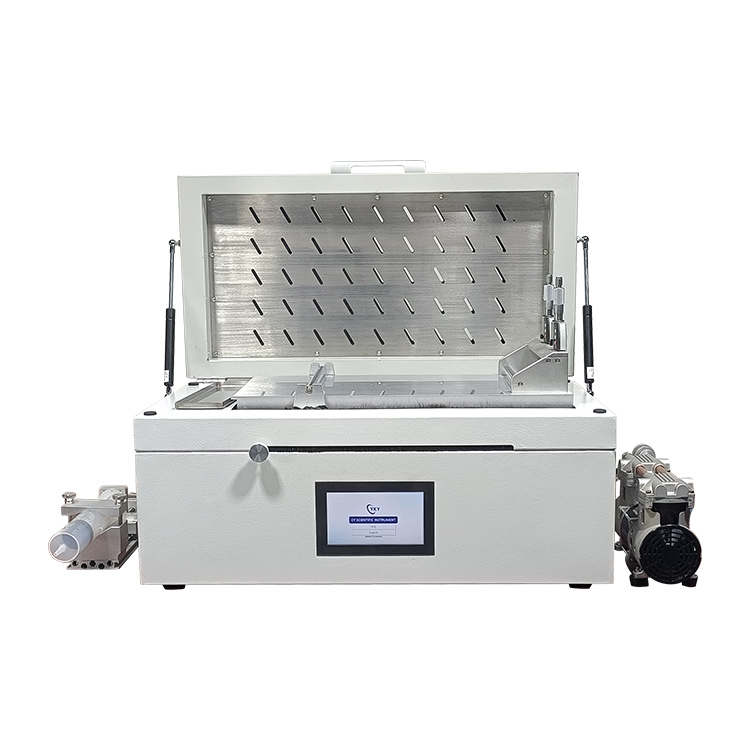

Lithium ion battery slit extrusion coater

Slit extrusion coater, can be continuous and intermittent coating and other types of coating requirements. The equipment has high coating precision, good consistency and stability, and is widely used in lithium-ion battery, graphene film, optical film, ceramic film, high-end tape and various functional film industries

Slit extrusion coater, can be continuous and intermittent coating and other types of coating requirements. The equipment has high coating precision, good consistency and stability, and is widely used in lithium-ion battery, graphene film, optical film, ceramic film, high-end tape and various functional film industries

Slit extrusion coater features:

Can achieve continuous, intermittent and other shapes of coating; Slit extrusioncoating method, high coating accuracy, good coating consistency; Substrate tension control, walking stability, configuration of deviation correction device; Hot air oven, upper and lower double-sided blowing, drying effect is high quality; PLC control,touch screen operation, easy to use

Slit extrusion coater technical parameters:

Coating head | 200mm width slot extrusion coater |

Minimum coating thickness | 5 microns (related to liquid viscosity) Built-in two micrometer heads, due to the modulation of the slit coater with the base of the interglandular |

Mechanical speed | Extrusion coating head movement speed 0.1um/S-1m /s |

Base material thickness | Max: 5mm |

Vacuum substrate | The coating machine substrate is made of aluminum alloy with uniform pores, which can generate vacuum through the built-in vacuum pump and adsorb the substrate to ensure the smooth sample |

Substrate size | L550*W240mm |

Substrate heating | Built-in heating element, can be heated up to 120C (heating time more than half an hour) |

Control system | All operation controls are integrated on the seven-inch touch screen for easy operation |

Oil-free vacuum pump | 50L/min |

Single channel injection pump | Flow rate: 0. 001ul /min -- 43.349ml/min |

Slit extrusion coater video: