Basic Info

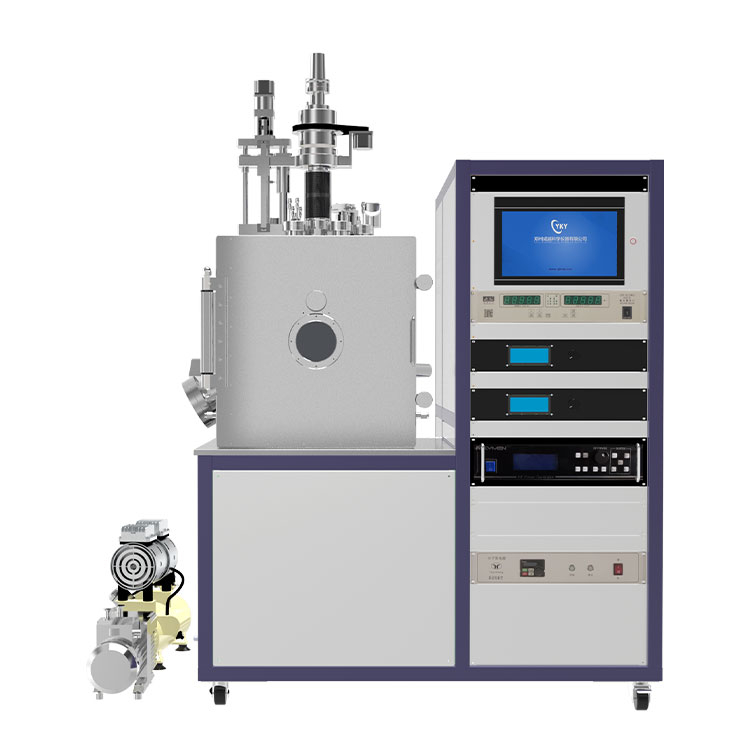

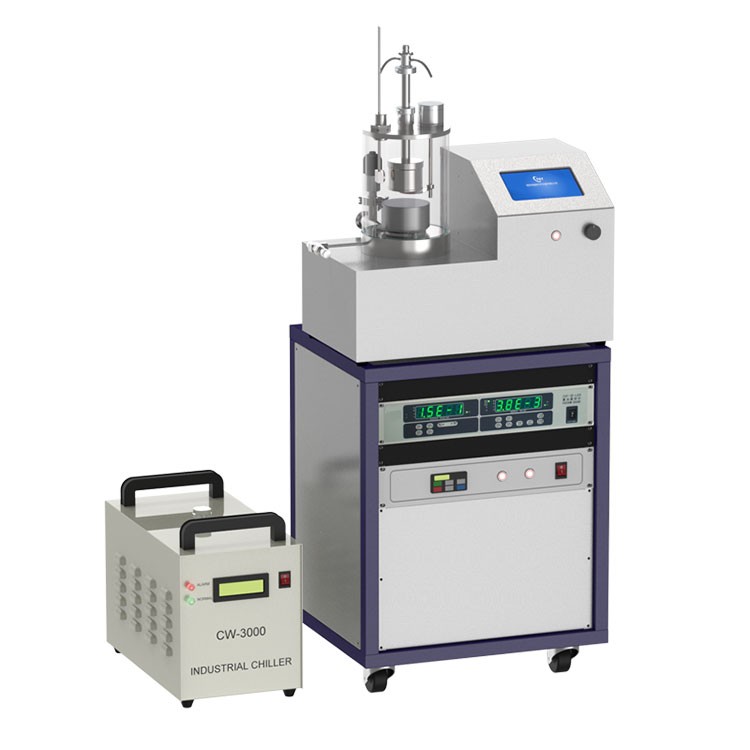

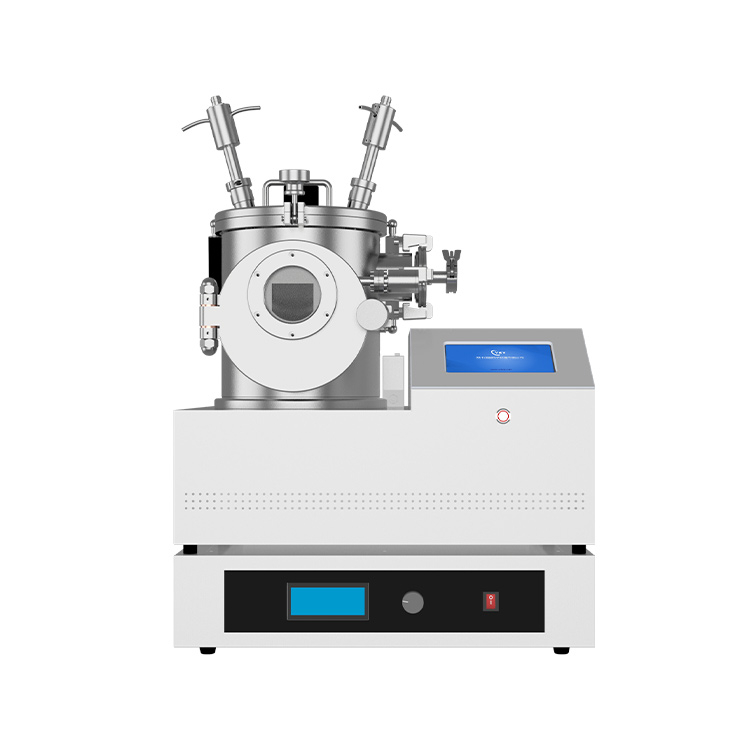

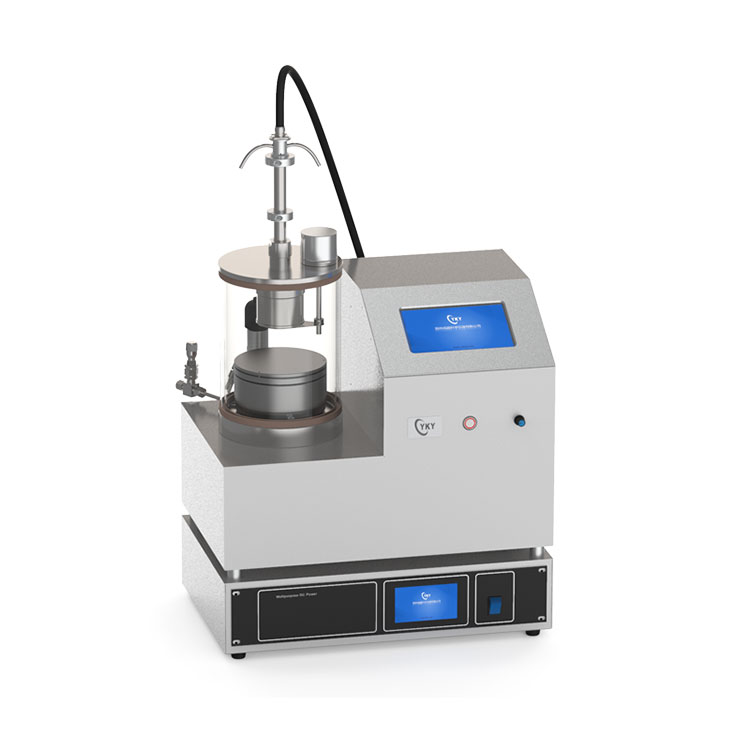

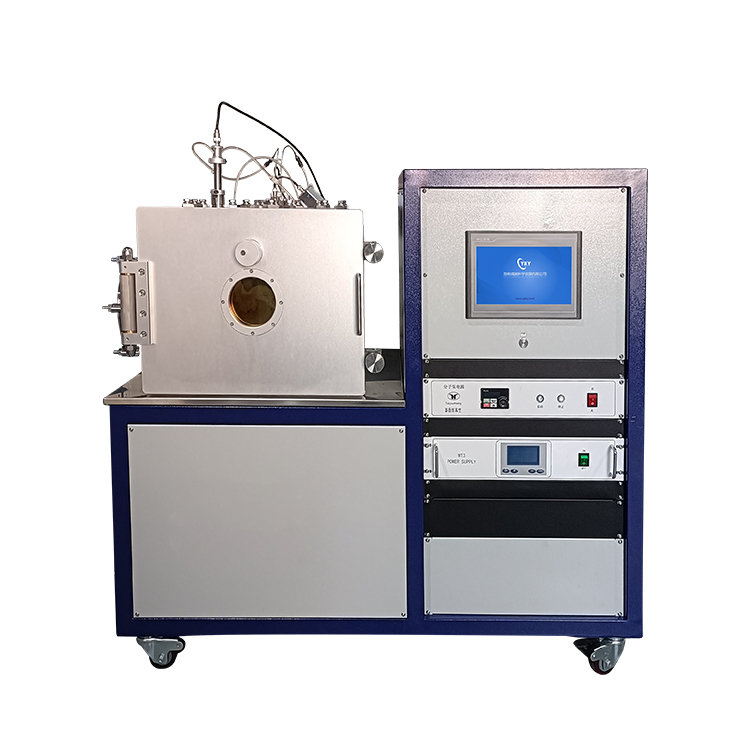

Model NO.: CY-VTC-600-2HD

Structure: Desktop

Certification: CE, TUV

Type: Measurement Type

RF Source: 600W

Gas Flow Control: Mass Flow Meter

Trademark: CY

Specification: 300 mm Dia x 300 mm height

HS Code: 85141090

Customized: Customized

Material: Stainless Steel

Application: Lab

DC Source: 500W

Vacuum Chamber: Stainless Steel

Warranty: One Year

Transport Package: Wooden Box

Origin: Zhengzhou, China

Product Description

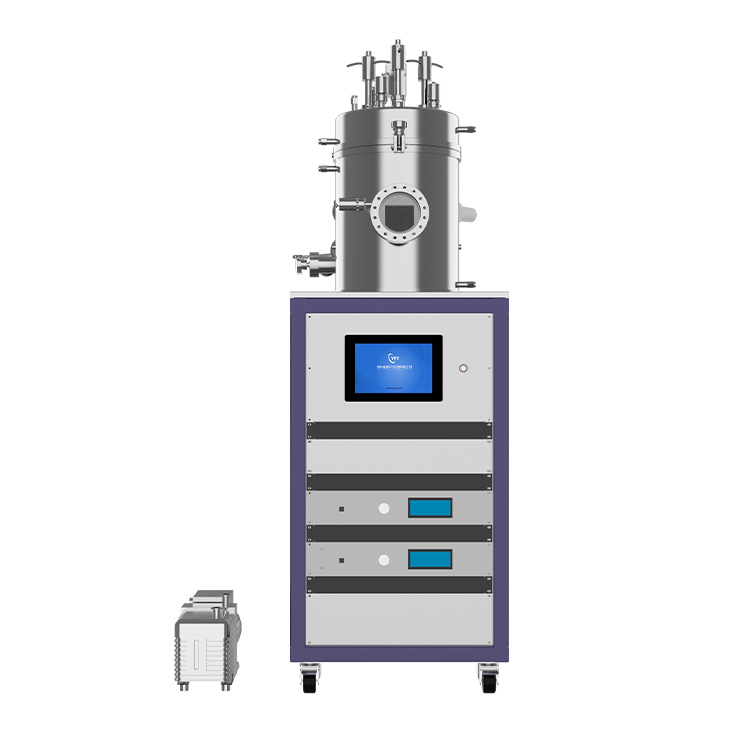

