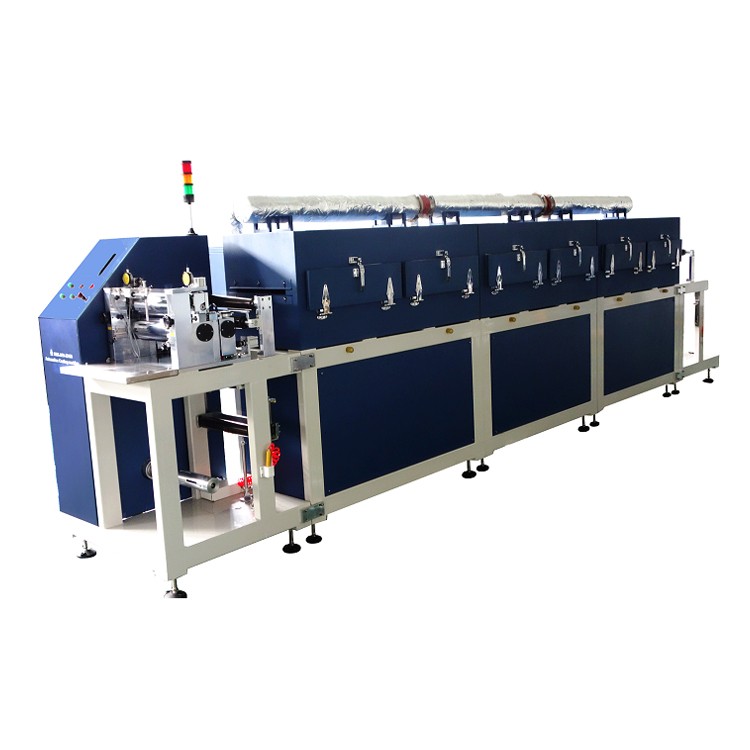

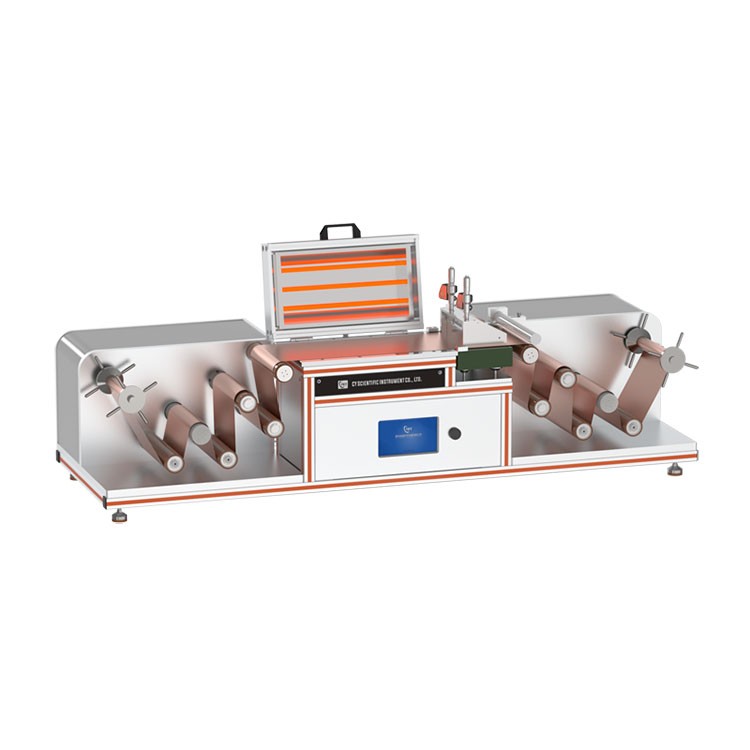

Working Voltage | 208 - 240 VAC, 50/60 Hz, three Phase (380VAC three phase is available upon request) |

Max. Power Consumption | 30 KW (50A Air breaker required) |

Compressed Air | 0.5-0.8 MPa is required (Air compressor not included. ) |

Reeling/Unreeling Diameter | · 350mm O.D Max. · Reeling/Unreeling shaft diameter: 3 inches |

