Basic Info

Model NO.: CY-VTC-600-2HD

Coating: Plasma Sputtering Coater

Certification: CE

Product Name: DC/RF Dual-Head Magnetron Plasma Sp

RF Source: 300W

Transport Package: Wooden Case

Origin: China

Type: Coating Production Line

Substrate: Ceramic and Metal

Condition: New

DC Source: 500W

Trademark: CYKY

Specification: plasma sputtering system

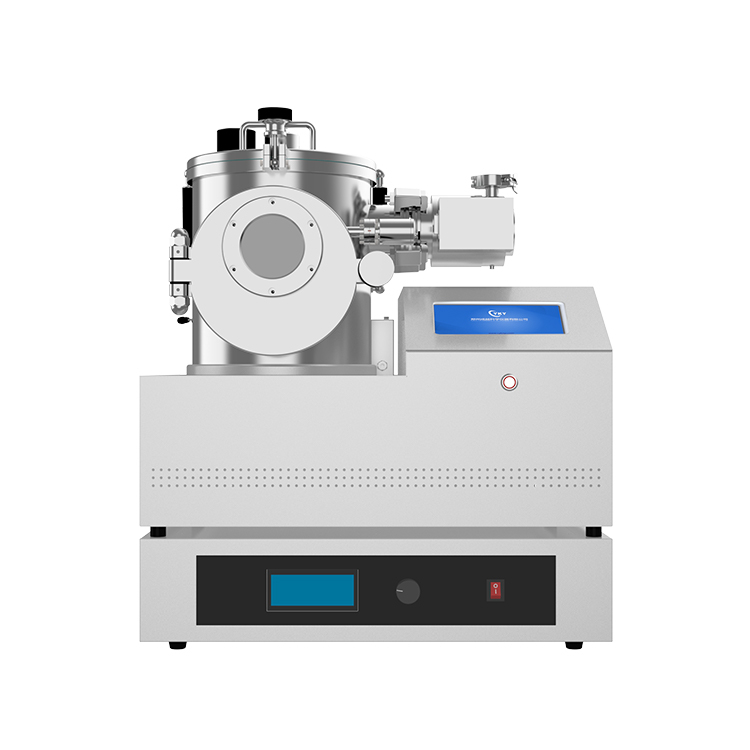