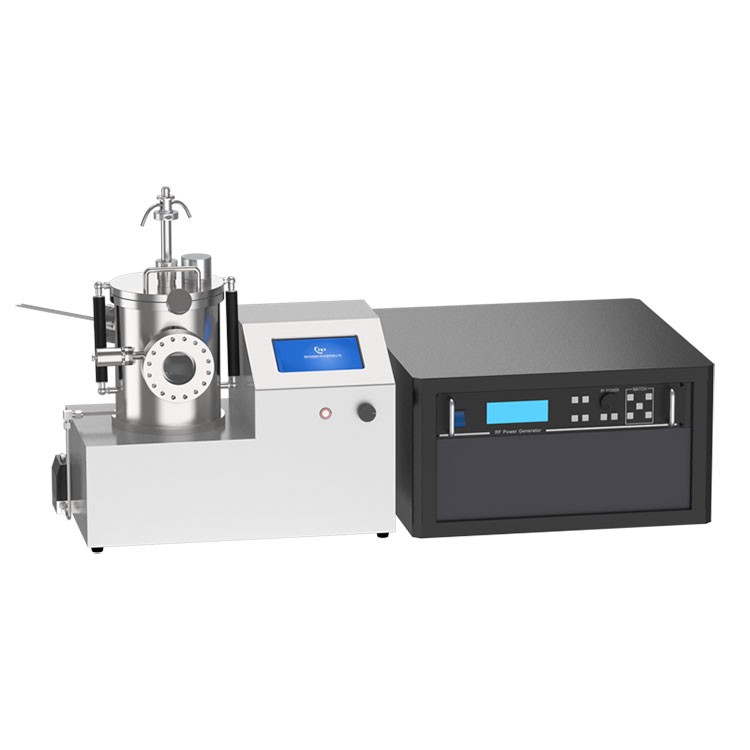

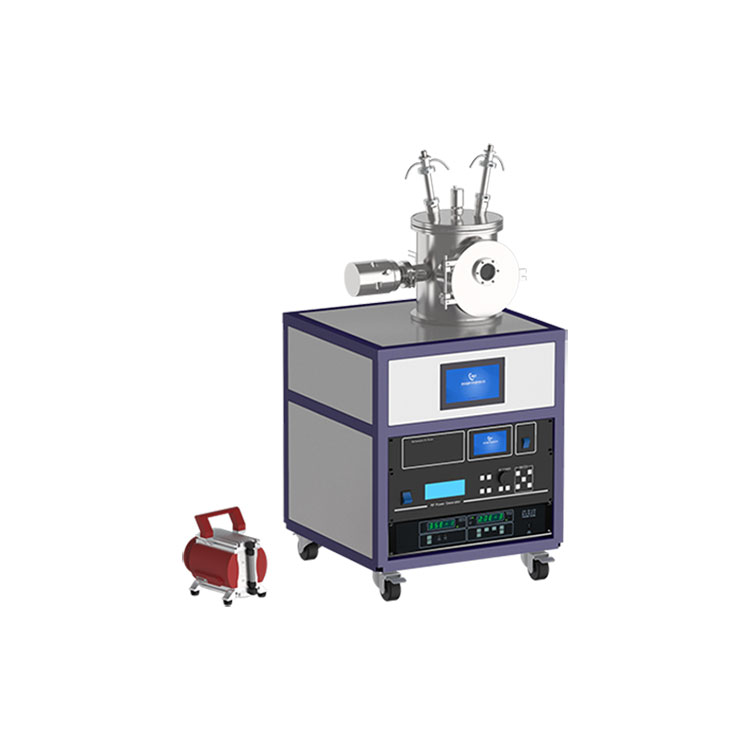

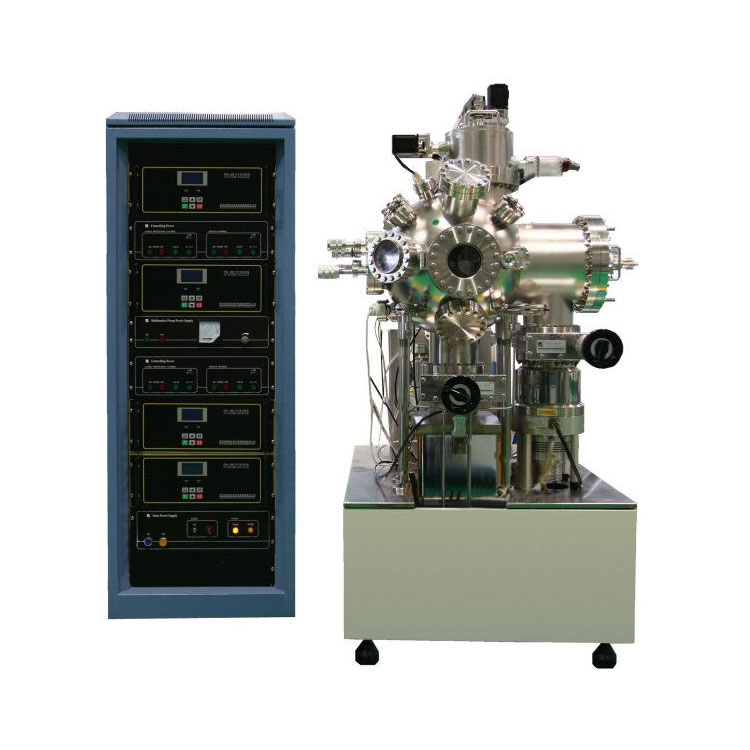

Dual-Head Magnetron Plasma Sputtering system / Magnetron Sputter Coater

CY-VTC-600-2HD is a compact magnetron sputtering system with dual 2" target sources, e.g., one DC source for coating metallic film, and another RF source for coating non-metallic material. A film thickness tracker is included to enable the user to control processing easily. This coater is designed for coating both single or multiple film layers for a wide range of materials, such as alloy, ferroelectric, semiconductor, ceramic, dielectric, optical, PTFE etc. at low cost.

Specification

| Input Power | 220VAC 50/60Hz, single phase

2000W (including pump) |

| Source Power | Two sputtering power sources are integrated into one control box

DC source: 500W for coating metallic materials

RF source: 600W with automatching for coating non-metallic materials ( Center)

Compact 300 RF source is available at extra cost |

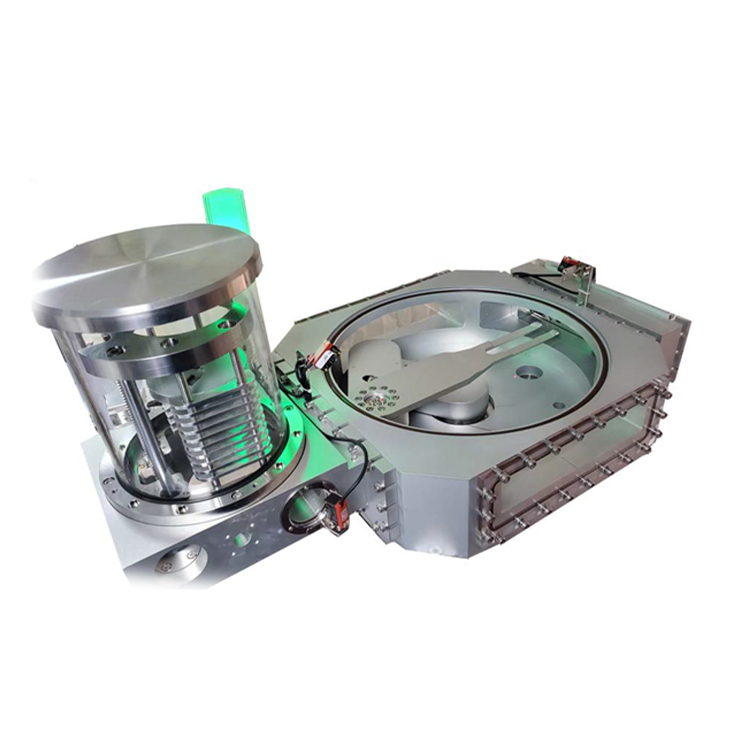

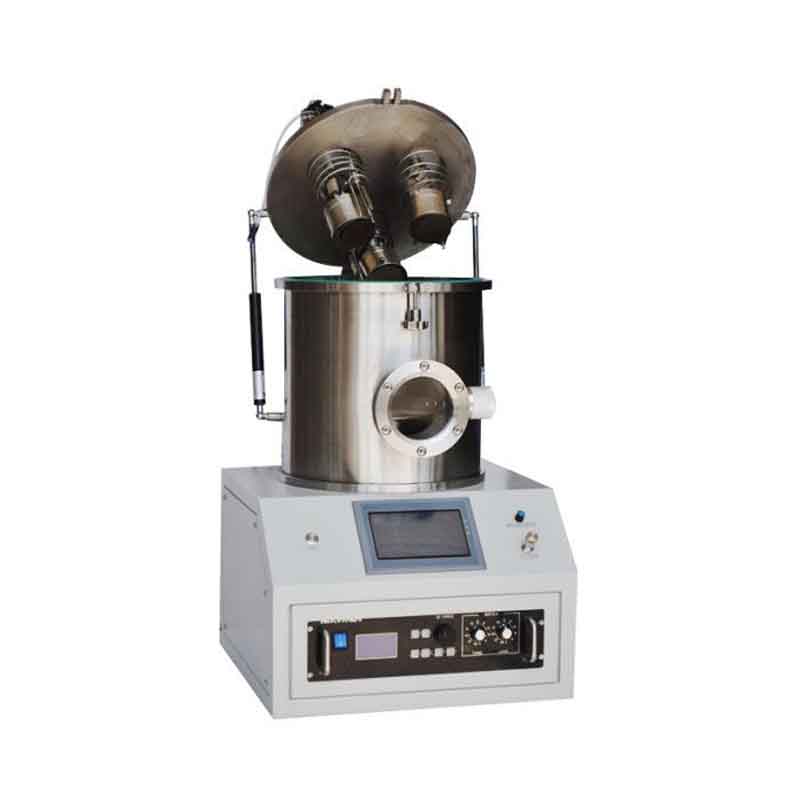

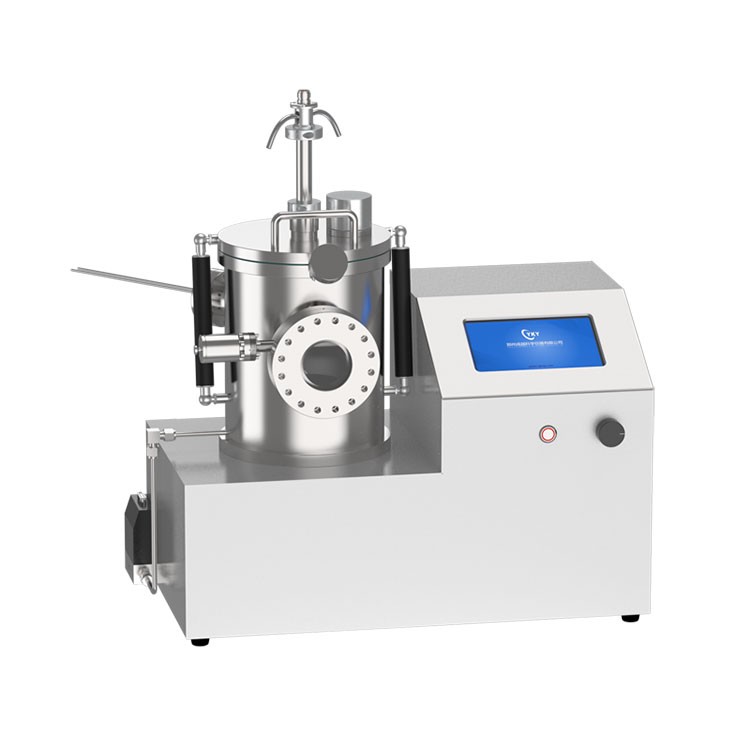

| Magnetron Sputtering Head | Two 2" Magnetron Sputtering Heads with water cooling jackets are included

One is connected to RF power supply for no-conductive materials

