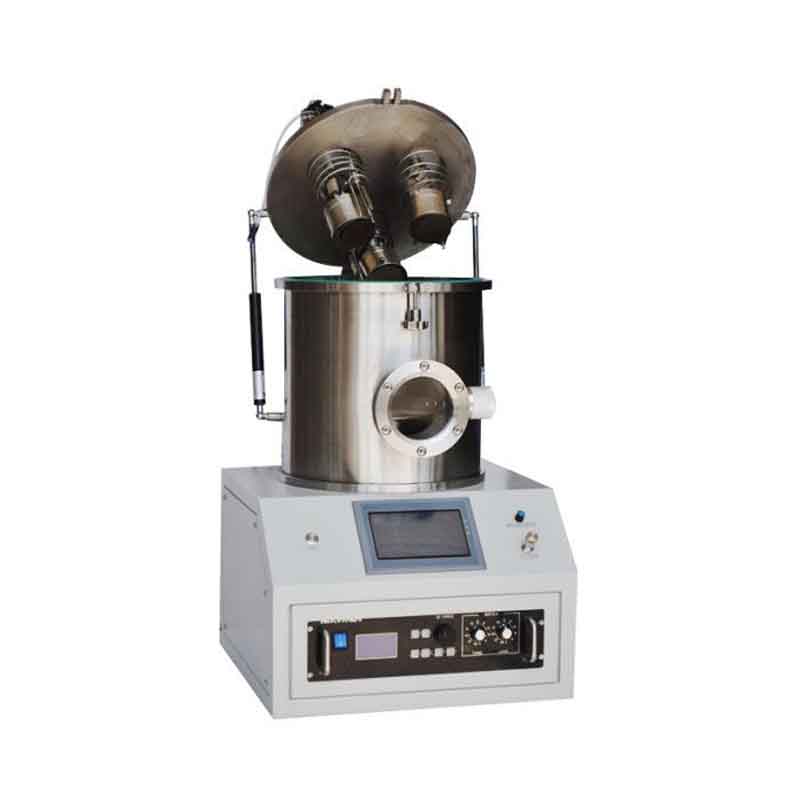

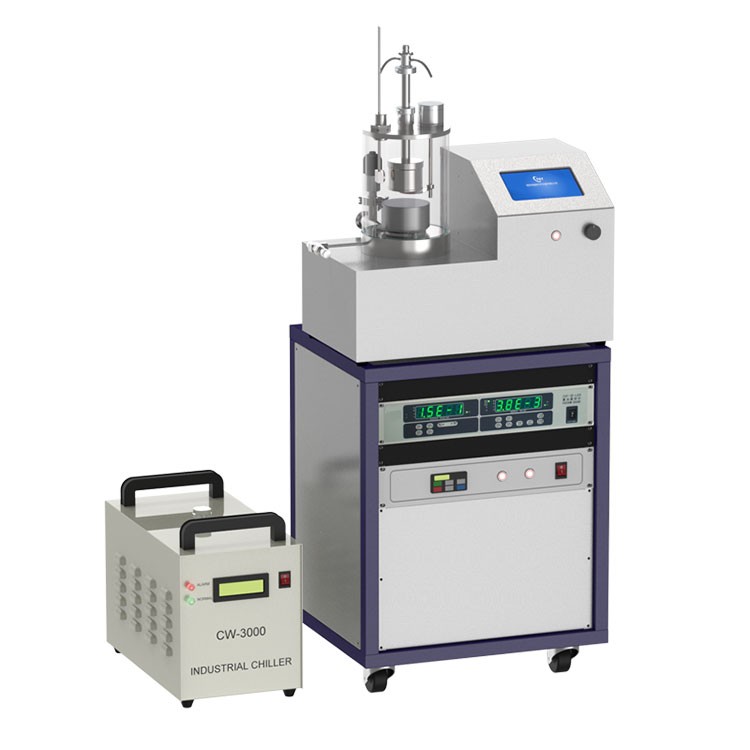

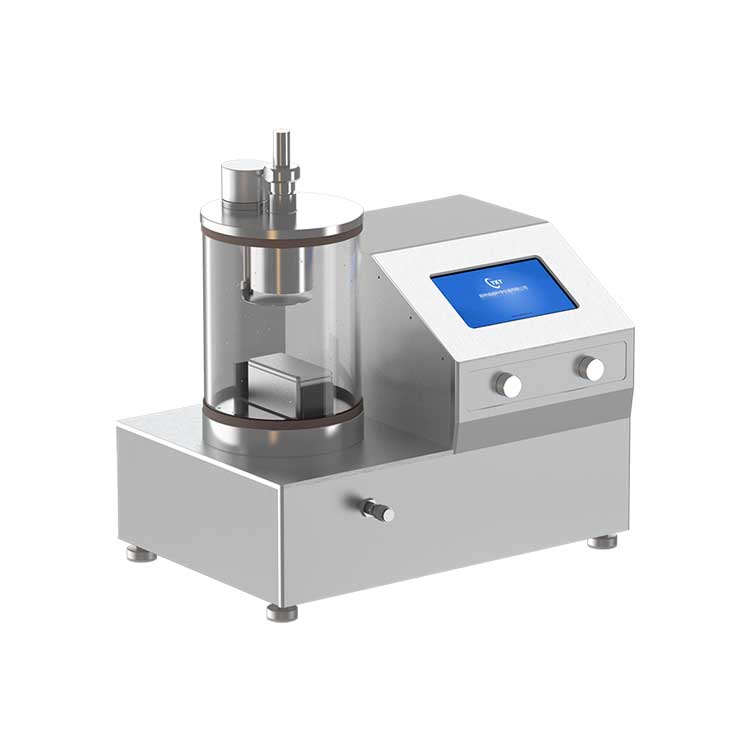

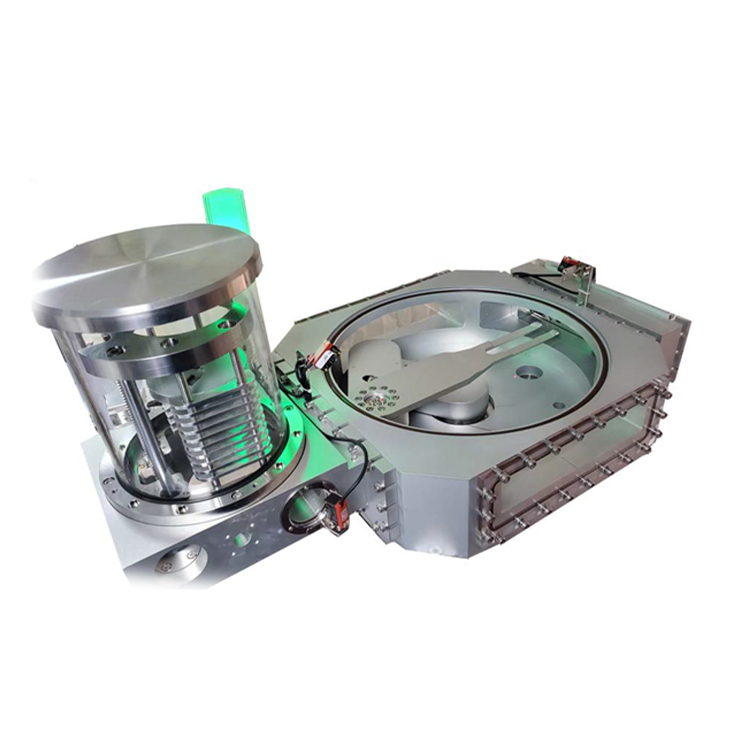

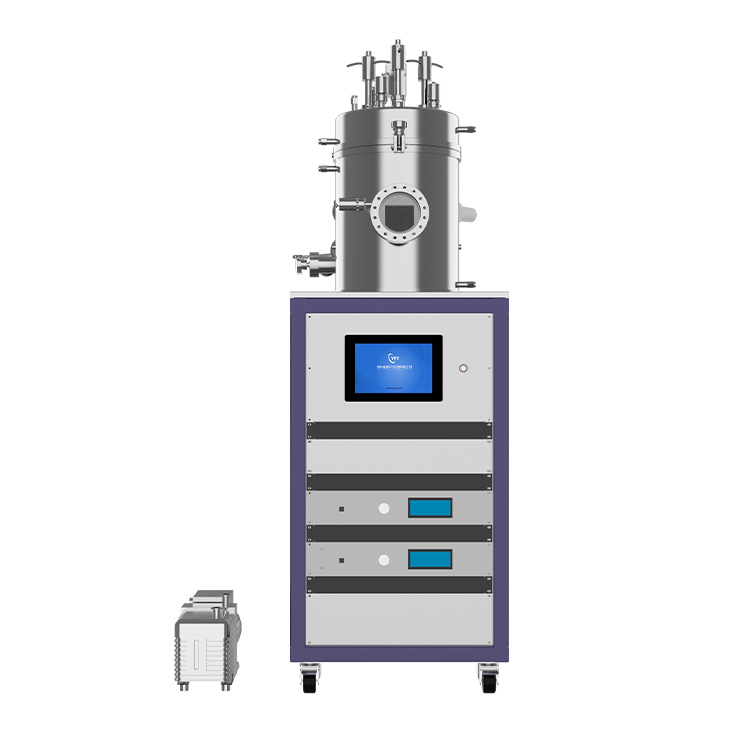

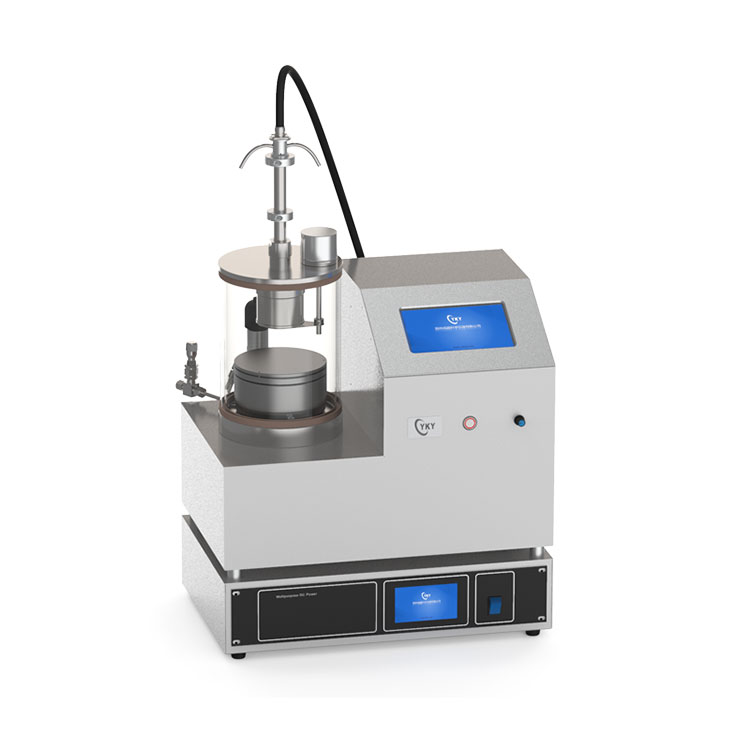

1. Input voltage: 220 VAC 50/60Hz 2. Power output: 1600 VDC 250 W 3. Maximum current: 150 mA. 4. Sputtering head: 2 inch angle adjustable sputtering head 5. Vibration sample stage: Sample table vibration frequency can be adjusted: 6-33Hz Sample stage diameter: 50mm Recommended sample amount: < 500 mg Recommended particle size: 1 ~ 1000um Quartz chamber size: 165 mm OD.×150 mm ID×250 mm H 6. Vacuum degree: (1) 1.0E-2 Torr (with mechanical pump), can sputter Au, Ag, Pt, Cu, Mo and other targets (2) 1.0E-5 Torr (with molecular pump), can sputter Al, Mg, Li, Lr, Ti, Zn and other easily oxidized metal targets, the maximum vacuum can reach < 4.0E-6 Torr (molecular pump system vacuum pumping time 12 hours , the chamber is baked) 7. CE certification |