Coating Width | 350mm Max. |

Coating Speed | Max.5000mm/min |

Coating Heads (please select in the Product Options)

1.Reverse Comma Blade

2.Doctor Blade 3.Tape casting 4.Slot Die 5.Micro-Gravure | Doctor Blade Coating

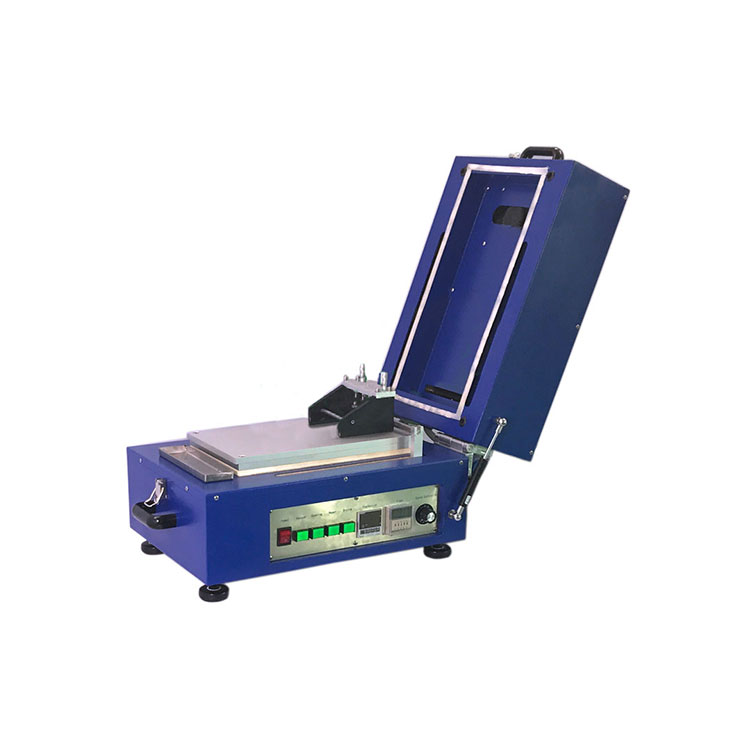

| · Continuous coating mode only · Coating thickness range: 10~200um ( dried film ) · Typical slurry viscosity range: 500~10000 mPa.s · Precision: ±5μm (gap adjustment solution 1um); Edge to center thickness tolerance +/-8um · Auto-slurry feeder with 2 liters tank is available at extra cost. |

Reverse Comma Blade (Transfer Coating) | · Two available coating modes (continuous and intermittent) selectable on the control panel. · Coating thickness range: 30~200um (dried film) · Typical slurry viscosity range: 500~10000 mPa.s · Precision: ±3μm; Edge to center thickness tolerance +/-5um · Auto-slurry feeder with 2 liters tank is available at extra cost |

Cast Coating | Tape casting technique is ideal for handling thicker slurry 5000~20000 mPa.s and thus thicker film coating is achievable (up to 1000um) Continuous coating mode only Precision: ±5μm (gap adjustment solution 1um); Edge to center thickness tolerance +/-8um Slurry feeding screw pump with 4 liters tank is included.