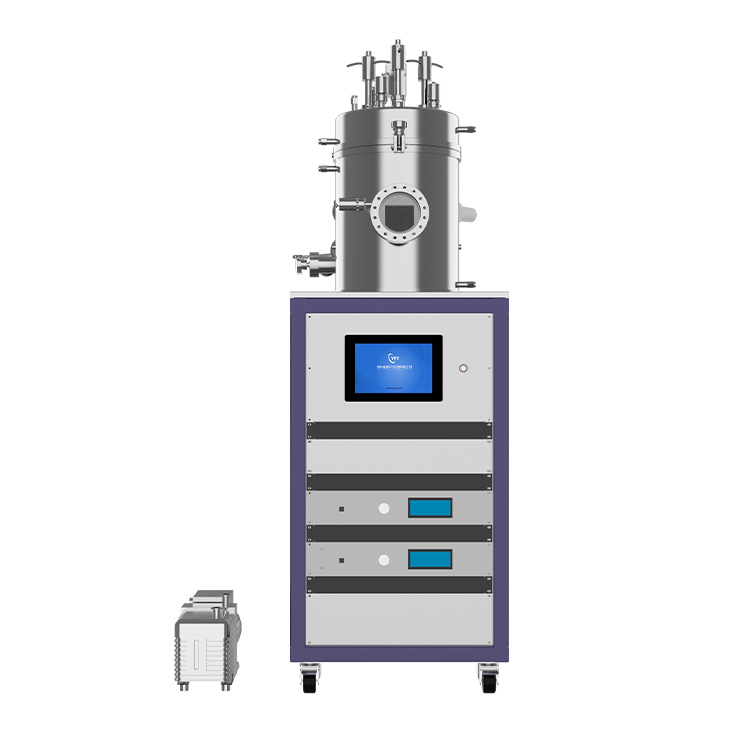

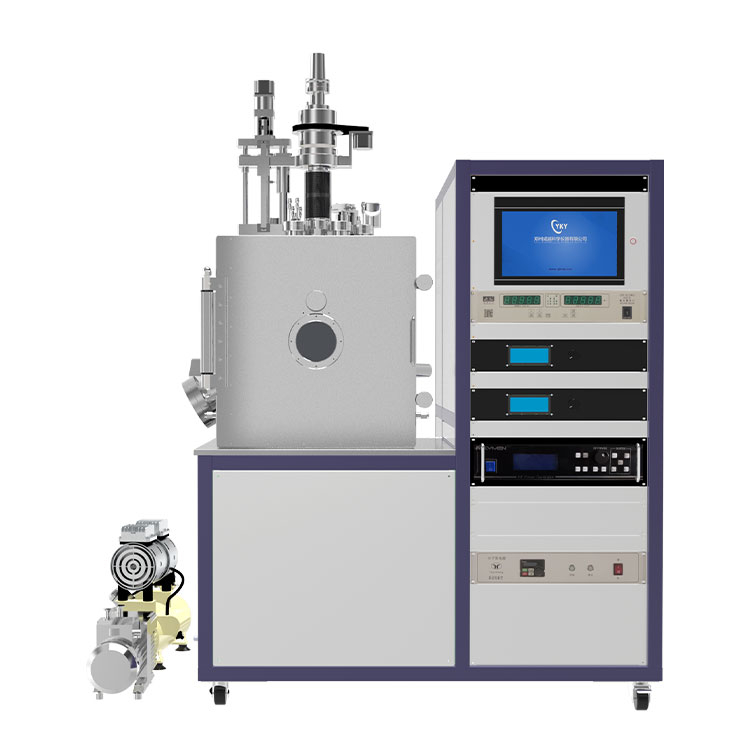

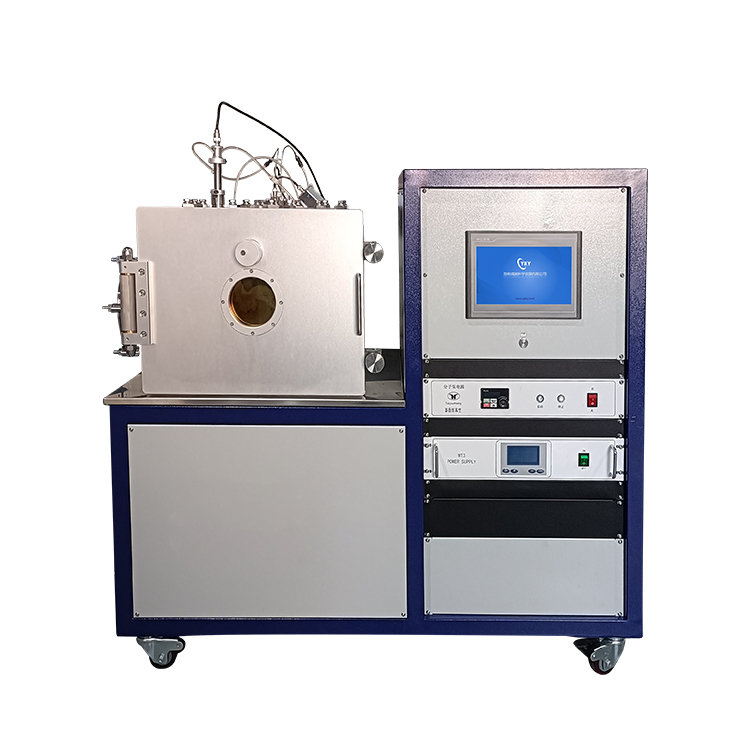

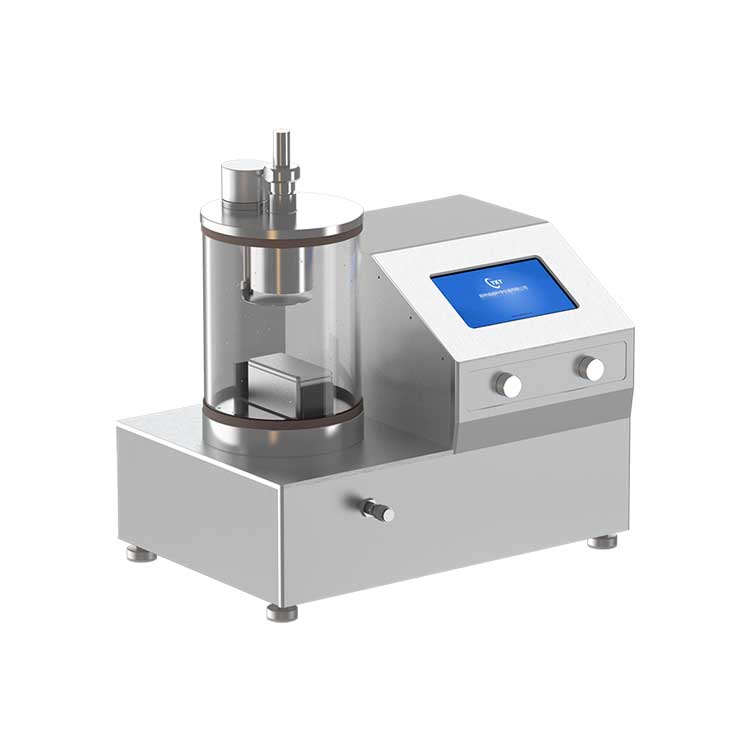

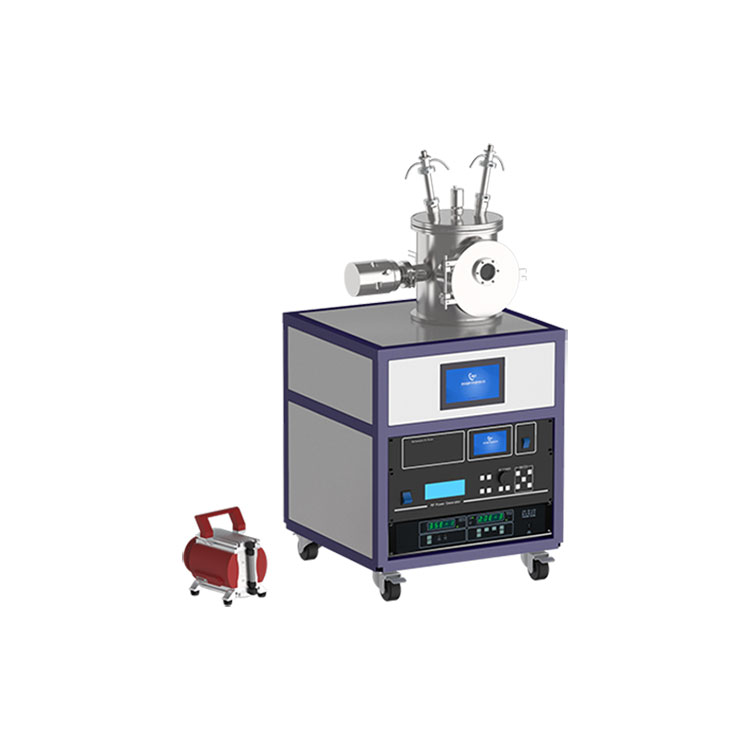

