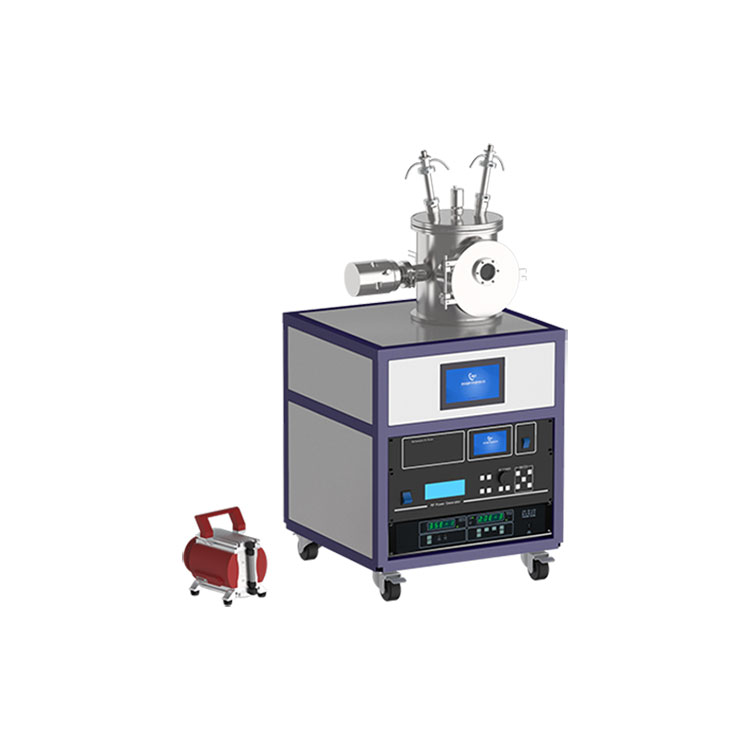

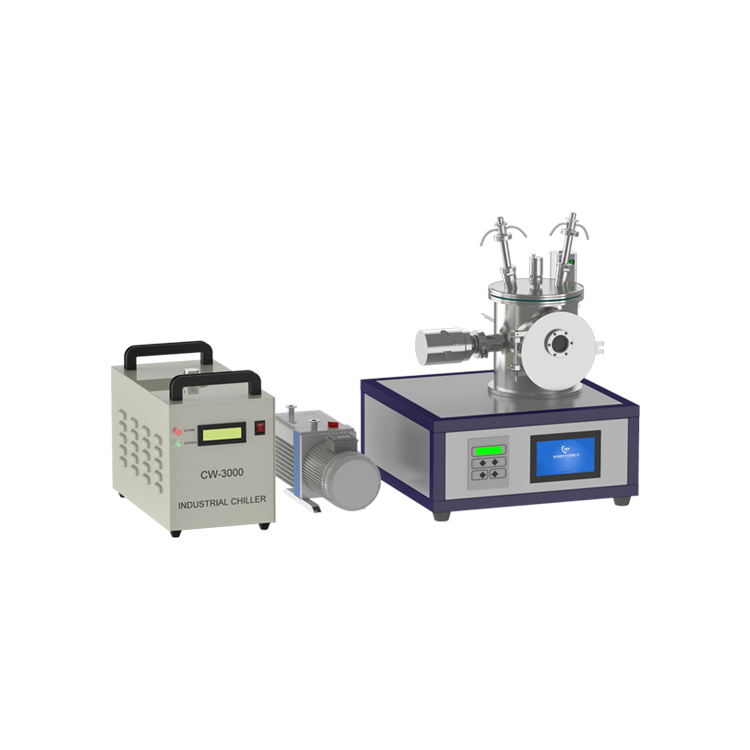

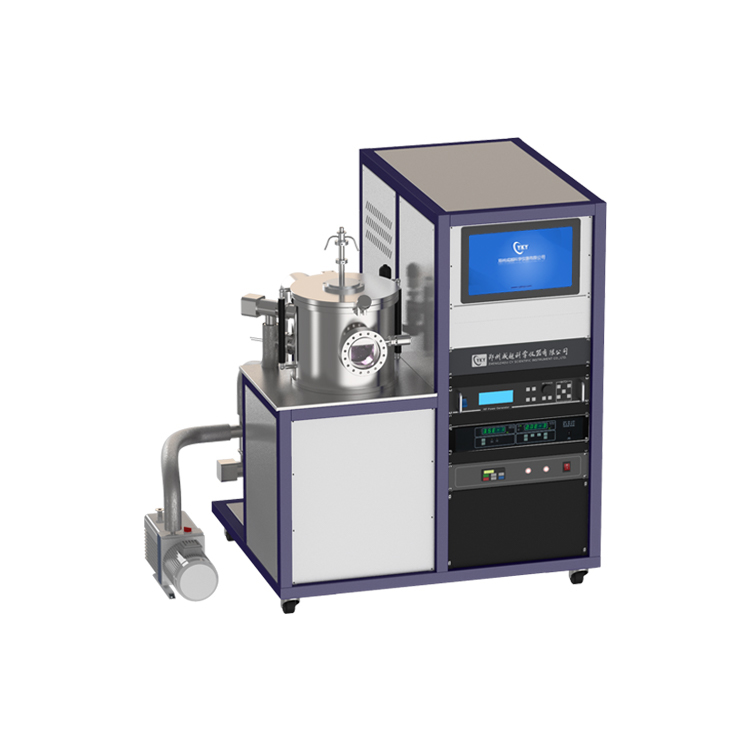

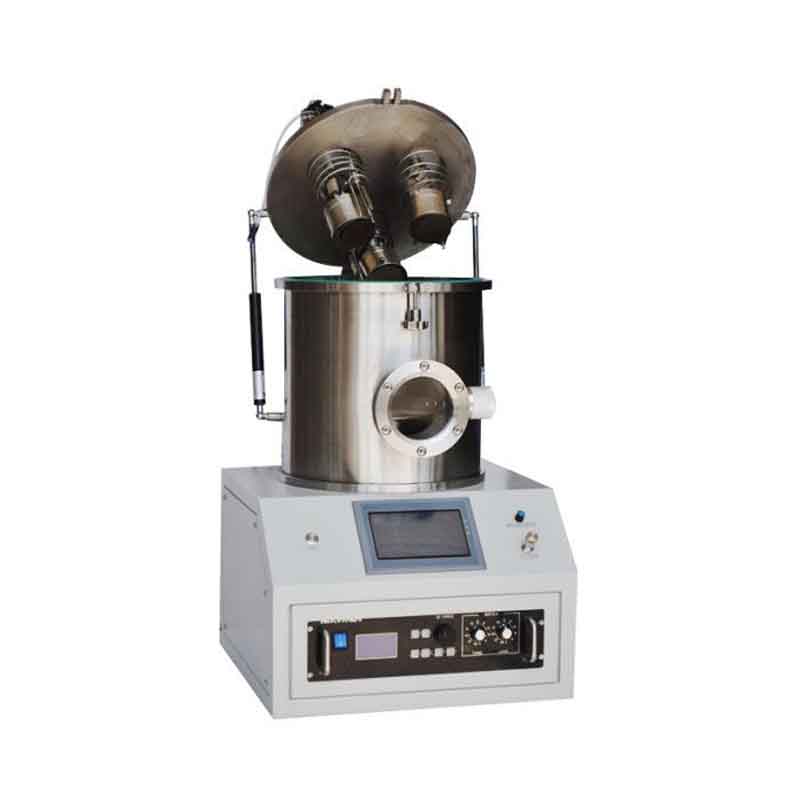

Main vacuum system | Sphere structure, size: dia. 450mm |

Loading sample system | Vertical cylindrical stucture, size: dia. 150×150mm |

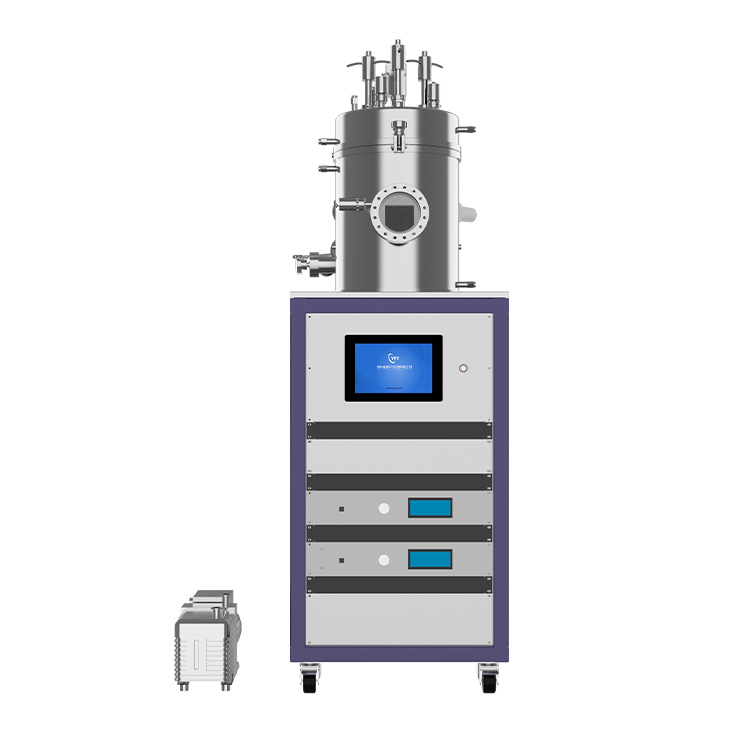

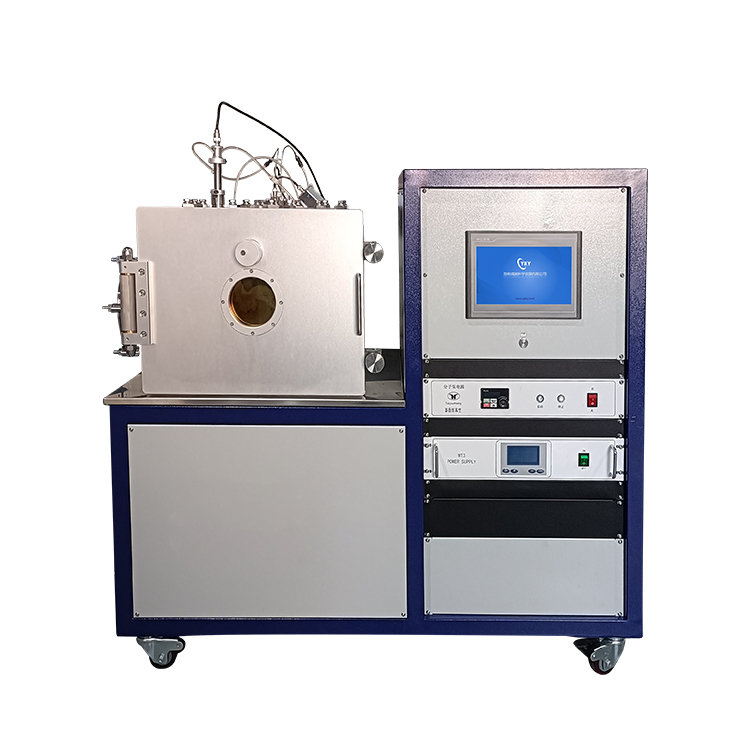

Vacuum system configuration | Main vacuum chamber | Mechanical pump, molecular pump, valve |

Loading sample system | Mechanical pump and molecular pump(sharing with primary chamber), valve |

