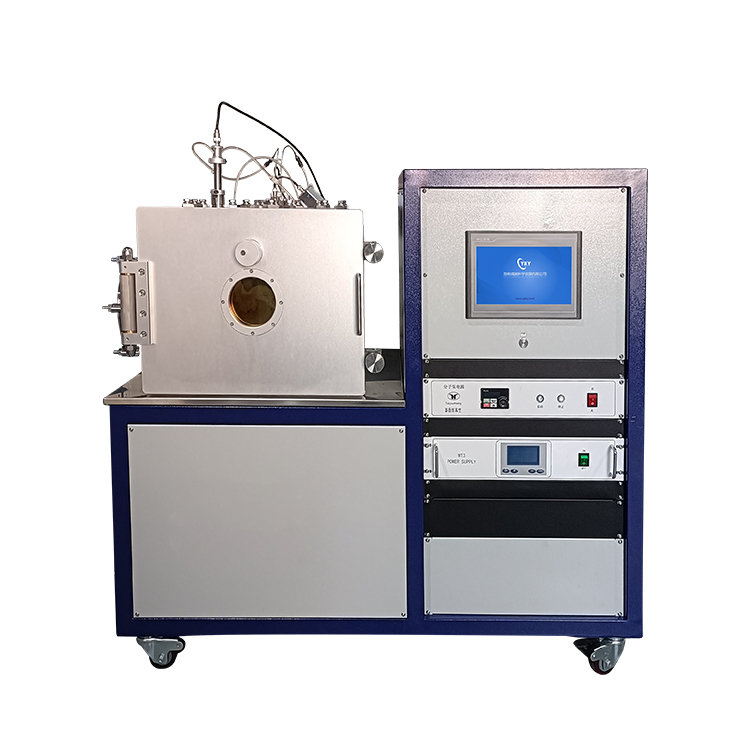

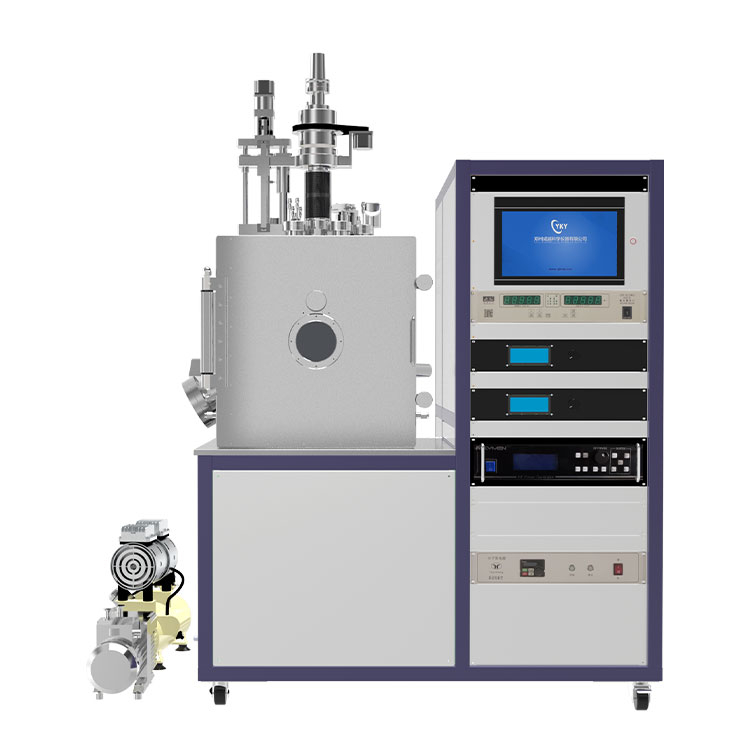

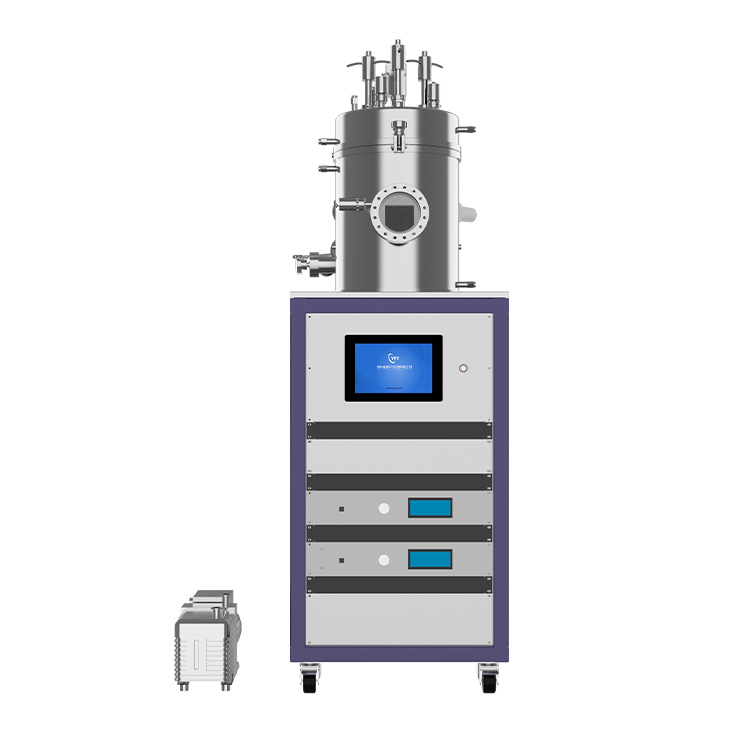

| Input Voltage | 220VAC, 10A, 50/60 Hz, single phase ( < 2500W) |