Another is connected to DC sputtering power source for coating metallic materials

Target size requirement: 2" diameter

Thickness Range: 0.1 - 5 mm for both metallic and non-conductive targets

One stainless steel and one Al2O3 ceramic targets are included for demo testing

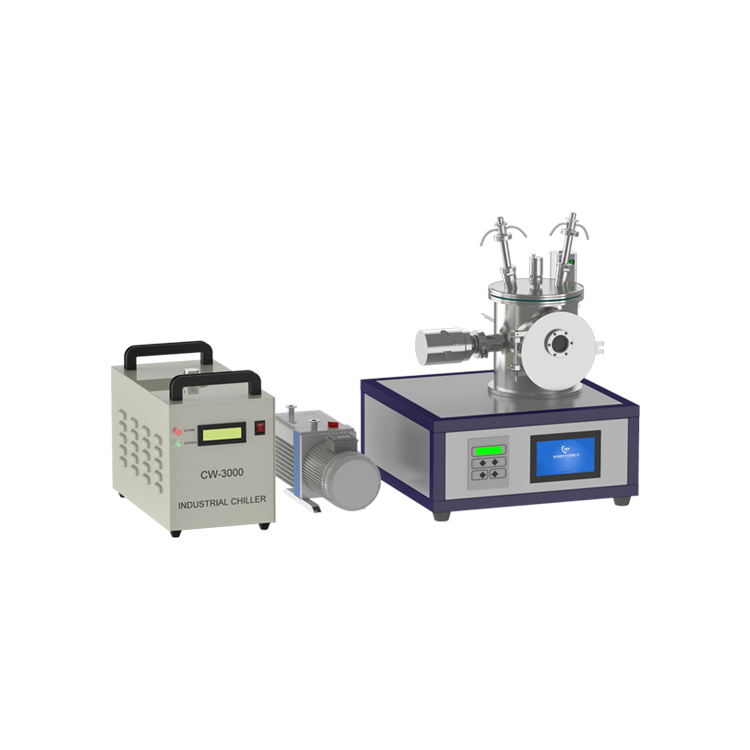

Head Water Cooling: 10ml/min water flow required, and one 16ml/min digitally controlled recirculating water chiller is included for cooling both magnetron sputtering heads

Customized coater: Two DC head without, RF sputtering, RF head without DC sputtering, 3 RF head are available upon request |