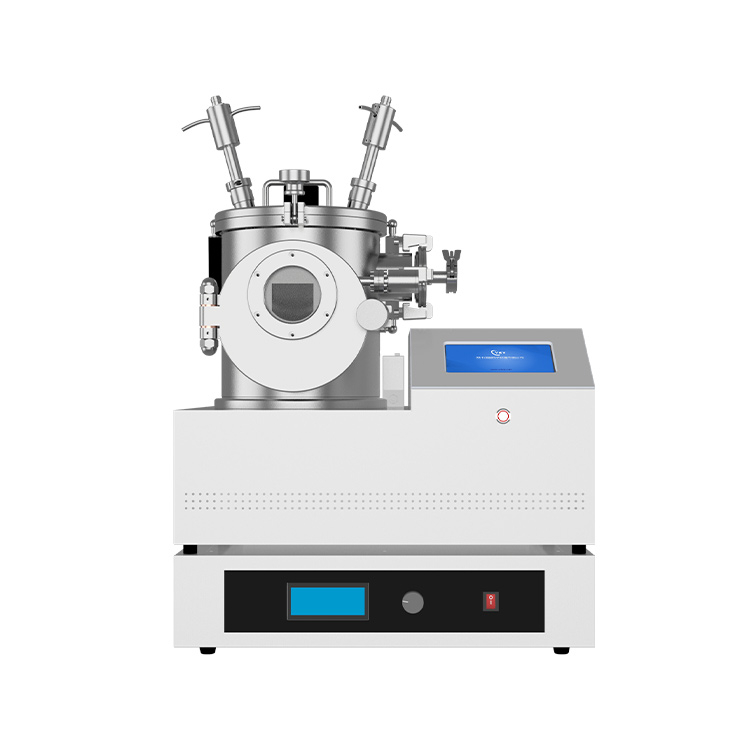

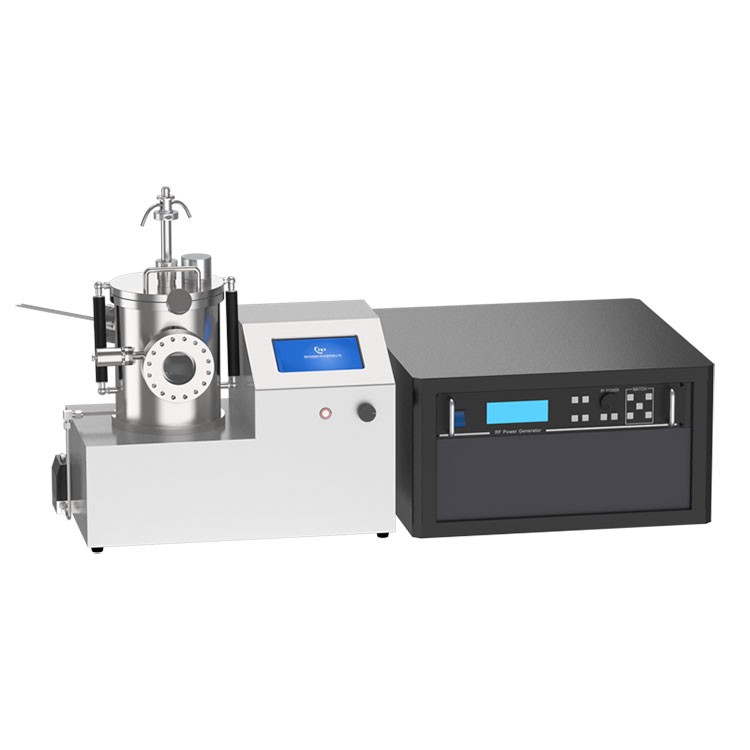

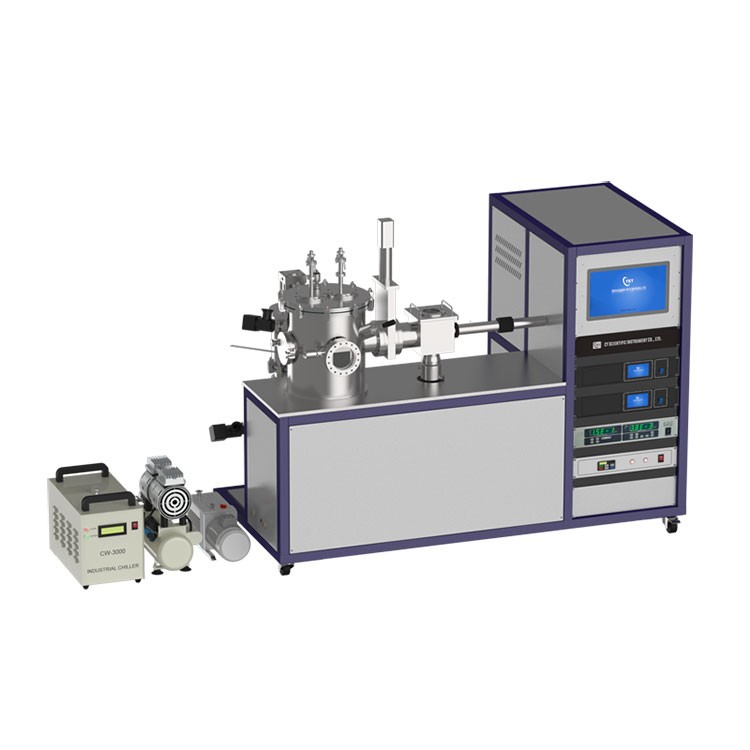

Product DescriptionDC/RF Dual-Head High Vacuum 2" Magnetron Plasma Sputtering Coater

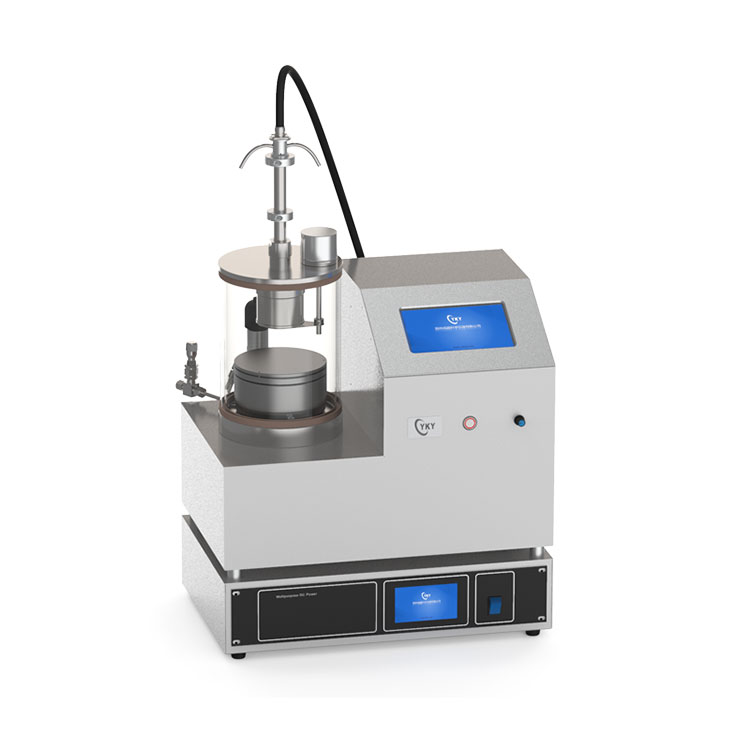

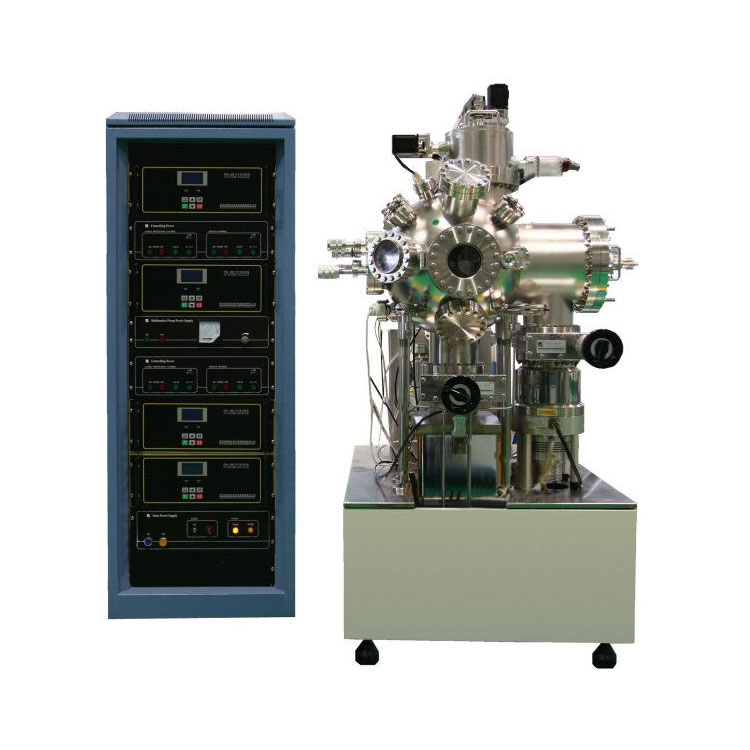

CY-VTC-600-2HD is a compact magnetron sputtering system with dual 2" target sources, e.g., one DC source for coating metallic film, and another RF source for coating non-metallic material. A film thickness tracker is included to enable the user to control processing easily. This coater is designed for coating both single or multiple film layers for a wide range of materials, such as alloy, ferroelectric, semiconductor, ceramic, dielectric, optical, PTFE etc. at low cost.