|

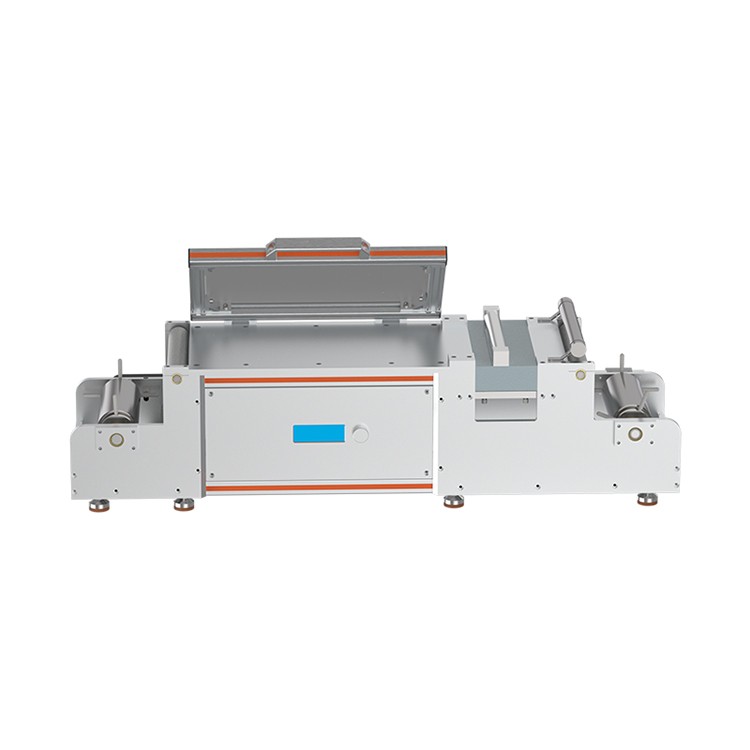

Slot Die coating | The slot die is perfect for uniform film coating of 1 micron and up to 200-micron thickness. By changing the shim size with various patterns, you would be able to produce continuous, intermittent, or even grid coatings that match the shim patterns. MSK-156 slurry feeding screw pump with 4 liters tank is included, please click underline to view details Minimum thickness & precision:1 µm (dried film), ±1% Typical slurry viscosity range: 200~10000 mPa.s

|

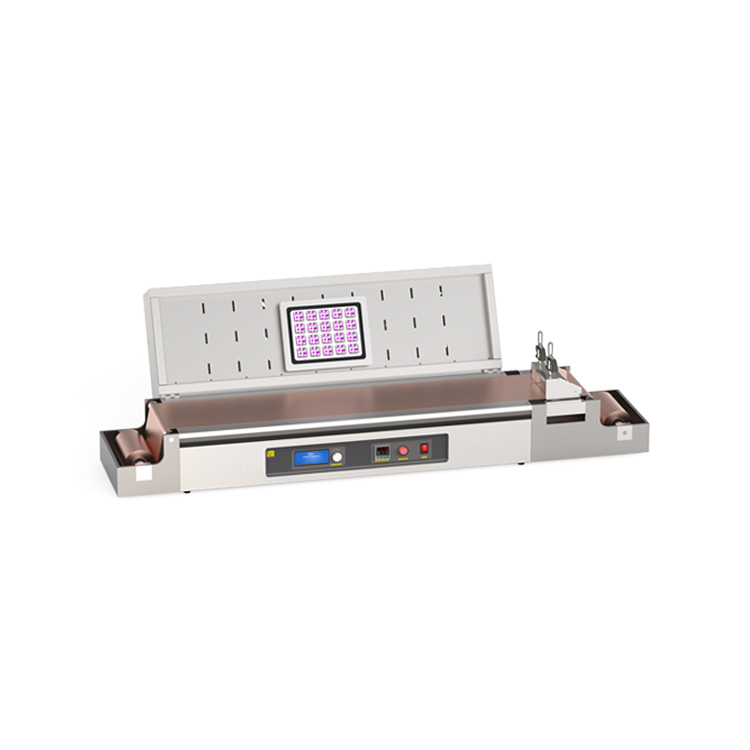

Micro-Gravure Coating | · Continuous and intermittent coating modes are available for the user. · Coating thickness range: 1~3um (dried film) · Typical slurry viscosity range: 30~1000 mPa.s · Auto-slurry feeder with 2 liters tank is included. |

Convection Drying Oven | Three zone design with independent temperature controllers. Air flow rate:9.5/2800 (cm³/RPM) max. for a single zone, flow rate adjustable Drying temperature: 150°C max±5℃ Power Consumption: 9KW for single zone (27KW total) Heater length: 1.5m for single zone (4.5m total)

|

Product Dimensions | L6600mm x W1200mm x H1850mm |

Net Weight | 12.3t |

Warranty | |