Vacuum

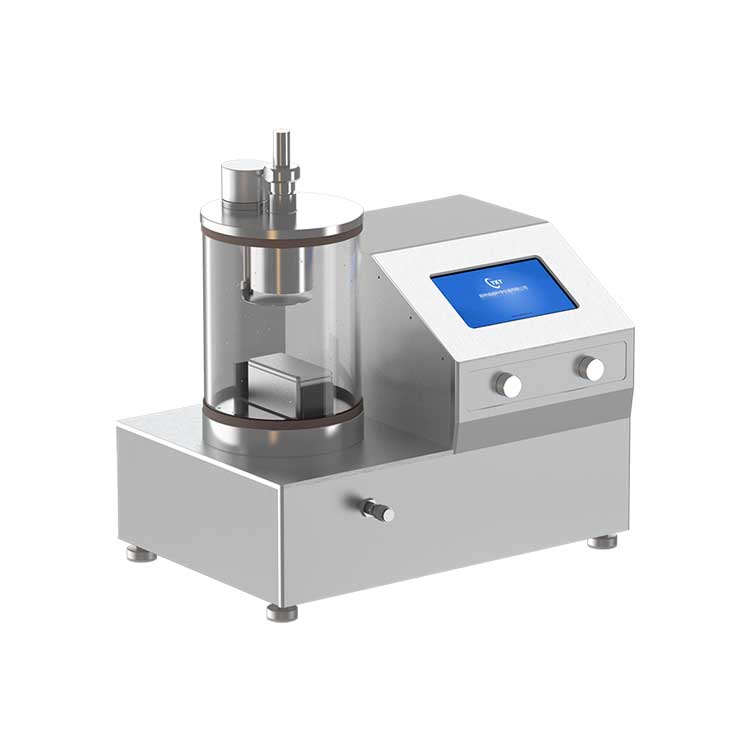

Chamber | Vacuum Chamber: 300 mm Dia x 300 mm height, made of stainless steel

Observation Window: 100 mm diameter

Hinged type cover on top with air spring sport makes target exchange easy |

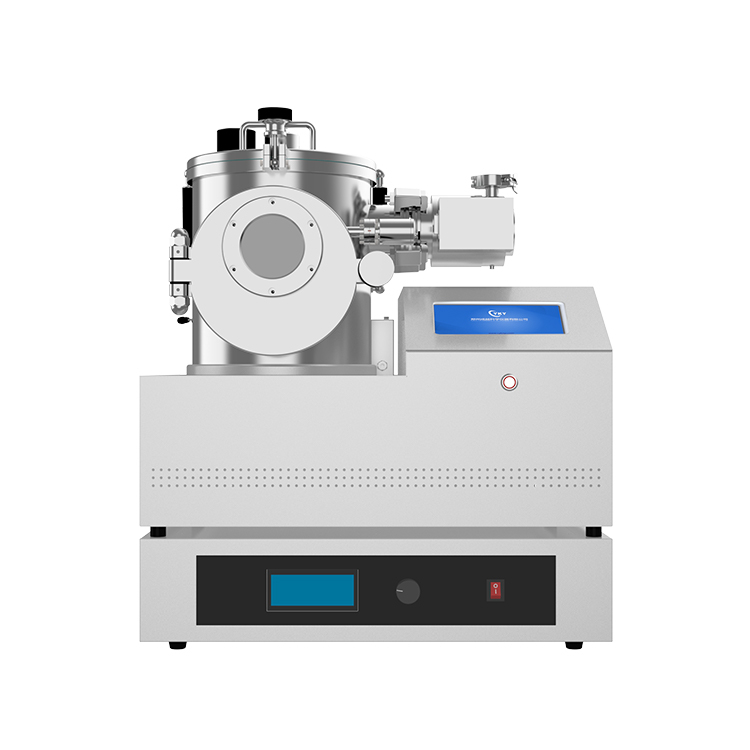

| Sample Holder | Sample holder size: 140mm dia. for. 4" wafer max

(also can be designed as your requirement)

Sample holder rotation speed is adjustable: 1 - 20 rpm for uniform coating

The holder temperature is adjustable from RT to 500°C Max with accuracy +/- 1.0 °C |

Gas Flow

Control | Two precision digital MFC (mass flow controller) are installed to allow two types of gases to be filled in

Flow rate: 200 ml/min max.