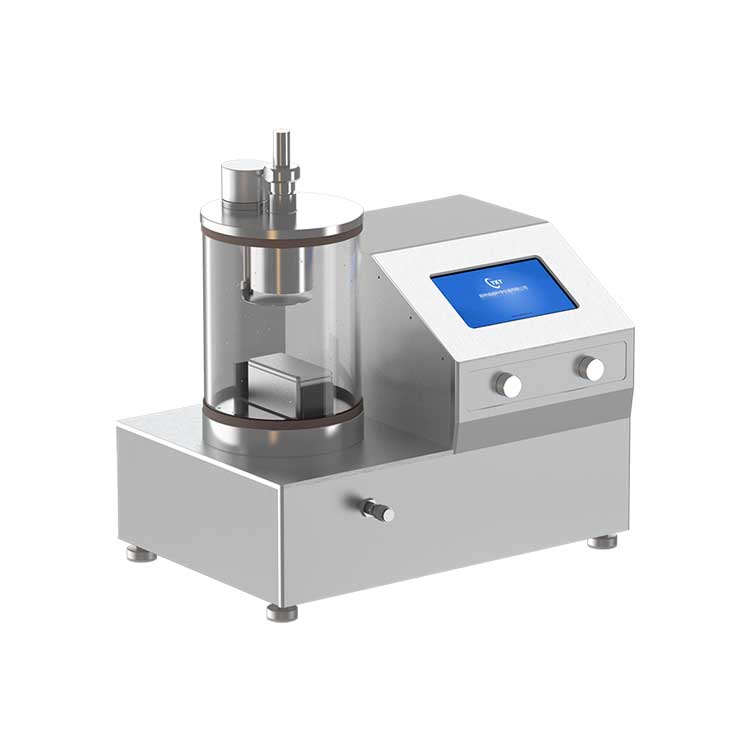

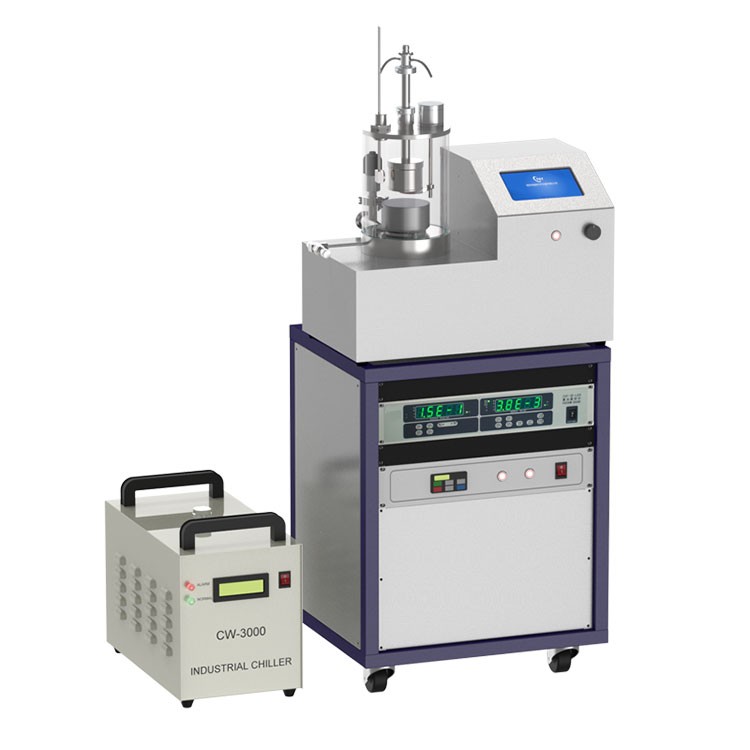

Ultimate pressure | Main vacuum system | ≤6*10-6Pa(after baking and degassing) |

Loading sample system | ≤6*10-3 Pa(after baking and degassing) |

Vacuum recovery system | Main vacuum system | It can reach 5x10-3Pa in 20 minutes (the system is exposed to the atmosphere for a short time and filled with dry nitrogen to start pumping) |

Loading sample system | It can reach 5x10-3Pa in 20 minutes (the system is exposed to the atmosphere for a short time and filled with dry nitrogen to start pumping) |

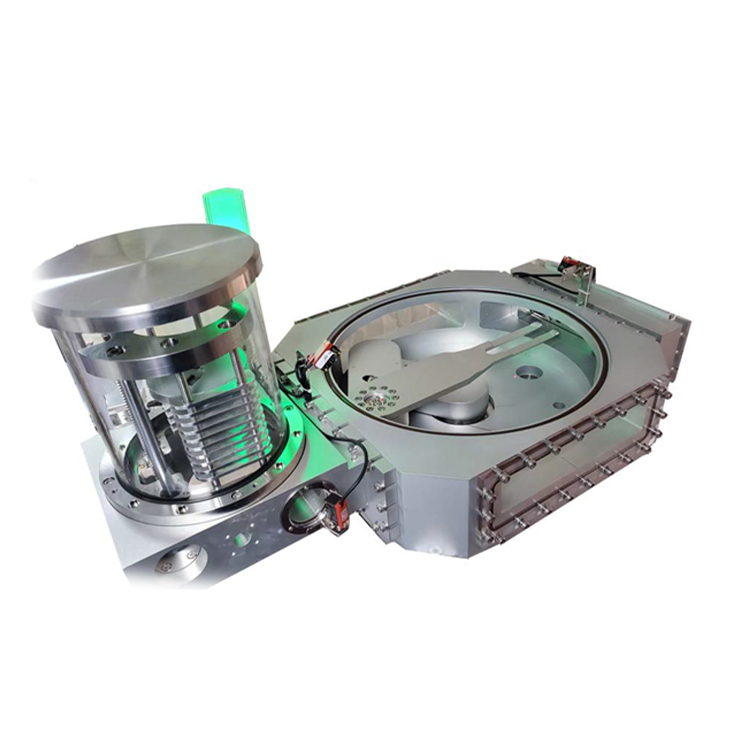

Rotating target platform | The maximum size of the target is about 60mm. Four target materials can be installed at one time, target changing in revolution motion; each target can rotate independently, rotation speed: 5-60 rpm |

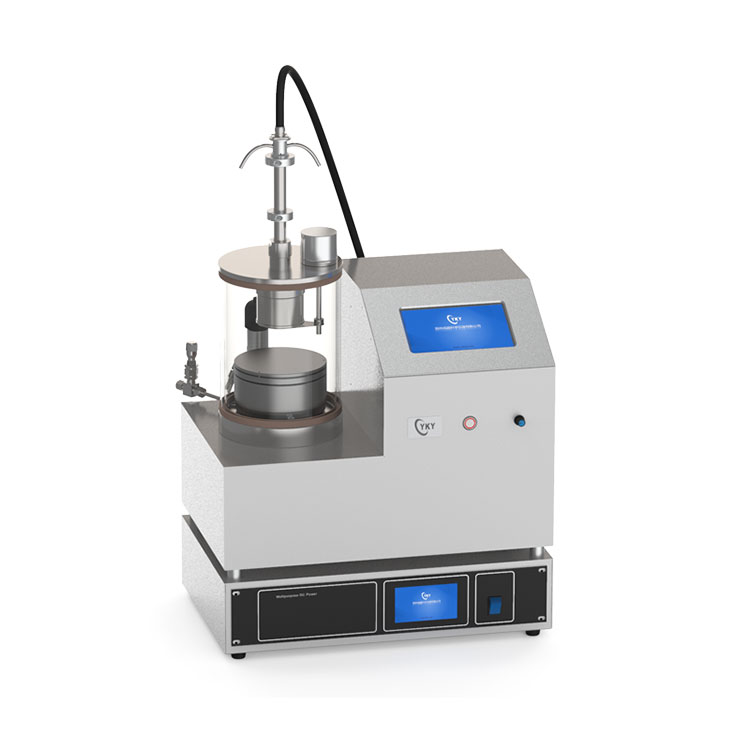

Substrate heating platform | Sample size | Dia. 51 |

Mode of motion | Substrate rotates continuously, rotation speed:5-60 rpm |

Heating temperature | Maximum temperature of substrate heating: 800℃±1℃, Controlled and adjustable |