| Input Power | < 2000W (including pump) |

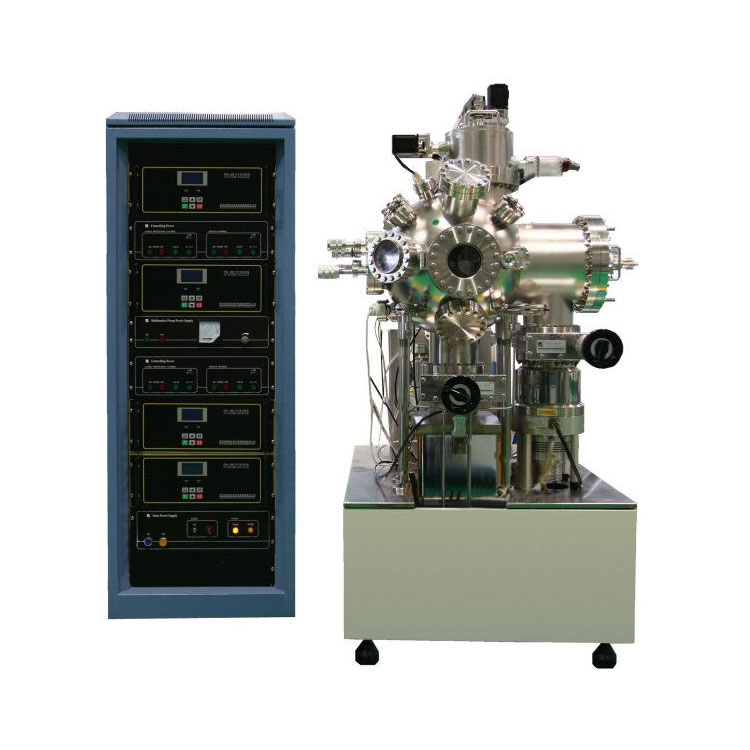

| Output Voltage (DC) | AC10V upto 100A Max. for thermal evaporationDC 3KV, 10mA for Plasma sputtering |

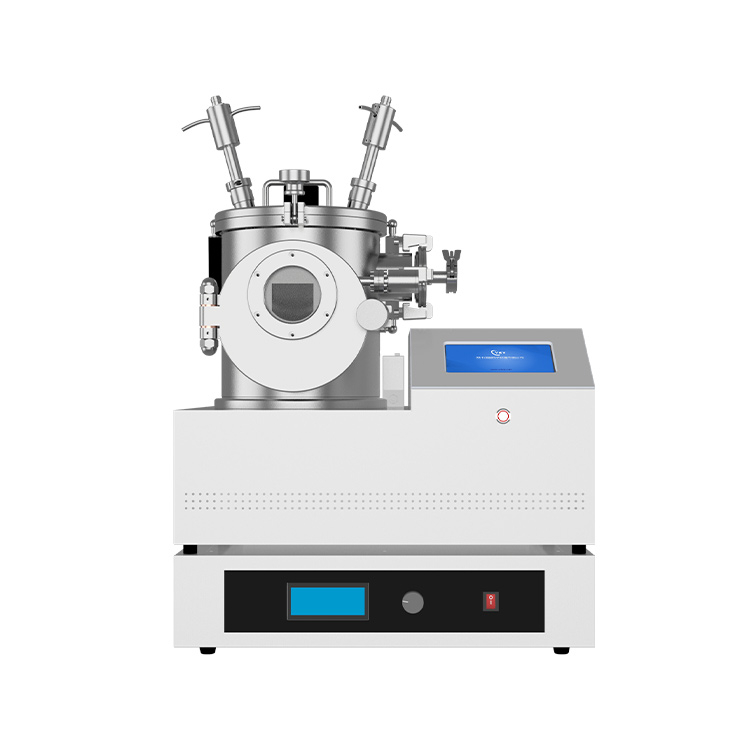

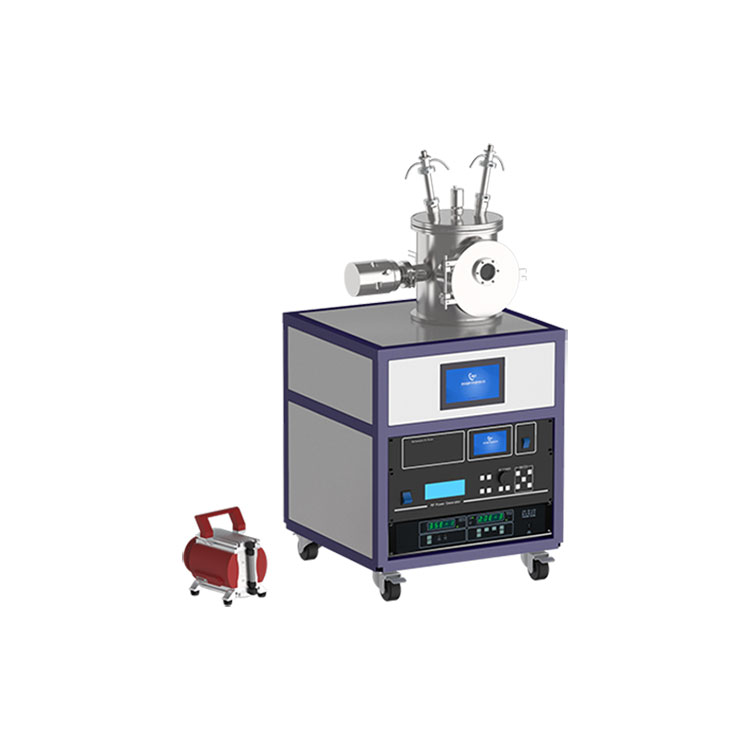

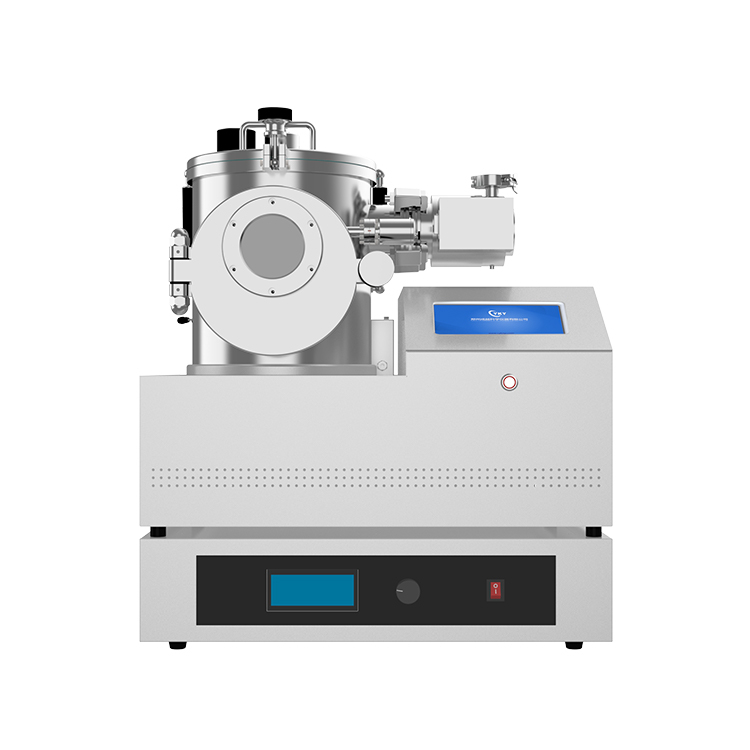

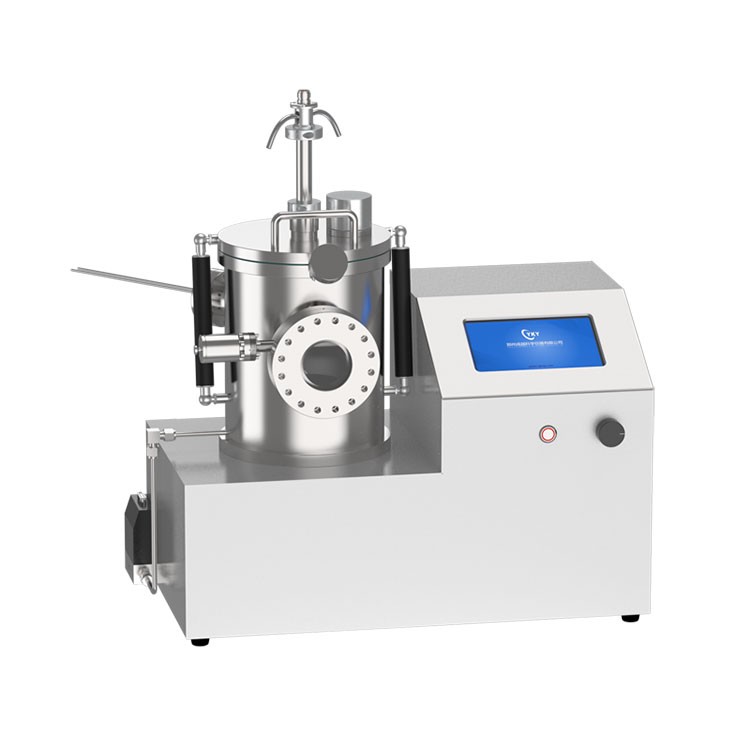

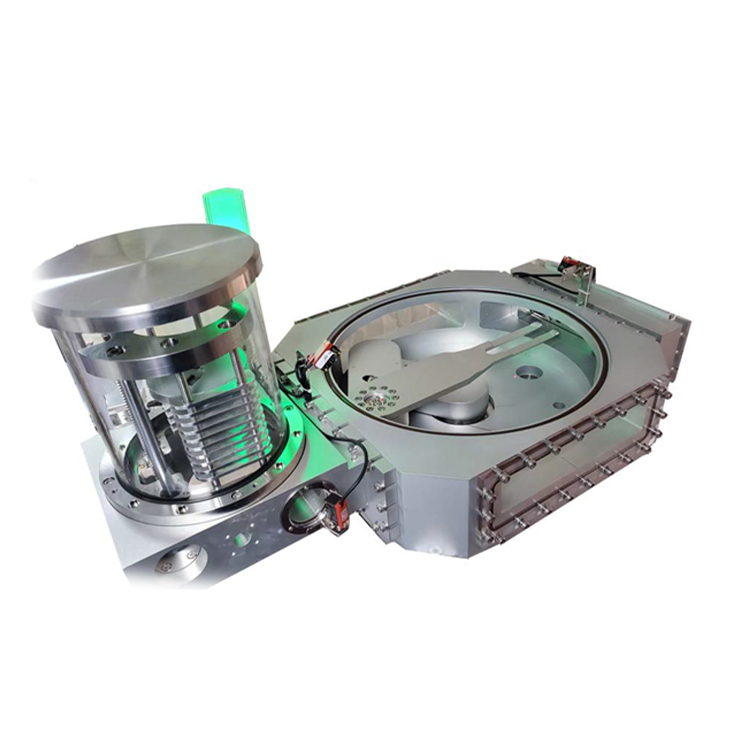

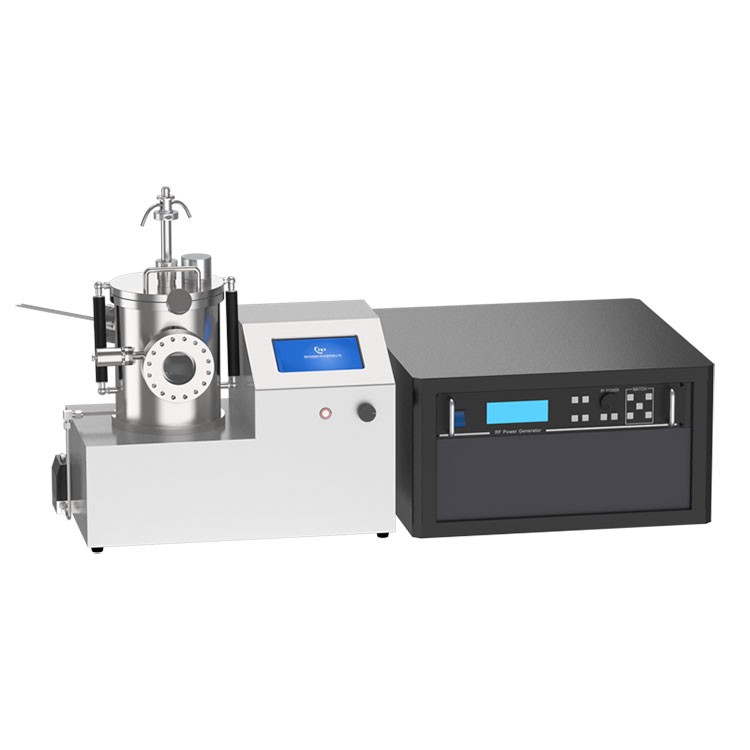

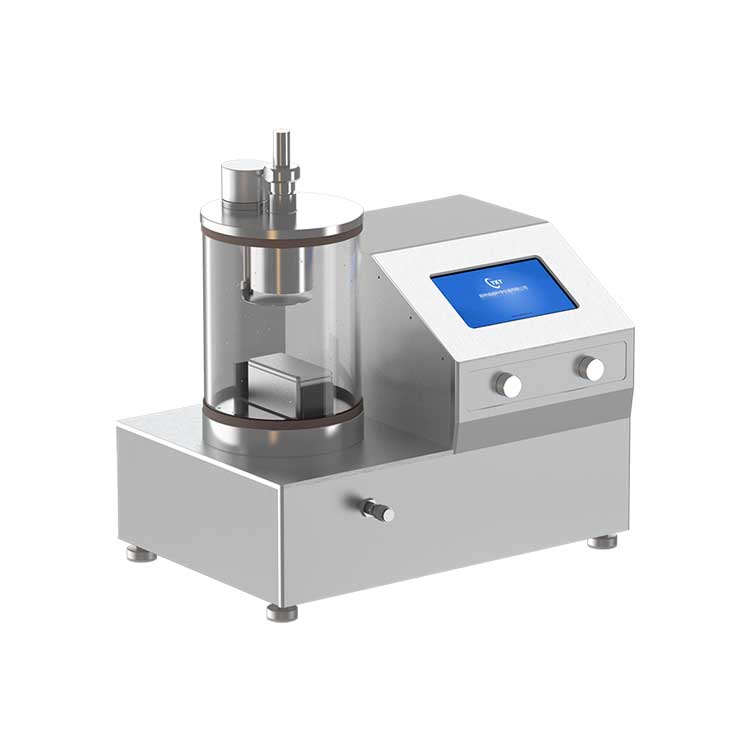

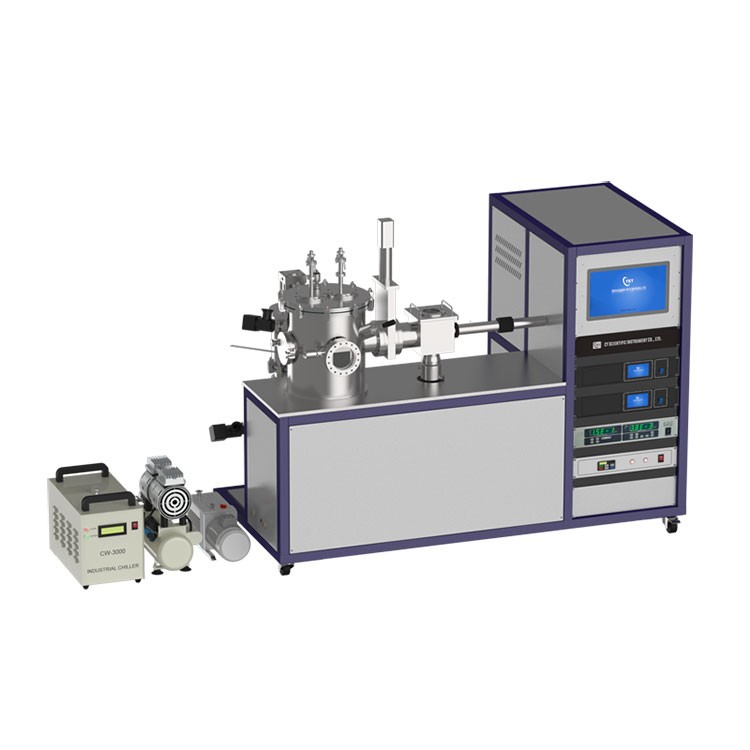

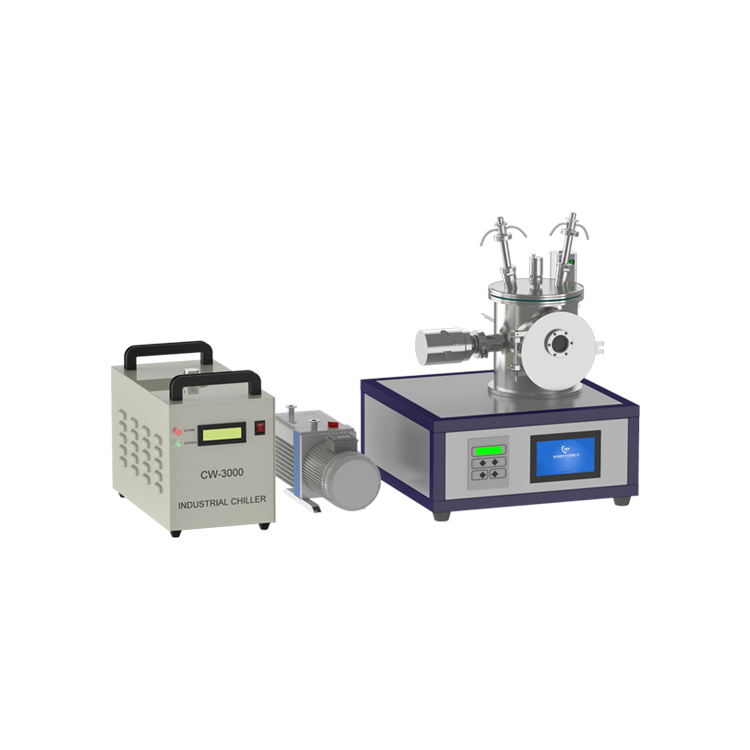

Vacuum Chamber

| Bell Jar made of pyrex glass250mm Dia. x 340mm HeightTwo inner glass tubes are included for radiation blockingOne is 88 mm ID x 140mm H for thermal evaporating The other one is 88 mm ID x 57mm H for plasma sputteringOne stainless steel mesh enclosure is included for blocking light radiation during thermal evaporation |

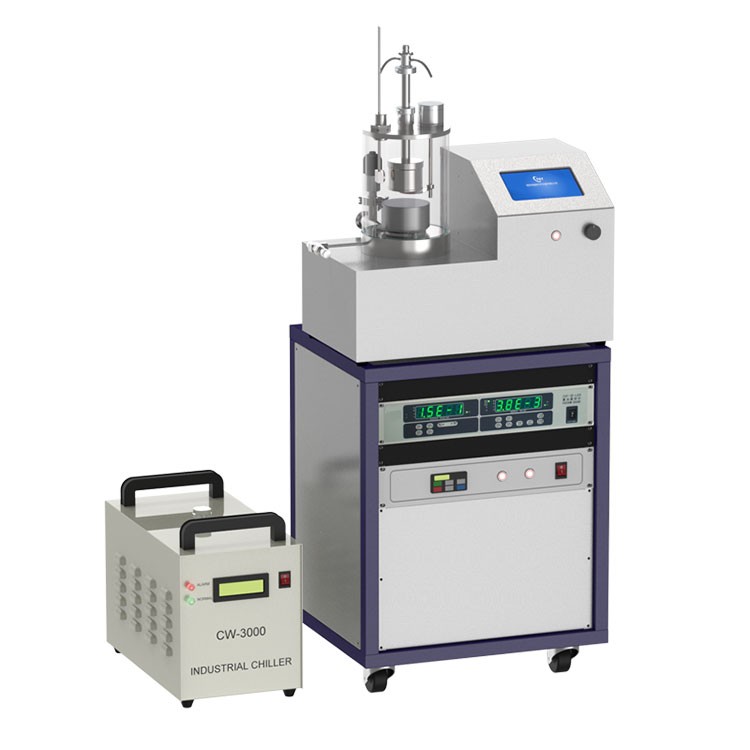

| Turbo Vacuum Pump | High-speed turbo vacuum pump system is installed bottom of the coaterVacuum speed: 600L/SVacuum level: 10e-6 torrEnvironmental working temperature: < 32°C |

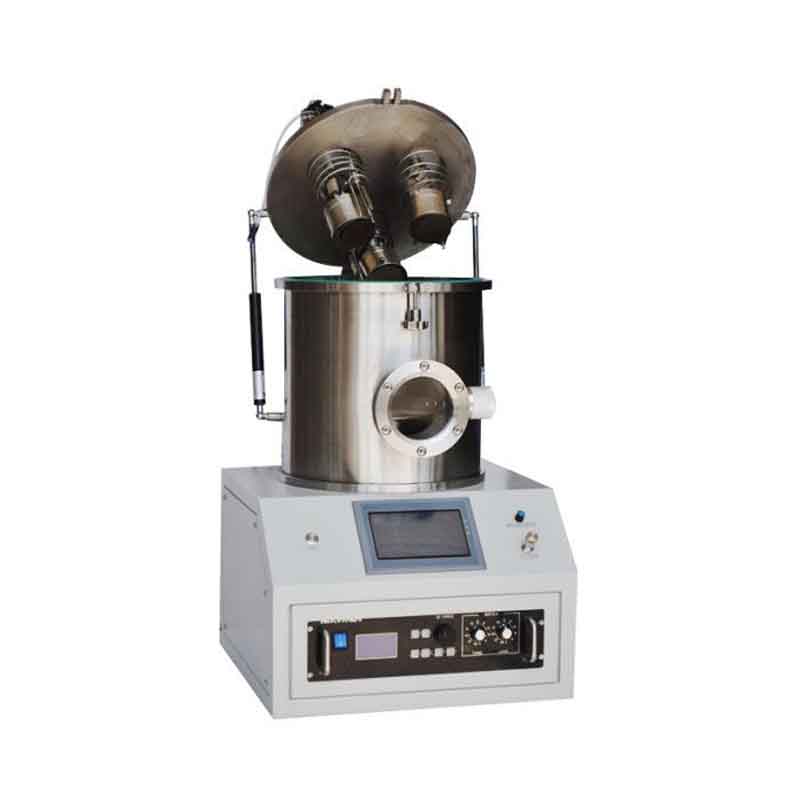

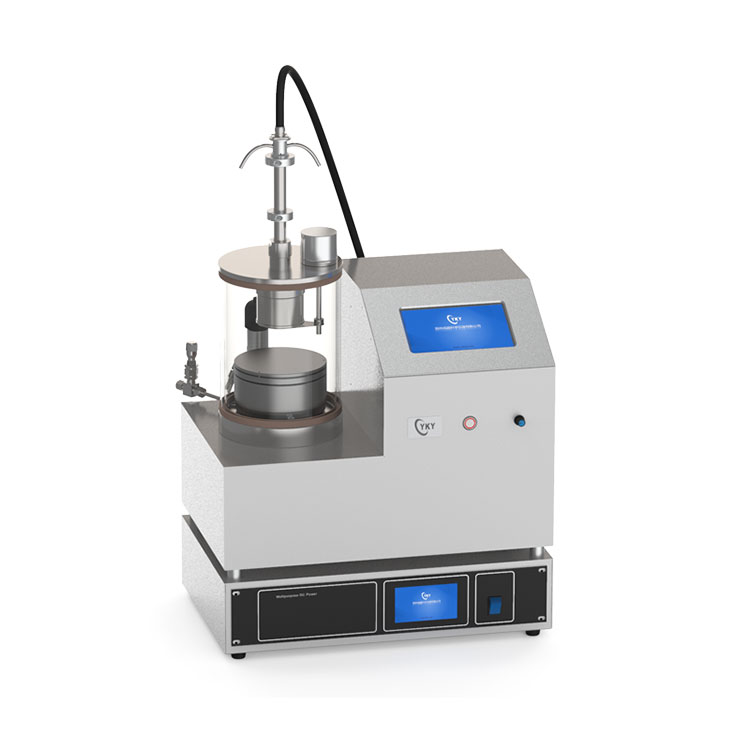

Coating Source Assembling

| Three sets of coating source assembling are included.

(1) Dual heating station for thermal evaporating ( Pic lower left)Can evaporate two kinds of materials in same time.Max. temperature can reach 1800ºC to evaporate almost all kinds of materials. Tungsten wire resistance heaters are included for immediate use.Spare Tungsten heater is available (2) One set for carbon coating Assembling two carbon rods are included for immediate use (3) One set for DC plasma sputteringOne gold target ( 38mm Dia x 0.12 mm thickness) is included |

| Control Pannel | Control Panel allows you choose coating method and adjust sputtering current and evaporation power

|

| Gas atmosphere | One needle valve installed to allow Ar gas flow to achieve better plasma coating |

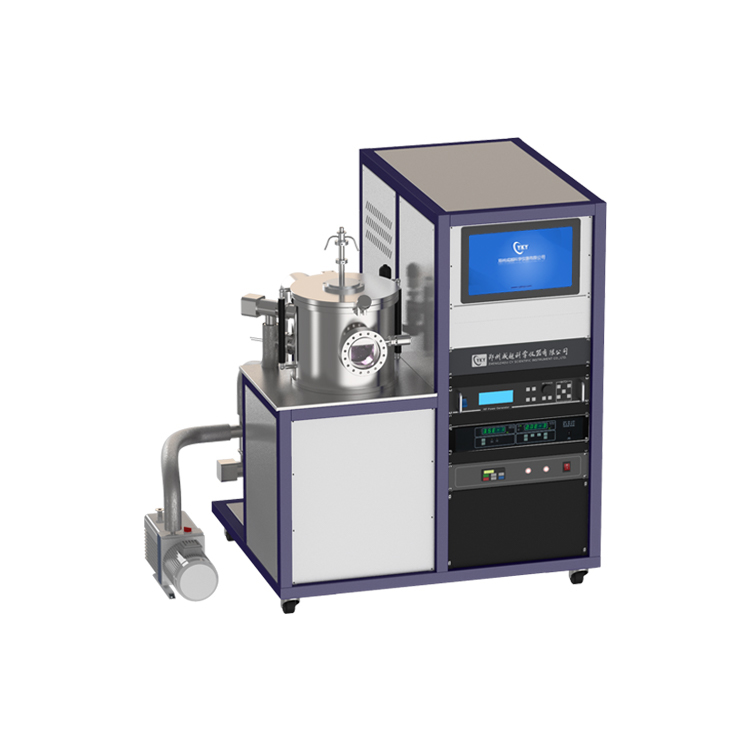

| Overall Dimensions | L800mm× W560mm× H1340mm |

| Net Weight | 150 kg |

| Shipping Weight & Dimensions | 400 lbs; 52"x40"x54" |

| Warranty & Certificate | One years limited warranty with lifetime support

CE certified |