Control Panel | Working Voltage: 110-240V AC Max. Power Consumption: 50W Detachable Digital Controller offers flexibility Programmable temperature controller, Forced air fan power adjustor, Temperature limit & alarm indicator, Incubate and dry function switch are included.

|

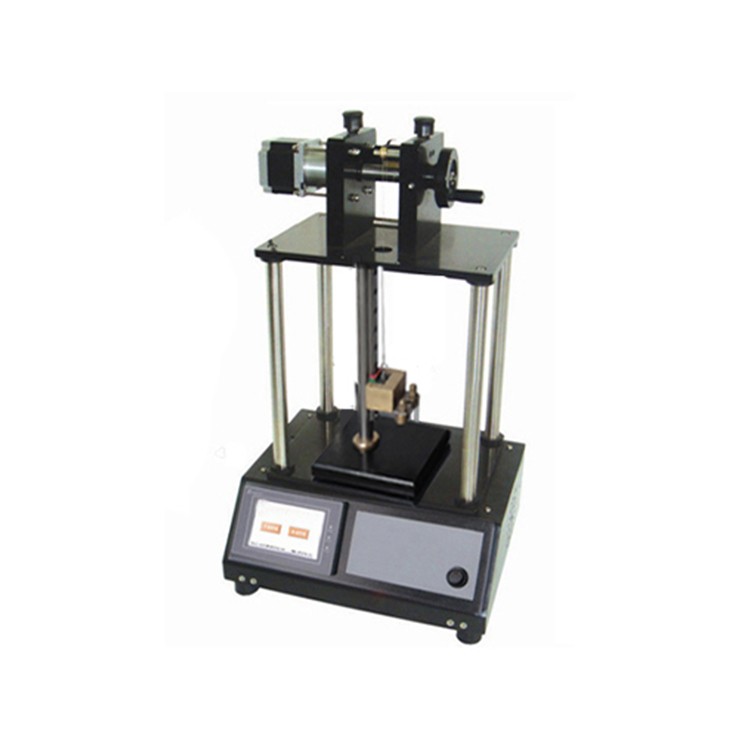

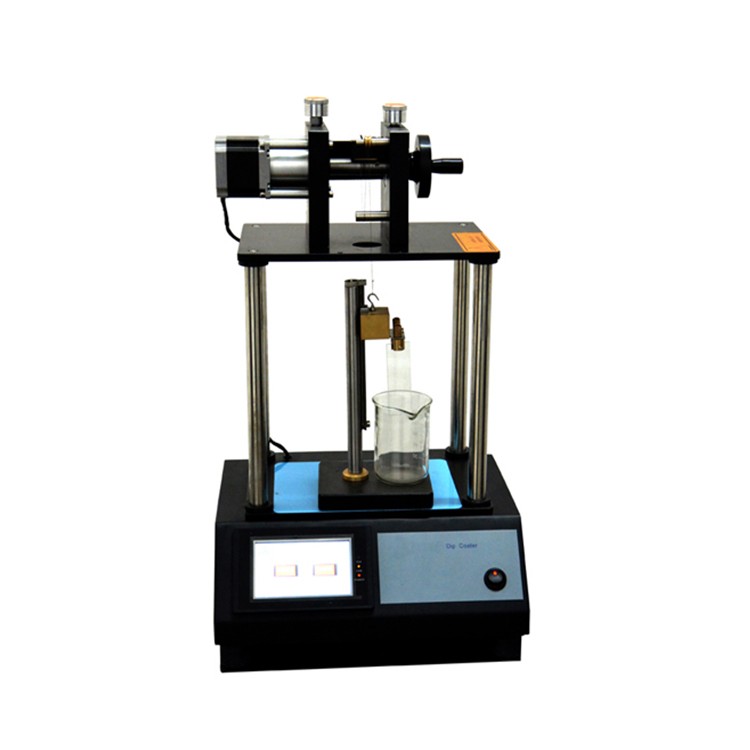

Traveling Distance | 0-250 mm Adjustable |

Dipping/Pulling Speed | 1-200 mm/min Adjustable |

Max. Working Temperature | 100°C (+/- 1.5°C accuracy) |

Solution Container | One Polypropylene dip tank is included with dimensions of 17.25''(W)×2''(D)×9.5'(H) Optional: temperature controlled recirculating pump for the coating slurry can be added inside chamber and tank at extra cost. |

Max. Sample Size | 16" x 9" |

Max. Sample Weight | 5 kg |

Dipping/Pulling Motor | Stepping Motor |

Oven | Working Voltage: 208-240V AC Max. Power Consumption: 2300W Chamber Dimensions: 500mm(L)×450mm(W)×550mm(H)-- 124 Liter Inner Material: Stainless Steel

|

Product Dimensions | 636mm(L)×680mm(W)×915mm(H) |

Compliance | CE Certified |

Warranty | One year limited with lifetime support |

Net Weight | 91 kg (200 lbs) |

Application note | The liquid solution is placed in the controlled temperature oven with +/-1.5°C tolerance from room temperature to 100°C. Please keep warm at least half hour after the temperature reach the set point on the digital temperature meter to ensure an equilibrium temperature distribution in the liquid solution |