Specification of the dual head magnetron plasma sputtering coater

| Input Power | 220VAC 50/60Hz, single phase

2000W (including pump) |

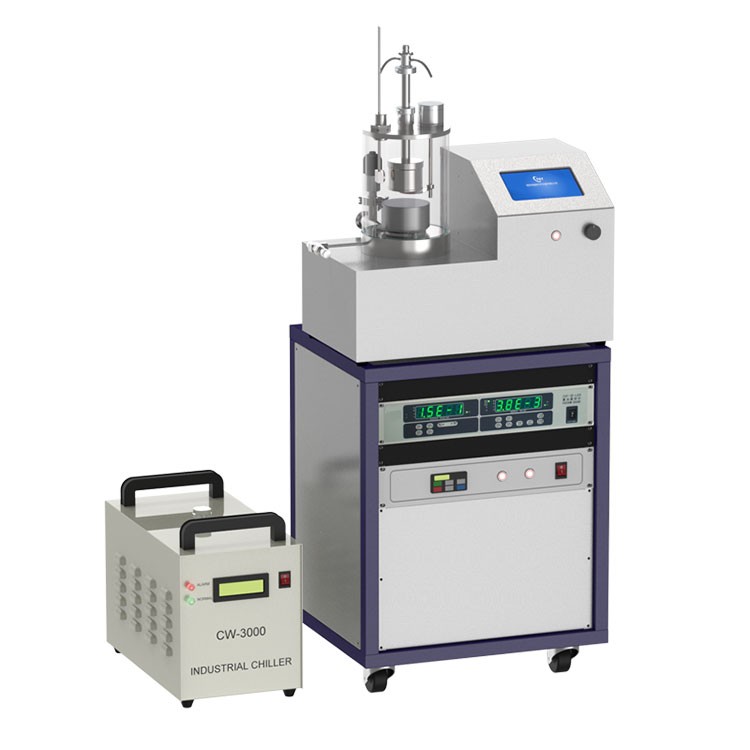

Source Power | Two sputtering power sources are integrated into one control box

DC source: 500W for coating metallic materials

RF source: 300W for coating non-metallic materials |

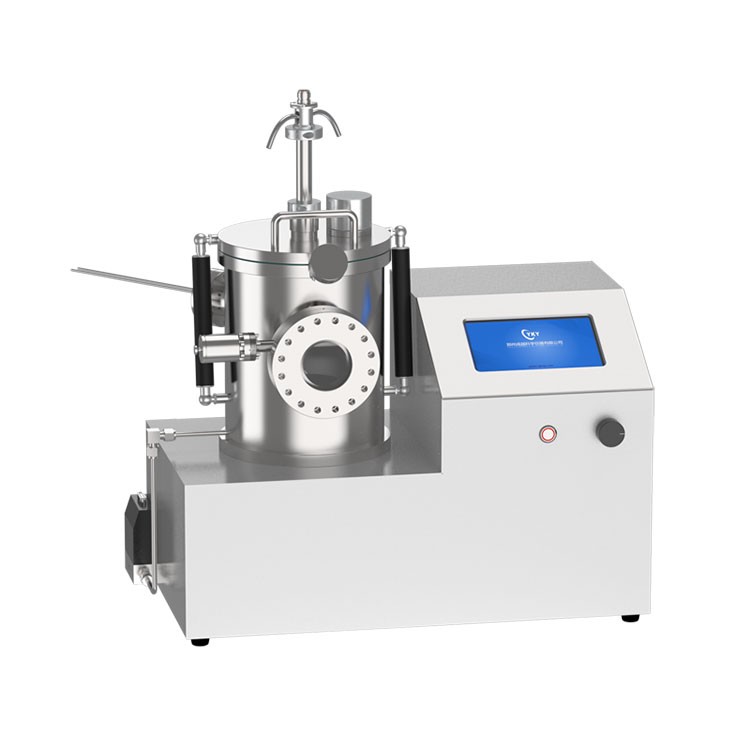

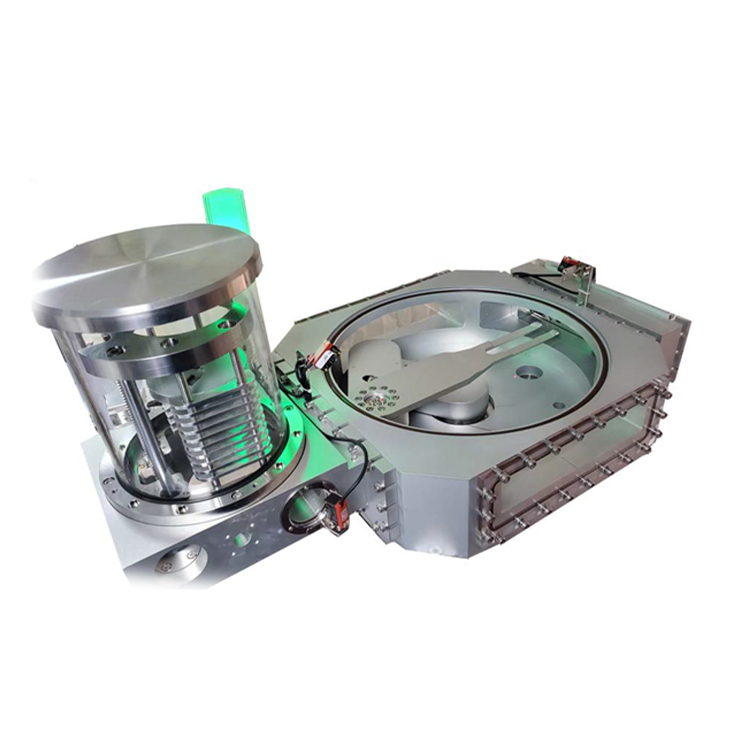

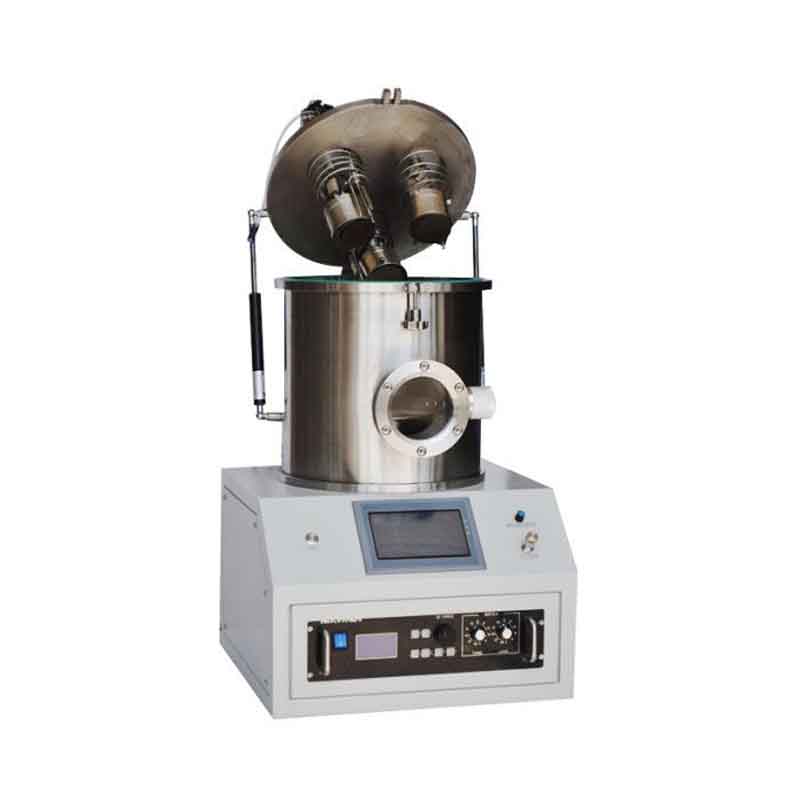

Magnetron Sputtering Head | Two 2" Magnetron Sputtering Heads with water cooling jackets are included

One is connected to RF source for non-conductive materials

The other one is connected to DC source for coating metallic materials

Target size requirement: 2" diameter

Thickness Range: 0.1 - 5 mm for both metallic and non-conductive targets (including backing plate)

One Cu and one fused SiO2 targets are included for demo testing

Recommend Coating Method<ol list-paddingleft-2"> |

| Vacuum Chamber | Vacuum Chamber: 300 mm Dia x 300 mm height, made of stainless steel

Observation Window: 100 mm diameter

Hinged type lid on top with pneumatic power pole makes target exchange easily |

Sample Holder | Sample holder size: 140mm dia. for. 4" wafer max

Sample holder rotation speed is adjustable: 1 - 20 rpm for uniform coating

The holder temperature is adjustable from RT to 500°C Max with accuracy +/- 1.0 °C |

Gas Flow Control

| Two precision digital MFC (mass flow controller) are installed to allow two types of gases to be filled in

Flow rate: 200 ml/min max. (0-200 SCCM)