Flow rate is adjustable on the 6" touch screen control panel |

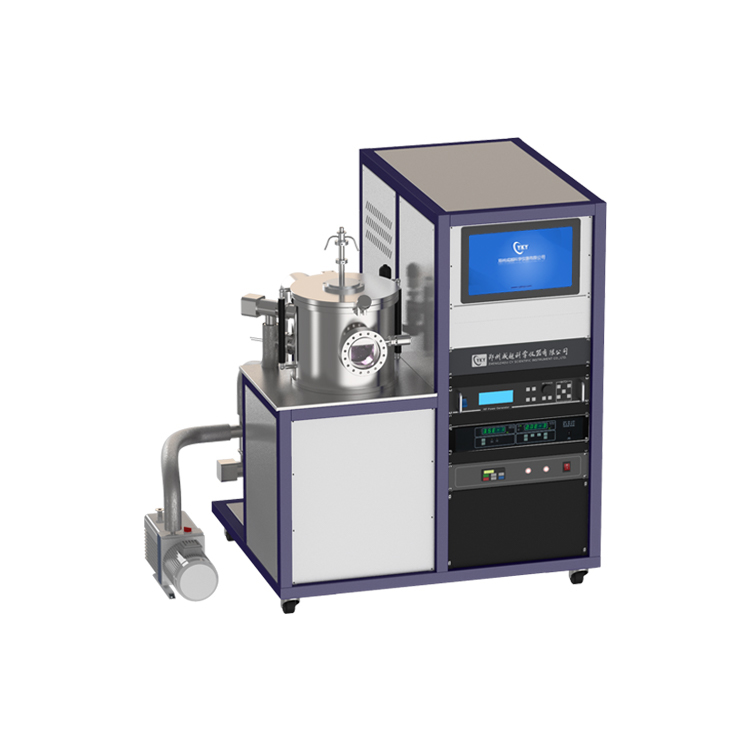

Vacuum Pump

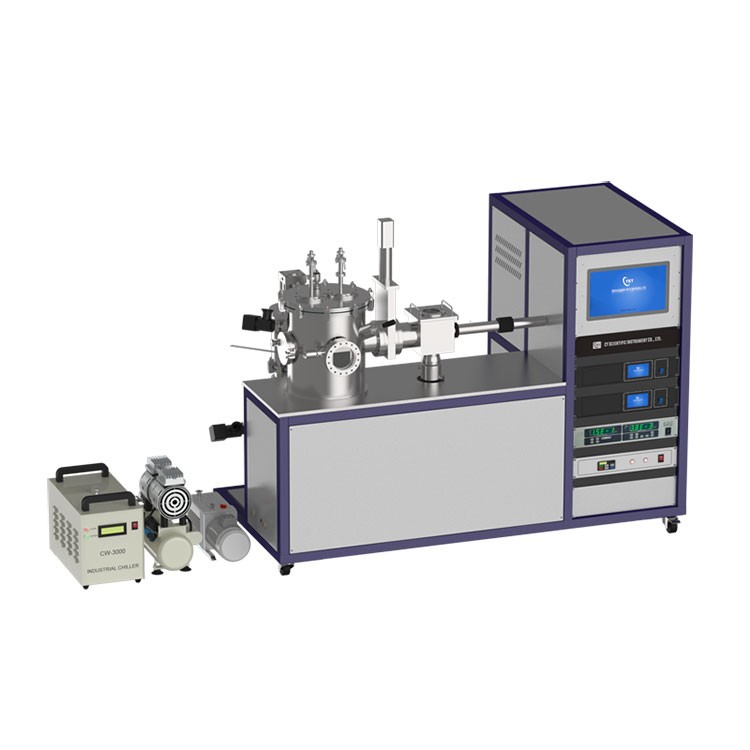

Station | High speed turbo vacuum pump system (made in Germany) is directly installed on the vacuum chamber for max. vacuum level

Heavy duty dual stage mechanical pump is connected to turbo pump for faster pump speed

Mobile pump station is included and the compact sputtering coater can be put on top of station

Max. vacuum level: 10^-6 torr with chamber baking |

Thickness

Monitor | One Precision quartz thickness sensor is built into the chamber to monitor coating thickness with accuracy 0.10 Å

LED Display Unit outside chamber can:5 pcs quartz sensors (consumable) are included

Input material to be coated according to data base included

Display total thickness coated and coating speed

Water cooling is required |

Overall

Dimensions | L1300mm× W660mm× H1200mm |

| Net Weight | 160 kg |

| Warranty | One years limited warranty with lifetime support |

| Application Note | In order to remove oxygen from the chamber, suggest you use 5% Hytrogen + 95 % Nitrogen to clan chamber 2-3 times, which can reduce oxygen to below 10 ppm

Please use > 5N purity Argon gas for plasma sputtering. Even though 5N purity Ar, usually contain 10- 100 ppm oxygen and H2O |

Package

Service

1. Factory prices with the best quality.

2. One year free-of-charge maintenance for all the dental equipment

3. Customized service for special demand

4. Fast and flexible delivery, by sea, by air, by express

5. Quick response within 24 hours

How to order

1. If you are interested in our products, please tell us the model number and quantity.

2. We will make a proforma invoice for your order.

3. We will deliver the product ASAP on receipt of the payment

Guarantee

1. Guarantee for one year after shipment.

Payment

1. Western Union

2. PayPal

3. Secure Payment through Alibaba

4. Telegraphic transfer

5. L/C

Factory

Zhengzhou CY Scientific Instrument Co., Ltd is mainly engaged in the research and development, design, manufacturing and sales of equipment used in scientific researches. Independence and innovation is the company's tenet.Our main products include: tube furnace, muffle furnace, plasma cleaner, vacuum furnace, atmosphere furnace,CVD system and customized lab equipment.Welcome you come to visit us.

Exhibition