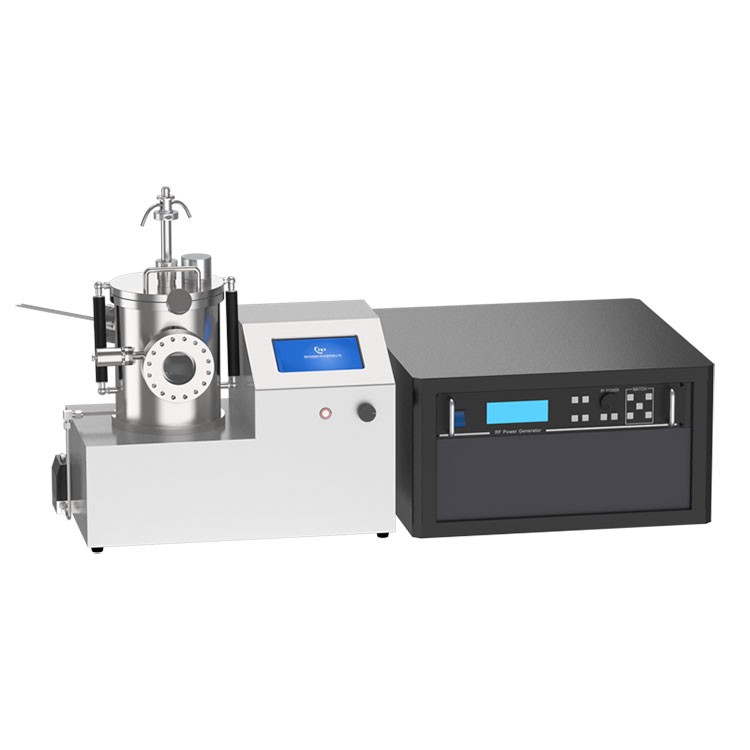

Gas circuit system | 1-circuit mass flow controller, 1-circuit inflation valve |

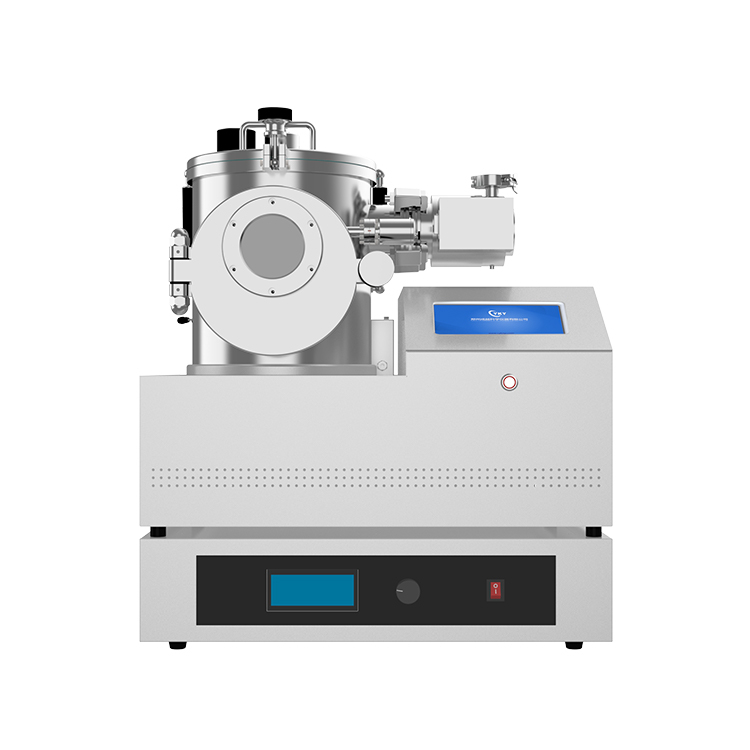

Optional accessories | Laser device | Compatible with coherent 201 laser |

Laser beam scanning device | 2D scanning mechanical platform, perform two degree of freedom scanning. |

Computer control system | The contents of control include common conversion target, target rotation, sample rotation, sample temperature control, laser beam scanning, etc. |

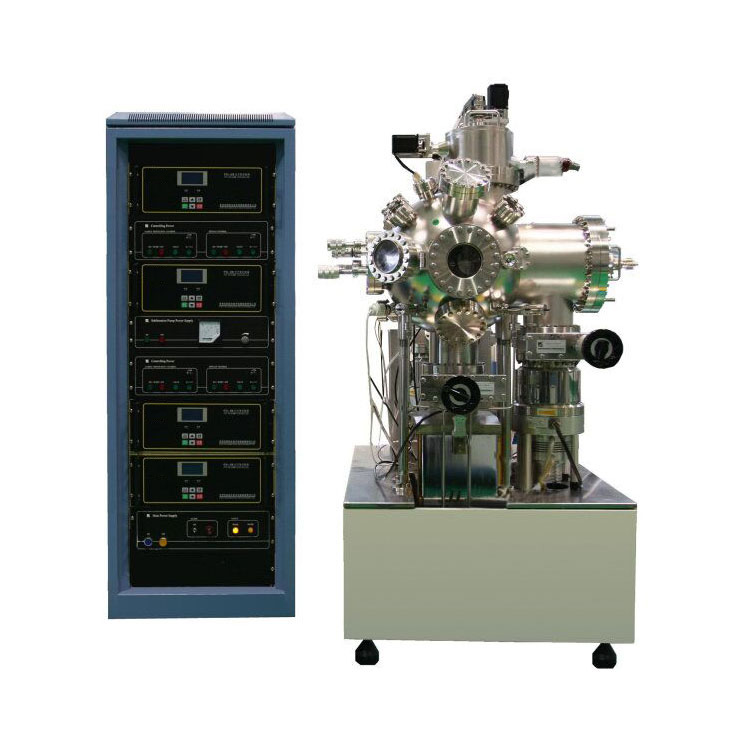

Floor Space | Main unit | 1800 * 1800mm2 |

Electric cabinet | 700 *700mm2(one) |