Flow rate is adjustable on the 6" touch screen control panel |

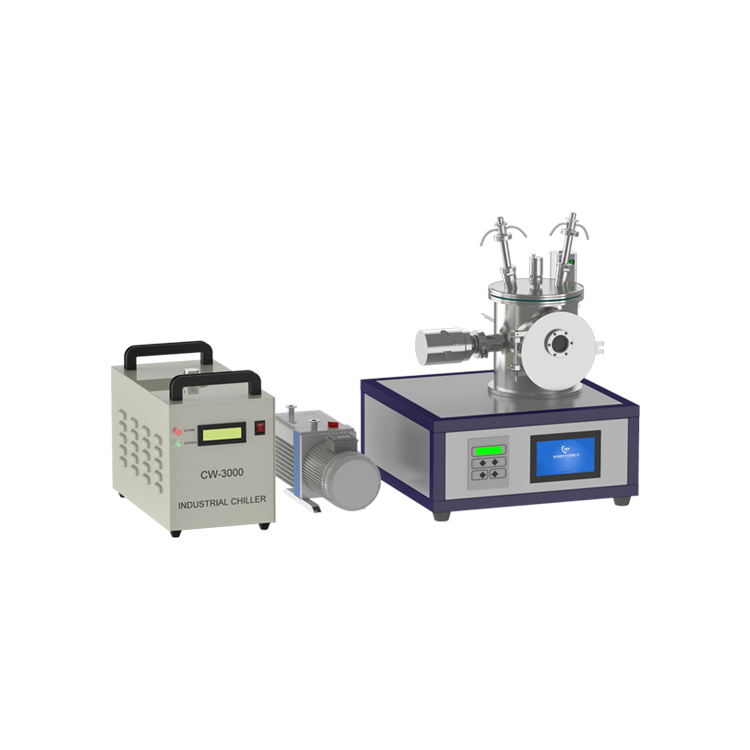

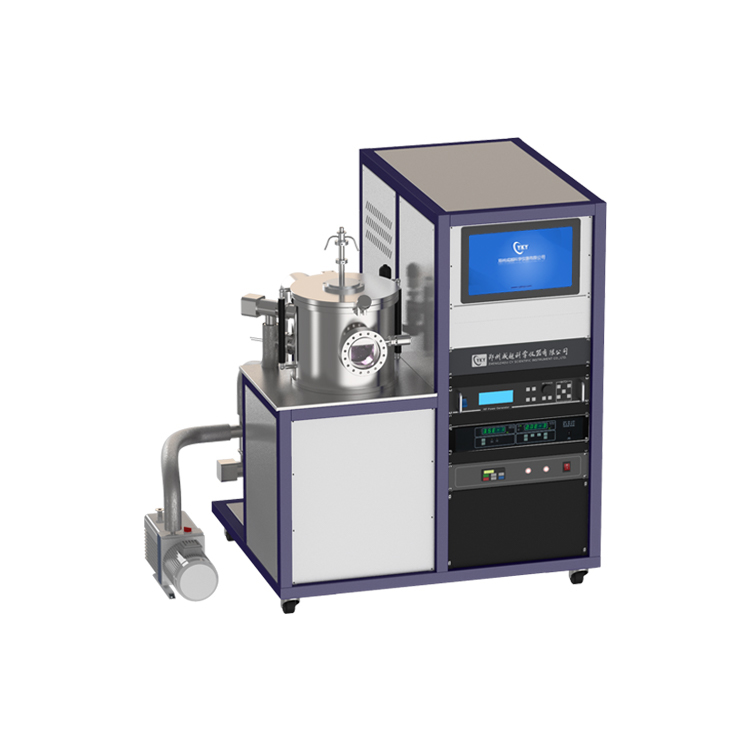

Vacuum Pump Station

| High speed turbo vacuum pump (made in Germany) is directly installed on the vacuum chamber for max. vacuum level

Heavy duty dual stage mechanical pump, 220 liters/minute (7.8CFM) is connected to turbo pump for faster pumping speed

Mobile pump station is included and the compact sputtering coater can be placed on top of station

Standard Vacuum Level: < 4x10^-5 Torr . Max. vacuum level: 10^-6 torr with chamber baking |

Water Chiller

| One Digital Temperature Controlled Recirculating Water Chiller is included for cooling both magnetron sputtering heads.

Refrigeration range : 5~35°C

Floowing Rate: 16L/minute |

Optionals | Precise quartz Film Thickness Monitor is available upon reuqest to built into the chamber to monitor coating thickness with accuracy 0.10 Å.

Pricesion Thin Film & Coating Analysis Systems with Measurement Capability is available for measure film thickness after coating. |

Overall Dimensions |

Lid closed: 48" × 28" × 32" Lid open: 48" × 28" × 37" |

| Net Weight | 200 kg |

| Warranty | One years limited warranty with lifetime support |

our company information:

Zhengzhou CY Scientific Instrument Co., Ltd.-founded in 2013 is a high and new technology enterprise registered in Zhengzhou,Henan province. We mainly supply the lab instruments for material research in labs like the cutting machine, milling machine, polishing machine, sintering furnace, mixing machine, glove box, film coating machine, etc.

contact information:

contact person: Tanya Wang

contact phone: 0086 371 55365392